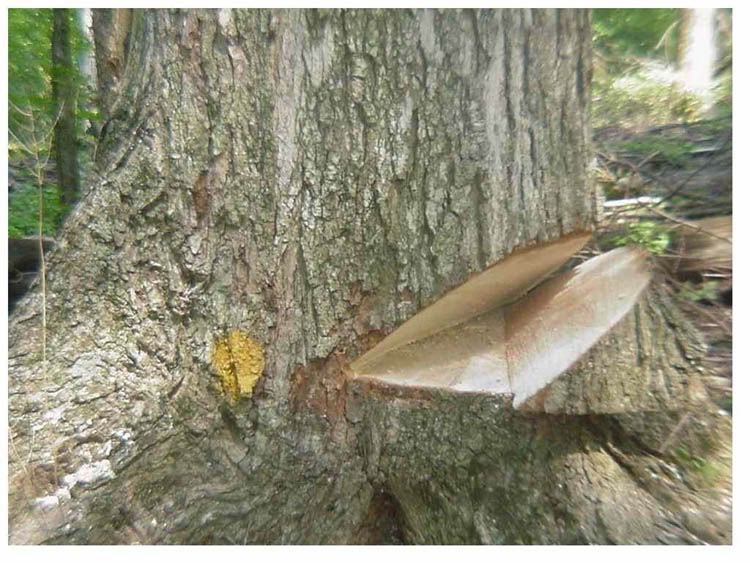

The tapered hinge works. From the forward force of the tree pulling the same; all hinges will fold forward at the same strength.......on that axis. The tapered hinge works on sideleans better than a standard/generic/strip hinge because the tapered reapportions the alloted hinge strength from the forward pull, to a pattern more leveraged against the sidelean pull axis. It does this by reapportioning the fibre pattern to:

A) Providing more fibers in the tension/support/controlling positions, then increasing their powers by-

B) Place fibers in a farther away/ more leveraged by distance of these positions

C) Also, places these greater numbers of tension/support fibers, that have greater leveraged length from the pivot of compressed fiber area, into also a much better leveraged angle.

So, i calculate the support as the length of tension fibers to pivot X the angle of those fibers to pivot/CG line X and the amount of fiber pull in that position, and try to maximize each multiplier. Just as the tree load is calculated as : Length from CG to pivot of compressed fiber X the angle of that weight to the pivot X the amount of that weight. The hinge leverage as support, vs. the tree leverage as load. As long as support= load; the equal and opposites are satiated and in balance, motion only when the load exceeds the support, and the load must seek out it's equal and opposite force of support, so wanders until it can rest against something again. Line pull/ wedge push is fine; but in good wood should be in the direction of the fall, to take advantage of these multipliers. Whereby, the fiber count is set by the forward pressure, so we increase that, then have more fibers, in more leverage-able positions. In wood of less elasticity and constitution, i might angle the direction of push/pull to fight the sidelean more directly myself, but this does unload the hinge of these forces i replace, and thereby the hinges multiplying capabilities.

i learned this from a 4th generation logger's book as listed in Dent on Hinging . So, once again, don't have anything agianst loggers.... Wi as a climber, have taken Dent's theories and turned them sideways; after noticing that the strategies where the same, just varied by direction of the lean force; or other similar pressures as in his bucking scenarios. Once again, going to Gypo crew numbers of times over years to cross compare notes, and distill out the commonalities that ruled in both fields.

Climbers do more felling, than loggers do climbing, and there are lessons at each station; to give broader spectrum to the other. But, a climber, just about always has to stay in the bullpen with the moving beast of a spar, there is no where to go. They are stuck with their decisions. Sometimes catching said load right next to them on a single, stretched thin line, supported by the very architecture they themselves hang from. These lessons are perhaps more intense. These decisions perhaps take an extra second guessing and look to science; as this man's life is literally, more on the line; with nowhere to run if it goes wrong.

So, the math/science is not just about a puzzle of where it goes; but of safety of knowing where it won't go; as well as giving the hinge/face machine more correct mechanics for a larger SWL of the hinge as a controlling device of all this immense leveraged force.

i think the next frontier is to investigate the topic that Dent opens in his felling bible, of closing 1 the lean side of face early. This 'swing dutchy' especially helpful in climbing, where we don't necessarily see the immense weight of a whole tree (though, some cuts come close) ; but in horizontal spars, swept to the side and not down, see higher leveraged angles, and try to move the spar on the hinge a wider radius too. Taking down as the sidelean to across movement, the fat part of tapered on top pulls up, as the close kerf at the base of the hinge pushes up in aid. i think that closing 1 side of face early lends more of a powerful tourqued, rather than linear force input to the scenario of control.

A) Providing more fibers in the tension/support/controlling positions, then increasing their powers by-

B) Place fibers in a farther away/ more leveraged by distance of these positions

C) Also, places these greater numbers of tension/support fibers, that have greater leveraged length from the pivot of compressed fiber area, into also a much better leveraged angle.

So, i calculate the support as the length of tension fibers to pivot X the angle of those fibers to pivot/CG line X and the amount of fiber pull in that position, and try to maximize each multiplier. Just as the tree load is calculated as : Length from CG to pivot of compressed fiber X the angle of that weight to the pivot X the amount of that weight. The hinge leverage as support, vs. the tree leverage as load. As long as support= load; the equal and opposites are satiated and in balance, motion only when the load exceeds the support, and the load must seek out it's equal and opposite force of support, so wanders until it can rest against something again. Line pull/ wedge push is fine; but in good wood should be in the direction of the fall, to take advantage of these multipliers. Whereby, the fiber count is set by the forward pressure, so we increase that, then have more fibers, in more leverage-able positions. In wood of less elasticity and constitution, i might angle the direction of push/pull to fight the sidelean more directly myself, but this does unload the hinge of these forces i replace, and thereby the hinges multiplying capabilities.

i learned this from a 4th generation logger's book as listed in Dent on Hinging . So, once again, don't have anything agianst loggers.... Wi as a climber, have taken Dent's theories and turned them sideways; after noticing that the strategies where the same, just varied by direction of the lean force; or other similar pressures as in his bucking scenarios. Once again, going to Gypo crew numbers of times over years to cross compare notes, and distill out the commonalities that ruled in both fields.

Climbers do more felling, than loggers do climbing, and there are lessons at each station; to give broader spectrum to the other. But, a climber, just about always has to stay in the bullpen with the moving beast of a spar, there is no where to go. They are stuck with their decisions. Sometimes catching said load right next to them on a single, stretched thin line, supported by the very architecture they themselves hang from. These lessons are perhaps more intense. These decisions perhaps take an extra second guessing and look to science; as this man's life is literally, more on the line; with nowhere to run if it goes wrong.

So, the math/science is not just about a puzzle of where it goes; but of safety of knowing where it won't go; as well as giving the hinge/face machine more correct mechanics for a larger SWL of the hinge as a controlling device of all this immense leveraged force.

i think the next frontier is to investigate the topic that Dent opens in his felling bible, of closing 1 the lean side of face early. This 'swing dutchy' especially helpful in climbing, where we don't necessarily see the immense weight of a whole tree (though, some cuts come close) ; but in horizontal spars, swept to the side and not down, see higher leveraged angles, and try to move the spar on the hinge a wider radius too. Taking down as the sidelean to across movement, the fat part of tapered on top pulls up, as the close kerf at the base of the hinge pushes up in aid. i think that closing 1 side of face early lends more of a powerful tourqued, rather than linear force input to the scenario of control.