JoPy

ArboristSite Lurker

Hi fellas,

I have this old Wood Boss I inherited from my wifes grandfather. It used to be a stubborn starting saw, but I replaced the fuel filter, spark plug, and air filter a couple weeks ago and it has been kicking on second pull regularly. So this afternoon I was cutting up firewood and the blade was nice and sharp, spitting out chips like it should when I got to this really knotty crotch section and regretfully decided to go after it. The blade dulled up by halfway through and I kept going. The saw was running hot and I figured both it and I needed a break so I cooled it down for a few minutes and went back to it and the saw stalled.

It was running for about 5-10 seconds per start for a few starts. I figured I would try it again after a long cool down and now I cant get it to start at all... Where do I begin? Thanks for the help!

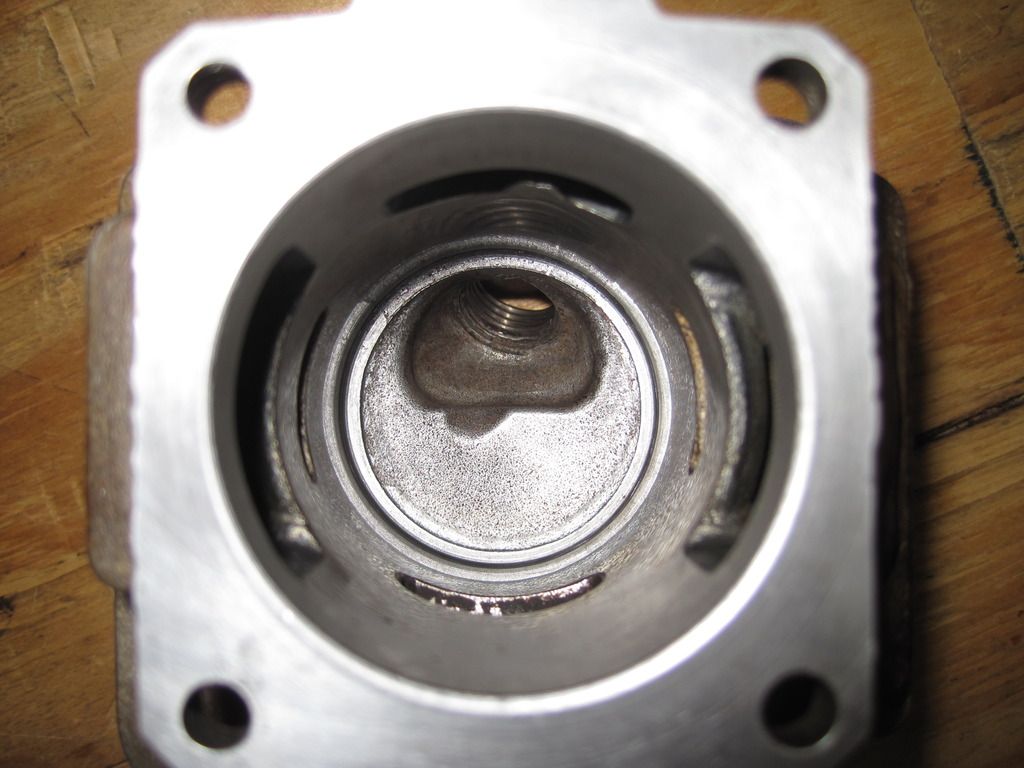

Rings

Top of Cylinder

I have this old Wood Boss I inherited from my wifes grandfather. It used to be a stubborn starting saw, but I replaced the fuel filter, spark plug, and air filter a couple weeks ago and it has been kicking on second pull regularly. So this afternoon I was cutting up firewood and the blade was nice and sharp, spitting out chips like it should when I got to this really knotty crotch section and regretfully decided to go after it. The blade dulled up by halfway through and I kept going. The saw was running hot and I figured both it and I needed a break so I cooled it down for a few minutes and went back to it and the saw stalled.

It was running for about 5-10 seconds per start for a few starts. I figured I would try it again after a long cool down and now I cant get it to start at all... Where do I begin? Thanks for the help!

Rings

Top of Cylinder