Rookie1

Addicted to ArboristSite

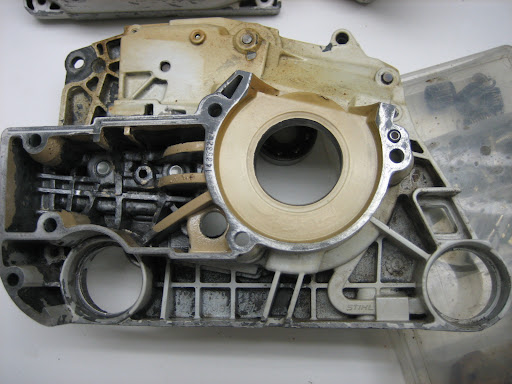

Nice pics of the 044 your working on, I like how you organize parts. I also like 028 pics too.

Nice pics of the 044 your working on, I like how you organize parts. I also like 028 pics too.

Have you comapred the porting of the older style (right) than the cylinder on the left? They both work, but the transfers are interestingly different.

I had some cutaway cylinders in a post a couple of years back, and I lined up both halves of the two different cylinders for comparision.

maybe someone can find them with search?

Enter your email address to join: