You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Porting advice Husqvarna 181/288 hybrid

- Thread starter Will Kraemer

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Will Kraemer

WillBilly

Yotaismygame

Juiced Saws #GetJuiced

Excellent! What lathe is that? After you get the base done read the timing numbers again. If the intake is anything less than 75 you should lower the jug just a little more. Decide where to take it off based on what the exhaust ends up at. I've always wanted to build a saw this way but never do it.

Yotaismygame

Juiced Saws #GetJuiced

Explain that piston holder. I always just put it directly in the 4 jaw without problem, but that holder looks cool.

Will Kraemer

WillBilly

The lathe is an old LeBlond Regal. (I'm a student shop technician at Cal Poly university Ag engineering and am lucky enough to have mills, lathes, cnc's to tinker around with)

I saw that piston holder on youtube by Timberwolfsaws , made mine out of a delrin plastic cylinder, turned and faced it, then drilled a 1/4 hole through it. used a parting tool to cut the grove where the piston skirts sit. Then machined a brass piston pin with a 1/4-20 threaded hole in the middle. Worked really well. I can take more pictures next time I head back to the shop.

Currently, It has .072" of squish with no base gasket. I was thinking of going .020" for final squish. Do you think that would work well Yota?

Also, the bottom of the cylinder bore (that extends into the case), touches the inside of the crankcase not allowing it to fully seat downwards on the flywheel side. I believe I have to machine about .070" off of that part in order for it to sit flush.

I saw that piston holder on youtube by Timberwolfsaws , made mine out of a delrin plastic cylinder, turned and faced it, then drilled a 1/4 hole through it. used a parting tool to cut the grove where the piston skirts sit. Then machined a brass piston pin with a 1/4-20 threaded hole in the middle. Worked really well. I can take more pictures next time I head back to the shop.

Currently, It has .072" of squish with no base gasket. I was thinking of going .020" for final squish. Do you think that would work well Yota?

Also, the bottom of the cylinder bore (that extends into the case), touches the inside of the crankcase not allowing it to fully seat downwards on the flywheel side. I believe I have to machine about .070" off of that part in order for it to sit flush.

Yotaismygame

Juiced Saws #GetJuiced

Pictures would be great of that holder. I’ll have to make one.

Yes you are correct on everything. Make sure you bevel the edges of the cylinder extension after you cut it down. Also be prepared to grind on the case where the carb sits. This saws gunna be a runner!

Yes you are correct on everything. Make sure you bevel the edges of the cylinder extension after you cut it down. Also be prepared to grind on the case where the carb sits. This saws gunna be a runner!

Will Kraemer

WillBilly

Here are the pictures of the piston holder. Haven’t been able to go to the shop this week so wasn’t able to get them to you sooner.

Come this next week I should be able to machine the base down and see what my numbers are.

Sent from my iPhone using Tapatalk

Come this next week I should be able to machine the base down and see what my numbers are.

Sent from my iPhone using Tapatalk

Yotaismygame

Juiced Saws #GetJuiced

Here are the pictures of the piston holder. Haven’t been able to go to the shop this week so wasn’t able to get them to you sooner.

Come this next week I should be able to machine the base down and see what my numbers are.

Sent from my iPhone using Tapatalk

I will definitely be making one of these.

Will Kraemer

WillBilly

Machined the base down .049” to get a .020” squish with the base gasket I’m using. Also faced the cylinder extension down. The coating inside the extension chipped a little so I think I’ll clean that up with some diamond burs.

Yotaismygame

Juiced Saws #GetJuiced

Thanks for the update. Chipping plating is the biggest issue with porting AM cylinders. I did't find the HW cylinder I used too bad. Burr will clean that up for sure.

Will Kraemer

WillBilly

Hopefully I’ll have time to get the new numbers tonight

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Chamfer the outside of the extension also so it fits the rounded area above the bearing pockets. I usually chamfer about 1/3 to 1/2 of the thickness depending on the model

Will Kraemer

WillBilly

So I chamfered the inside a little and ground off the hwy letters. Still need to do some more chamfering on the inside and outside of the extension. But here are the numbers with no base gasket.

Ex: 160...100atdc

Tr: 120...120atdc

In: 150...75btdc

Bd: 20

Squish at .018” with no gasket.

Yota you were spot on with your machining suggestions. Thanks!

Sent from my iPhone using Tapatalk

Ex: 160...100atdc

Tr: 120...120atdc

In: 150...75btdc

Bd: 20

Squish at .018” with no gasket.

Yota you were spot on with your machining suggestions. Thanks!

Sent from my iPhone using Tapatalk

Yotaismygame

Juiced Saws #GetJuiced

So I chamfered the inside a little and ground off the hwy letters. Still need to do some more chamfering on the inside and outside of the extension. But here are the numbers with no base gasket.

Ex: 160...100atdc

Tr: 120...120atdc

In: 150...75btdc

Bd: 20

Squish at .018” with no gasket.

Yota you were spot on with your machining suggestions. Thanks!

Sent from my iPhone using Tapatalk

YESSSSSS!

Will Kraemer

WillBilly

I should have some free time in the next couple of days to start porting it. I plan on leaving the exhaust and transfers at 100 and 120. Should I lower the intake down to 80?

Yotaismygame

Juiced Saws #GetJuiced

78-80 should work out

Will Kraemer

WillBilly

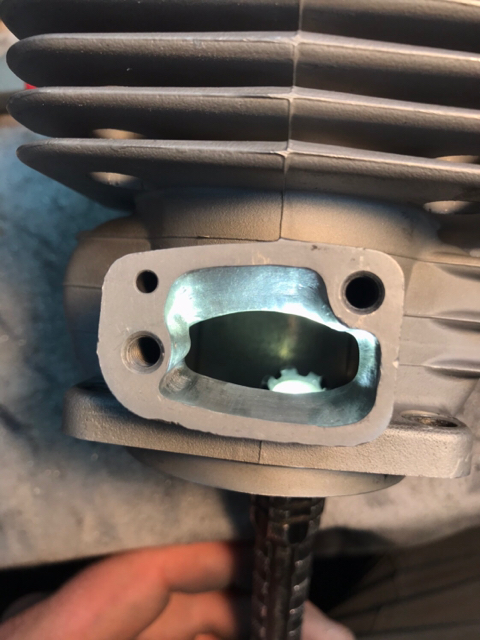

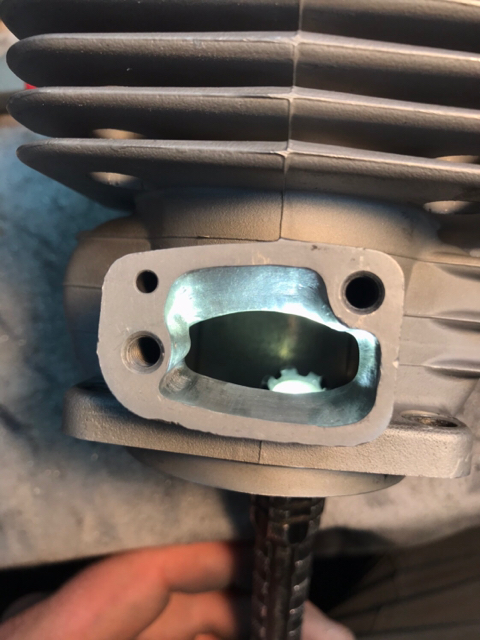

How’s this looking for my first port job?

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Yotaismygame

Juiced Saws #GetJuiced

It looks decent. You could really square up the corners better on the intake. Are you planning on polishing? Make sure you bevel the edges well. Especially on the exhaust side.

Will Kraemer

WillBilly

I plan on polishing them using a small file and sand paper. By squaring you the ports, does that just allow a larger volume of charge to enter the crankcase? Is a .05” chamfer alright?

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Yotaismygame

Juiced Saws #GetJuiced

Yes, intake side it can be completely square but the exhaust side it should have a nice taper to the top of the port for ring longevity. If the intake side is more square the port will completely open all at once. If you flipped the intake port over that would look better. But now we are getting pretty specific. Marginal differences IMO.