Scooterbum

Addicted to ArboristSite

Seems to me they move anything that's off topic, political, firewood or joke related.

Why not the modded work saw and hot saw stuff?

Why not the modded work saw and hot saw stuff?

Doesn't this belong in the "Modded Work Saw" forum?

Isn't that what it's for?

Well, if this is the way you match your bottom transfer in for transfer flow, you have alot to learn.:shame: It's all about flow my friend!

They may have come along way, but they still look like alot of work! No big deal for a pro port grinder like you, plus you might make a few more bucks with the added grinding. The average guy might be better off avoiding this cylinder and go to the OEM. Are you going to have someone else build one also for a real comparison?

Doesn't this belong in the "Modded Work Saw" forum?

Isn't that what it's for?

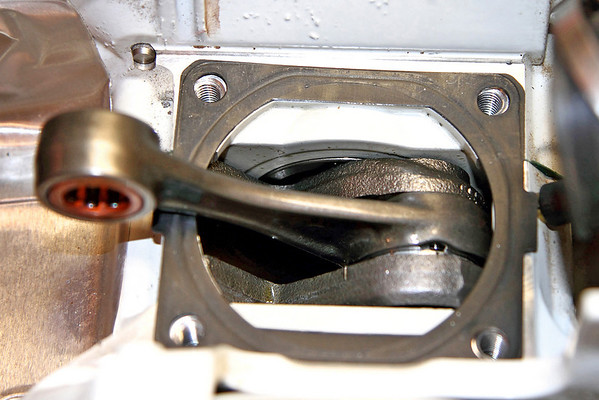

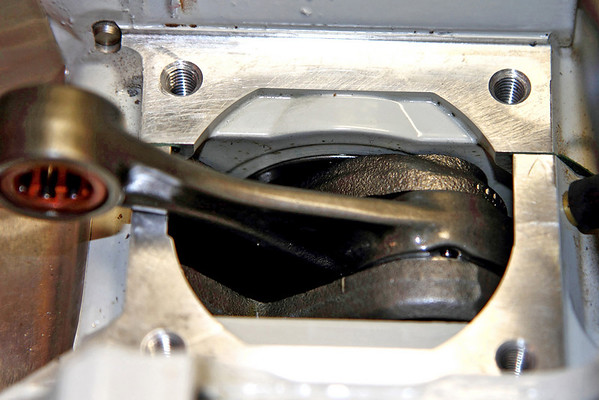

There's nothing to be gained by taking this lower, due to the shape of the case. The cylinder is already out wider than the case.

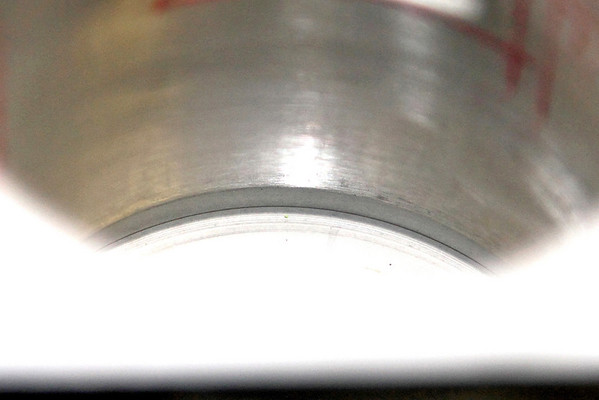

I won't be doing a popup on this saw, but if I were, there might be an issue here. It appears to me that the NiSi may not go to the top of the bore, by approxiamately .170". Subtract a squish of .020", and that's still .150". That will still have the rings riding onto this area .030". Hopefully this is simply unhone NiSi. I can feel no ridge whatsoever, so hopefully that's the case.

Sounds good! Once again, these bb kits are a good option,especially with your touches. Get r in some wood!!!

I just picked up a 066 thats gonna need atleast a piston so i figured i would just go ahead and get the BB kit for it. Thanks for the pics and comments about the quality of the product and sharing about the port work you did. After seeing how little you could take off, i probably wont mess with trying to port mine and risk screwing it up. You saved me some time and trouble. Thanks, great thread!

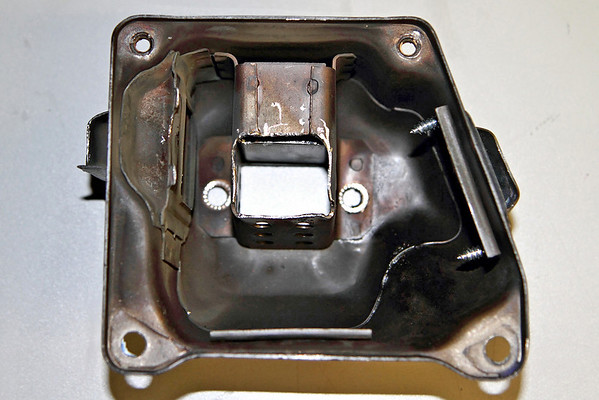

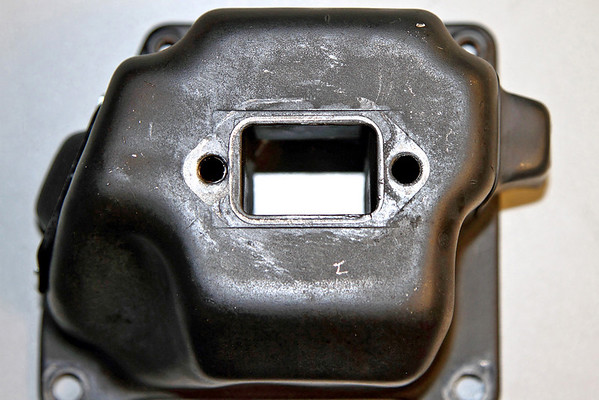

The factory exhaust outlet is tiny, mayby 3/8" at most.

This "cage" was completely closed on the end. All exhaust has to go through the small holes on the sides. I opened up the cage so that it's a straight shot through.

I then opened op the outlet as far as the deflector covers.

I then added an additional port. This port wouldn't have been required for a work saw, but added it anyway. A spark arrestor screen can be added if need be.

Enter your email address to join: