Stumpys Customs

Stumpbroke

This is my current project I have goin on. A big red SOLO 694. Same thing as a Dolmar 9010. This is a ground up build with new bearings, seals, top end, oiler rebuild, and porting.

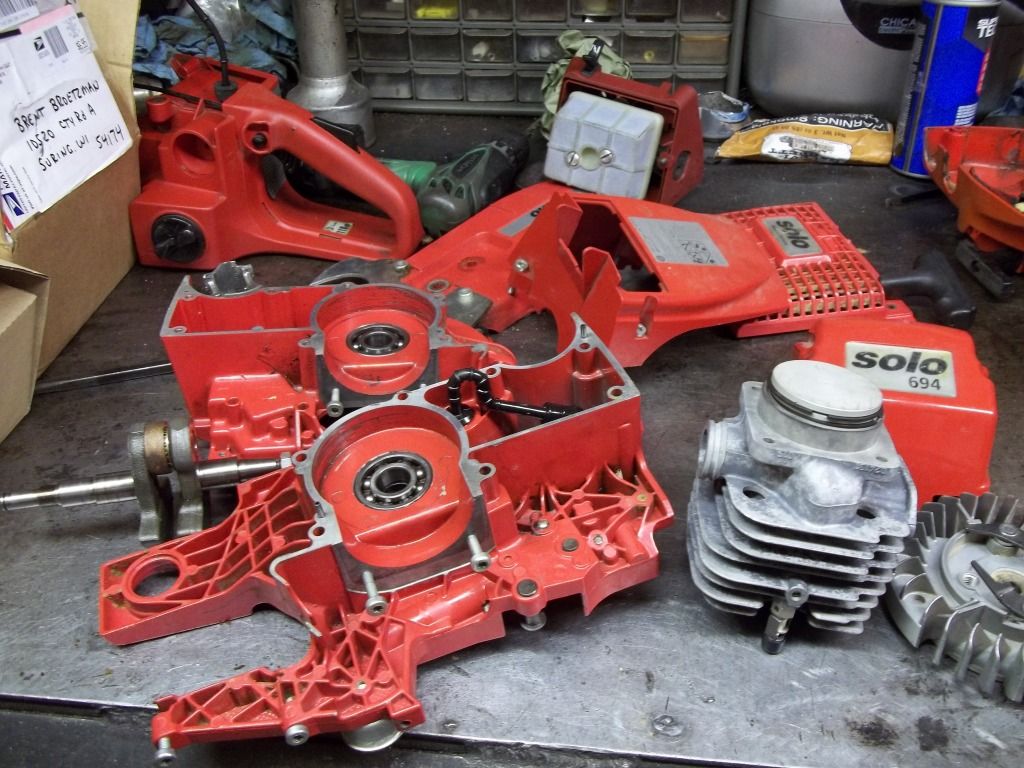

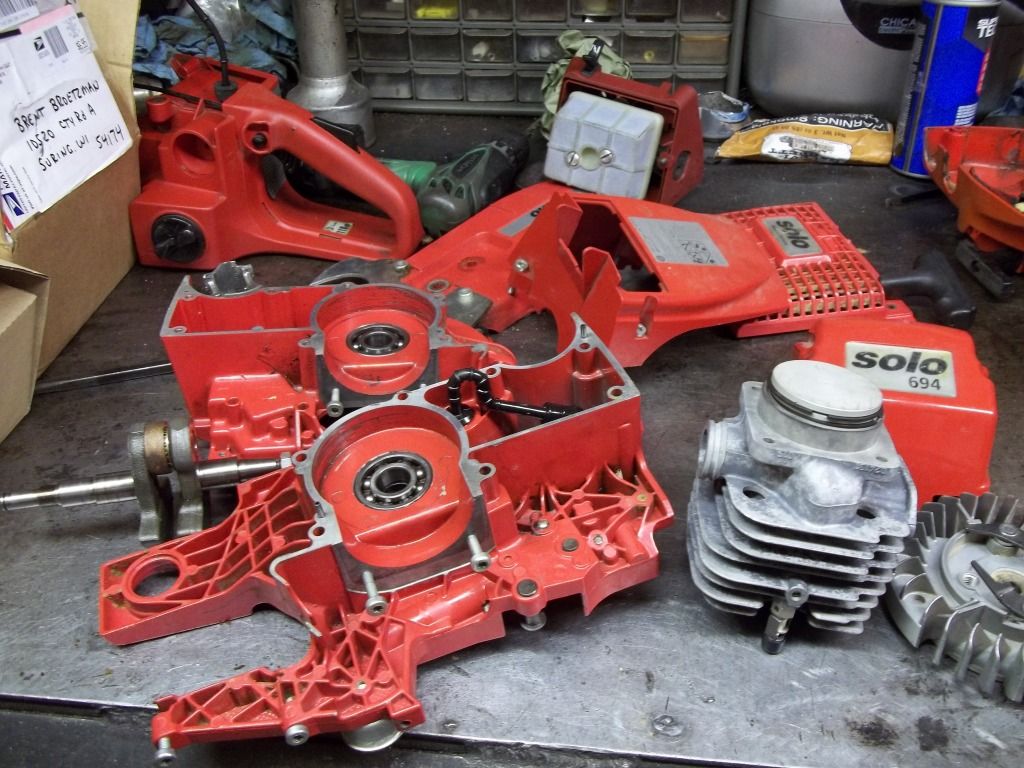

This is how I received the saw. In a box torn apart. This should get me over being spoiled with the new saws I've been building lately.

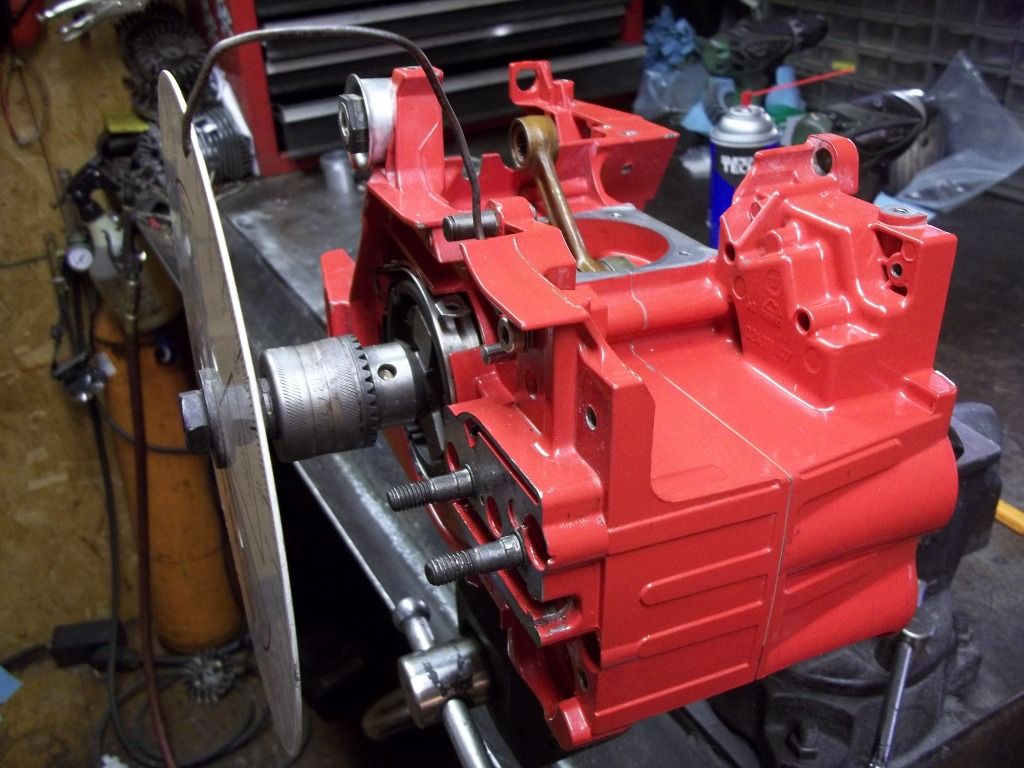

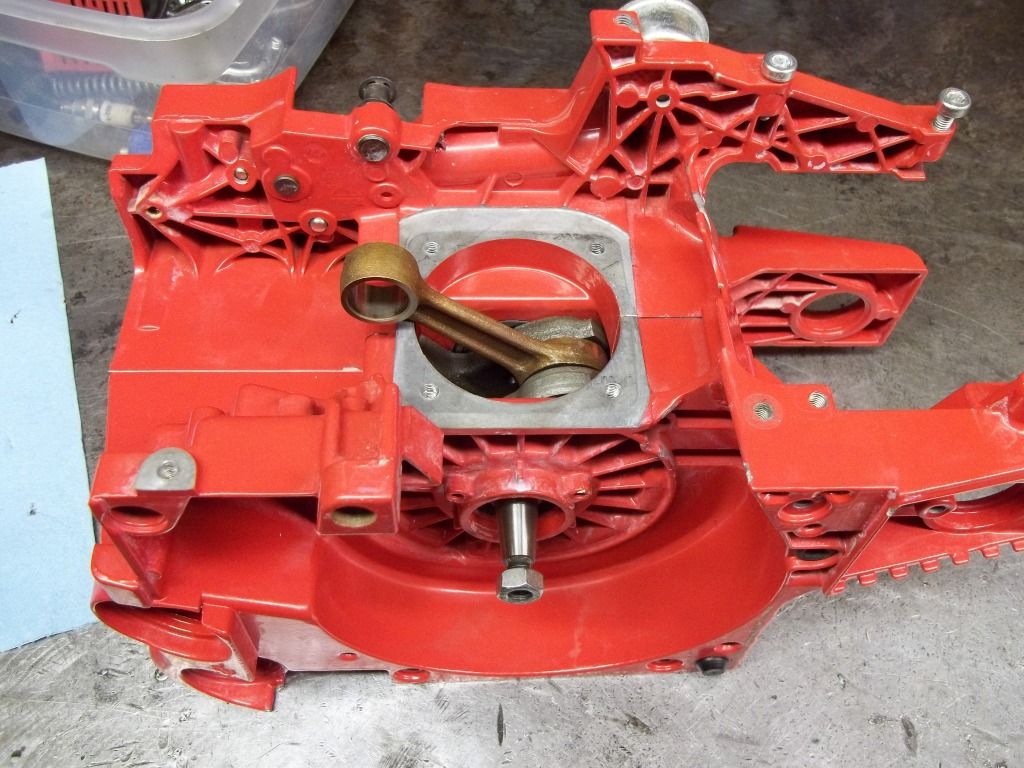

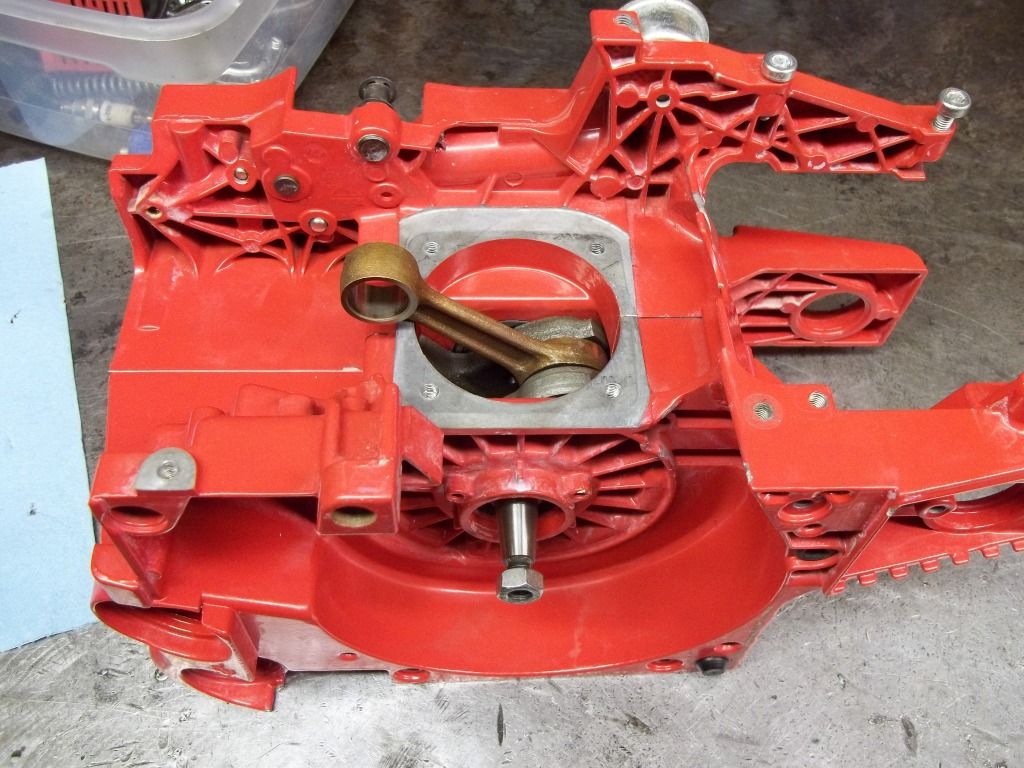

Here's the lower end ready for re assembly.

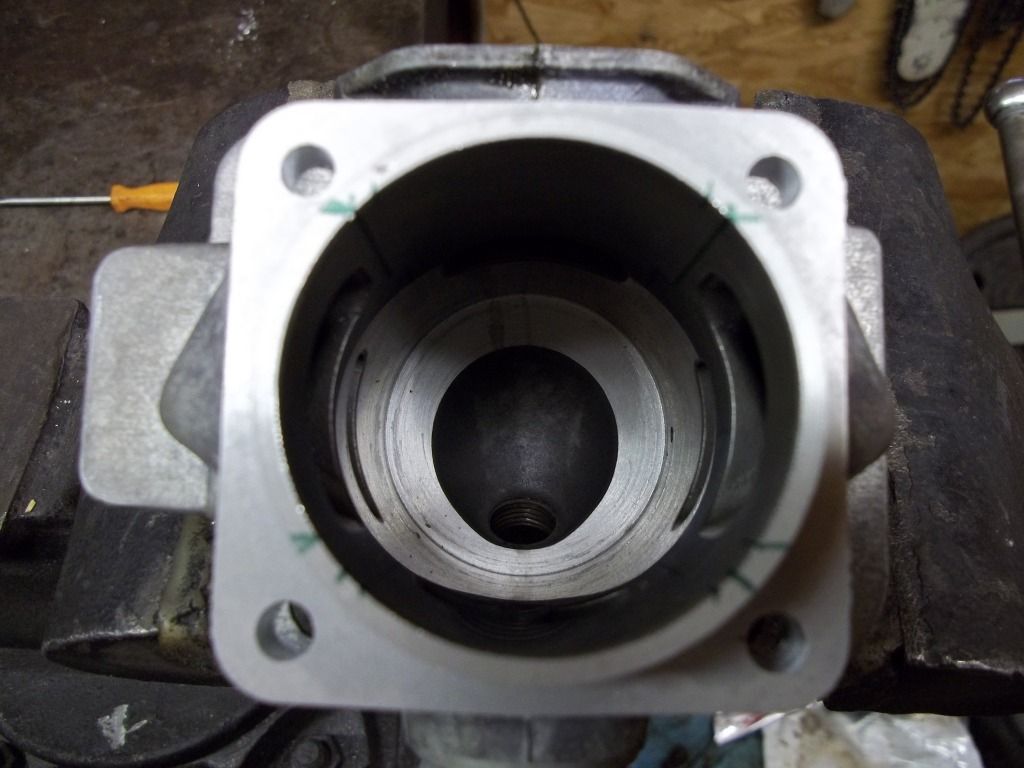

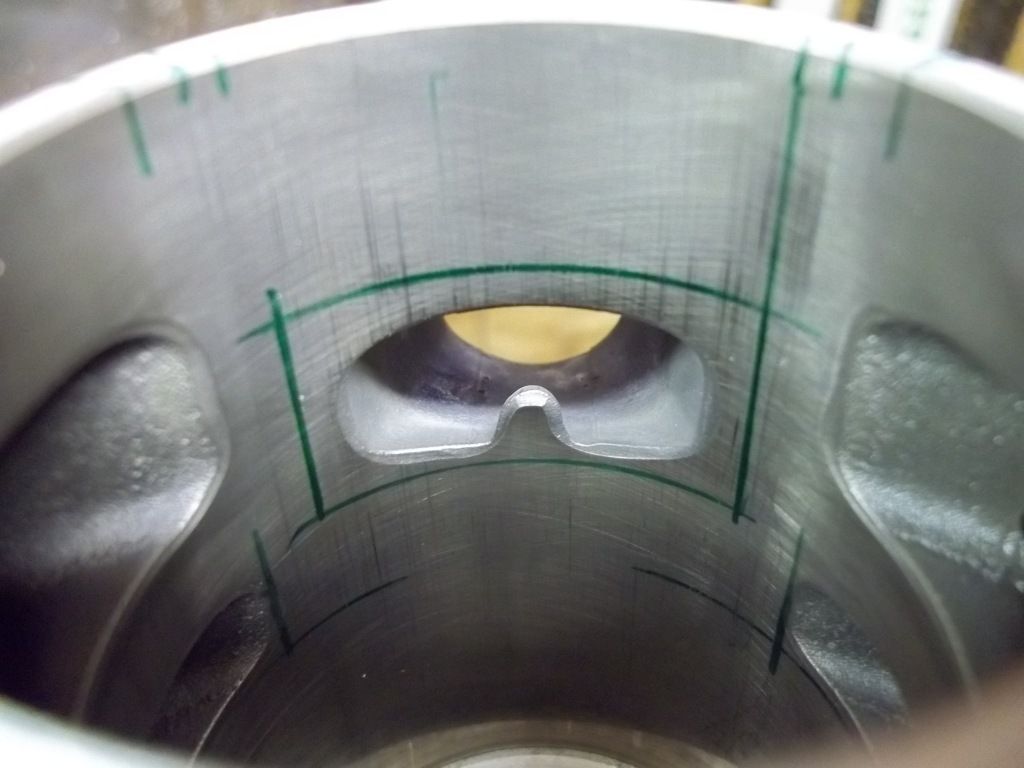

This was the easy part.

Here's the oiler ready to go back together with some new guts.

I decided to put the saw together & run it stock to get a vid for comparison.

[video=youtube_share;nIzOsTrKTBk]http://youtu.be/nIzOsTrKTBk[/video]

This is how I received the saw. In a box torn apart. This should get me over being spoiled with the new saws I've been building lately.

Here's the lower end ready for re assembly.

This was the easy part.

Here's the oiler ready to go back together with some new guts.

I decided to put the saw together & run it stock to get a vid for comparison.

[video=youtube_share;nIzOsTrKTBk]http://youtu.be/nIzOsTrKTBk[/video]