Dusty dingo

ArboristSite Lurker

Hello,

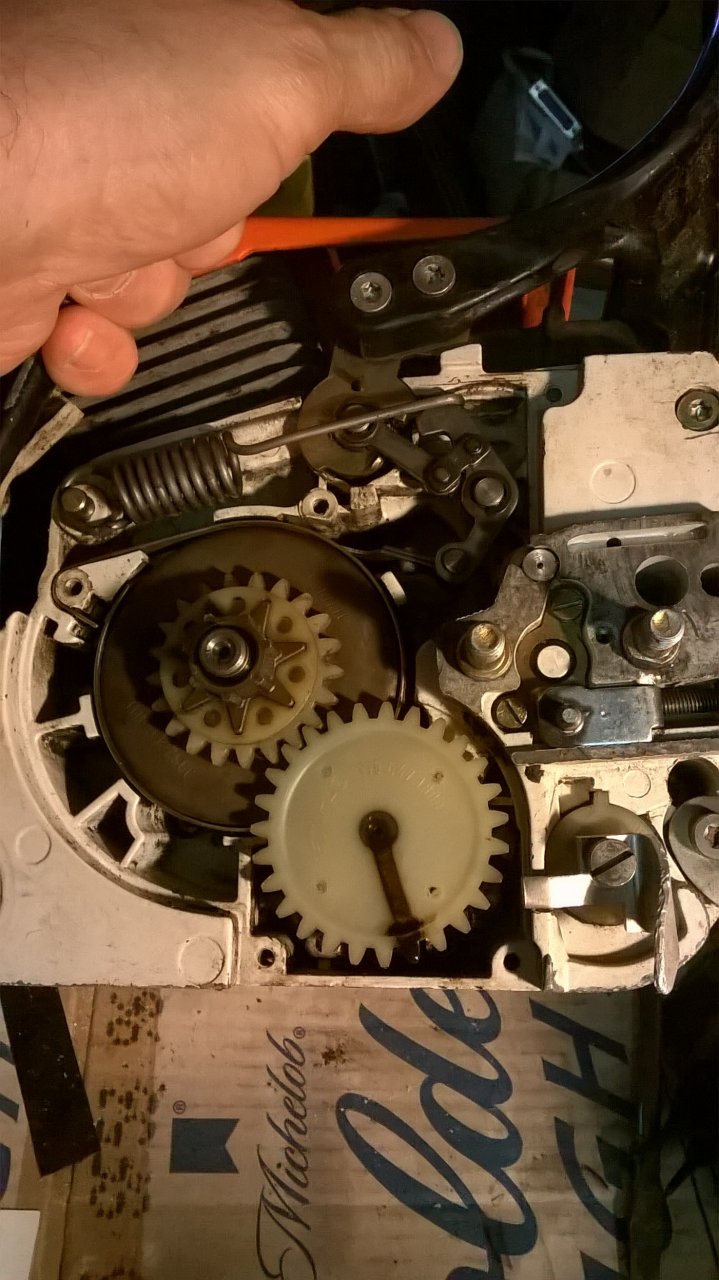

I have a couple of 028's (bought one new in '81 but it got stolen a while ago) and on one, the AV WB with brake, I have a messy black oil being thrown around inside the brake/oil pump cover. It then seeps out the bottom as well, coming around the clutch drive gear cover (round metal plate around the pto shaft hole). It's not nice clean chain oil! It's really black and messy. I am attaching a pic of the cover and where the oil appears to be escaping (?). The hole in the center of that gear appears to only go a little ways, and is only about the size of a small paper clip. Does this gear just slide on to the shaft below, or a friction fit? Or is it put on with more force than that? Will they separate without damage (the gear and shaft to the pump)?

The pump gear doesn't want to pull out more than about 1/4", with turning and pulling moderately,

not forcing it. It turns very easily, also the oil is delivering to the chain bar ok.

It's just the mess I want to fix!

I can't pull anything further to see behind it all with the pump gear not pulling out to get to the screws.

There is BLACK oil (not nice clean bar oil as it is on the bar oiling hole)coming out from the tiny center hole in the pump gear shaft (see pic with the oil streak coming down the side of gear). You can pull the gear out a bit and push it in a bit, and the oil seems to be coming from the little 'pumping' back and forth like that, however, it also comes out when you run the saw with clutch turning, just seeps out a little at a time, but obviously ads up a lot to make the mess!

I did a major choke cleaner and air cleanout of the housing behind and around the clutch, brake and oil

pump area!

I don't think this is normal! My other 028 has no brake, and also stays dry in that area.

Can you give me some thoughts on the above issues, and what I can do to make it right?

Last, I am needing to know if there is an oil pump overhaul kit, with seals and hoses? I don't find it anywhere if there is.

I hope this posting displays properly! We shall see

Thanks for your time and advice!

Dusty

I have a couple of 028's (bought one new in '81 but it got stolen a while ago) and on one, the AV WB with brake, I have a messy black oil being thrown around inside the brake/oil pump cover. It then seeps out the bottom as well, coming around the clutch drive gear cover (round metal plate around the pto shaft hole). It's not nice clean chain oil! It's really black and messy. I am attaching a pic of the cover and where the oil appears to be escaping (?). The hole in the center of that gear appears to only go a little ways, and is only about the size of a small paper clip. Does this gear just slide on to the shaft below, or a friction fit? Or is it put on with more force than that? Will they separate without damage (the gear and shaft to the pump)?

The pump gear doesn't want to pull out more than about 1/4", with turning and pulling moderately,

not forcing it. It turns very easily, also the oil is delivering to the chain bar ok.

It's just the mess I want to fix!

I can't pull anything further to see behind it all with the pump gear not pulling out to get to the screws.

There is BLACK oil (not nice clean bar oil as it is on the bar oiling hole)coming out from the tiny center hole in the pump gear shaft (see pic with the oil streak coming down the side of gear). You can pull the gear out a bit and push it in a bit, and the oil seems to be coming from the little 'pumping' back and forth like that, however, it also comes out when you run the saw with clutch turning, just seeps out a little at a time, but obviously ads up a lot to make the mess!

I did a major choke cleaner and air cleanout of the housing behind and around the clutch, brake and oil

pump area!

I don't think this is normal! My other 028 has no brake, and also stays dry in that area.

Can you give me some thoughts on the above issues, and what I can do to make it right?

Last, I am needing to know if there is an oil pump overhaul kit, with seals and hoses? I don't find it anywhere if there is.

I hope this posting displays properly! We shall see

Thanks for your time and advice!

Dusty

, for a large spray bottle. You can get refills in maybe a 24 oz or larger, for same price!! I love that stuff for around the shop, even works around the kitchen stove area, so easy to clean up after it with a hot wet rag or just rinse it off. It will take a chain saw exterior from greasy fingerprinted and grime to squeaky clean. I use a soft brush on the outside after spraying it down, or a parts brush inside to get a bit more agressive.

, for a large spray bottle. You can get refills in maybe a 24 oz or larger, for same price!! I love that stuff for around the shop, even works around the kitchen stove area, so easy to clean up after it with a hot wet rag or just rinse it off. It will take a chain saw exterior from greasy fingerprinted and grime to squeaky clean. I use a soft brush on the outside after spraying it down, or a parts brush inside to get a bit more agressive.