Im not convinced easily that this AT technology is all that ready for the masses. More than enough threads to the contrary. This group here is likely but a small sampling of actual real world users, so problem rates may actually be much higher. Coupled with expensive diagnostic equipment, or lack of available diagnostic equipment, untrained or inexperienced dealers and you have a recipe for unhappy customers. A guy with a $700 saw thats hard to warm start still aint going to be happy regardless. It may well be the future but for now im glad the adjustable carb still exists. Im not worried about saving a pinch of fuel, or running at the most optimum rpm, more about getting some wood to the stove is whats important to me. Standing in the repair line at the Husky dealer, not so much. Just my thoughts.

plenty AT in use regular in the woods with no problems whatsoever, and plenty of users not ready for any change. Not bashing, mind you, but since i like real world experience, and hearing some of that firsthand here on AS i will share. Nevermind you did not ask- my apologies. I own two AT saws and like many was resistant to the change, but looking how smart lmbrkid is with technology and her interest in saws sparked my interest in change and growth. Neither saw has started for other people. Let me repeat, neither saw has started for otheres. I never had a problem, as i understand the switch function. I have no doubt there are some actual problems, but to a large degree, the masses on here are not pro users, or at least the thread are not representative of that- i mean, how many hundred pages exist about how to use different sharpening rigs, or what oil to use. I realise some laugh at these threads, but many soak it in best they can, and work hard to understand chain sharpening and mixing fuel&oil.

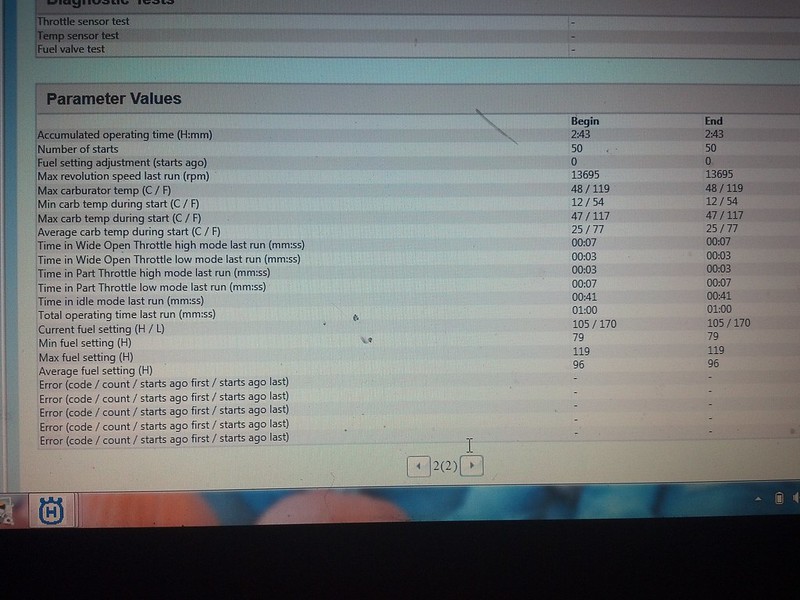

My dealer had sold over five dozen AT last time i checked in, which was months ago. He indicated no charge to hook up my saw, and if there ever is a problem he cant fix, he will give me a new saw. Is it true? Who knows, but i sure as heck will report here if i have to test his word. Some great people here on AS have offerred to read the saw no charge also. Hats off to those of you :msp_thumbup: The diagnostic tool might be expensive now, but that is temporary. If it stays too expensive they will be sorry as another manufacturer will pounce. Rememberall the bit#### about OBD and how expensive it would be? Now you can buy one for 1/4 the cost of a tank of fuel, and print out the instructions and parts list for a repair, or go to a parts house, they do it for free hoping to sell the parts.

My 550 uses half the fuel of my ported 346. Half adds up quick at $5/gallon fuelmix to a guy who uses his saw any amount. Not long and the cost of the saw is covered. Cost of the 550xp shoud be one side or the other of $500. I just ordered one with heat for a shade over $500.

I say some refuse change and will be left behind.

-rant over, at least for now. My apologies if it seems personal, it is intended as discussion. There is some great discussion and info in this thread, which is why i am here