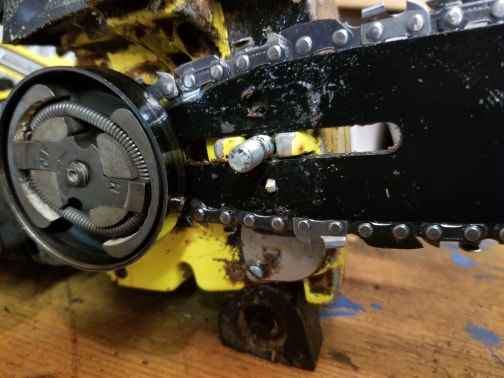

Hi all. So, the other week, I took my 'Poulan' 2300 apart to clean it. Came apart, cleaned, and reassembled as per the way it was. However, when last used a year or so ago, it was cutting fine then it had some chain problems that I recalled while talking with my dad. So fas forward to today. We were outside cutting up some wood for bonfires and I had the chain adjusted as per factory. I cut for about 5 minutes with no problems. Then I took the cover off the top to adjust the idle and it is then we noticed this behaviour. Dad first thought the chain brake was on, but I assured him it was not. The saw just bogged down when giving it throttle. So I shut it off, and he grabbed the chain and it was tight as all heck. We loosened teh bar off, and gave the chain some slack. Tightened it up again. STrated it up, cut a couple small branches (3-4") and it bogged down again. Chain was tight again. Loosened it again, and history repeated itself again. We are at a loss right now. If anyone would happen to know what it causing this, I would appreciate to hear it as we are looking forward to fixing this saw. Thank you in advance for your time.

In case it makes a difference, we loosened off the nut inside the handle (visible), then adjusted chain tension in front of the saw on teh other side of the blade.

In case it makes a difference, we loosened off the nut inside the handle (visible), then adjusted chain tension in front of the saw on teh other side of the blade.