Will Kraemer

WillBilly

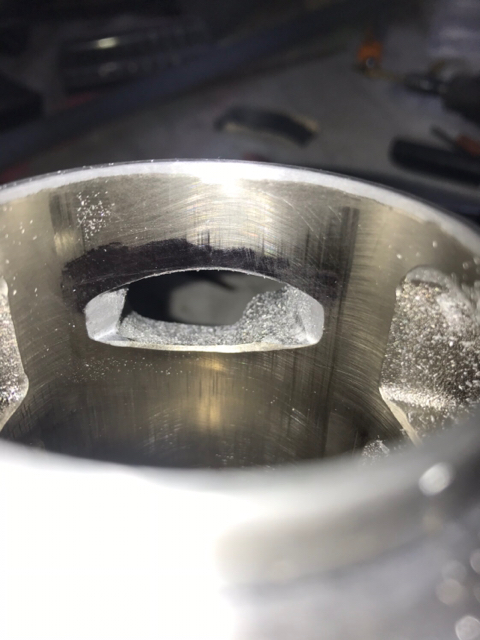

When you say flipping the intake port, are you talking about making the floor of the intake slightly flatter? which I could achieve by squaring off the bottom corners of it.

yesWhen you say flipping the intake port, are you talking about making the floor of the intake slightly flatter? which I could achieve by squaring off the bottom corners of it.

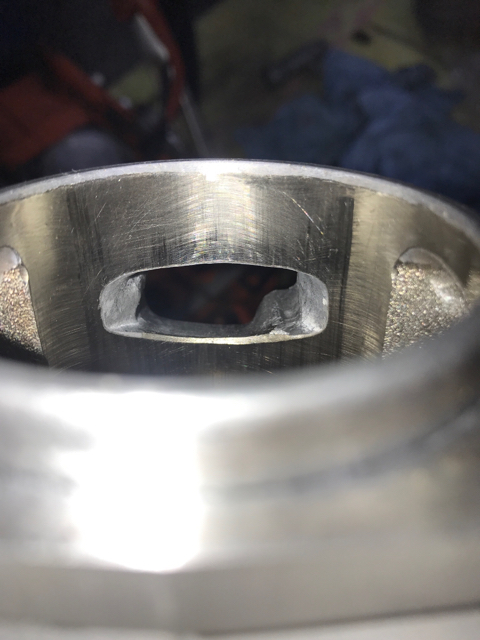

On mine I had to grind a little under the carb to get it all lined up.So finished up matching the exhaust and intake only to find a small crack in the intake block. So hopefully I’ll get the new one in a week.

One thing I noticed was interference with the screws on the bottom of the carb and case that causes the cylinder tone about 1/16” high from sitting flush. Is it fine to grind pretty deep Into the case right below the carb?

Also, on the faces of the intake block, it has some ridges that surround the impulse and the main air tract. In order to get the intake block to match up with the ported intake, it will require grinding past that ridge.

Am I able to sand that ridge flush with the face of the block and make a gasket to seal it?

While I wait for the intake block, I will Work on filing the flywheel key to advance the timing.

On mine I had to grind a little under the carb to get it all lined up.

Enter your email address to join: