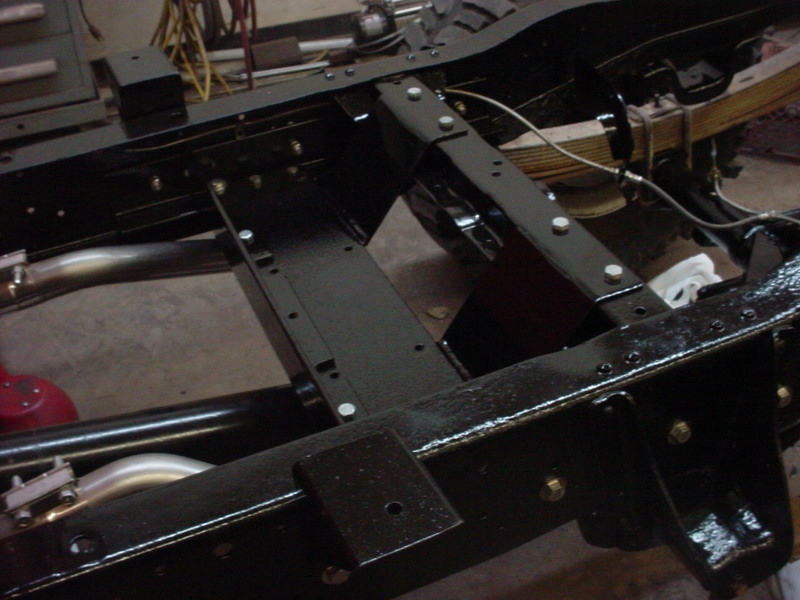

With this done I'll work on putting the aluminum wall in.

With the bracing there was no way to get it in with 1 or 2 pieces. Ended up having to make 6 pieces. I'm using 3/16" aluminum sheet.

I'm cutting this freehand with a cut off wheel and angle grinder.

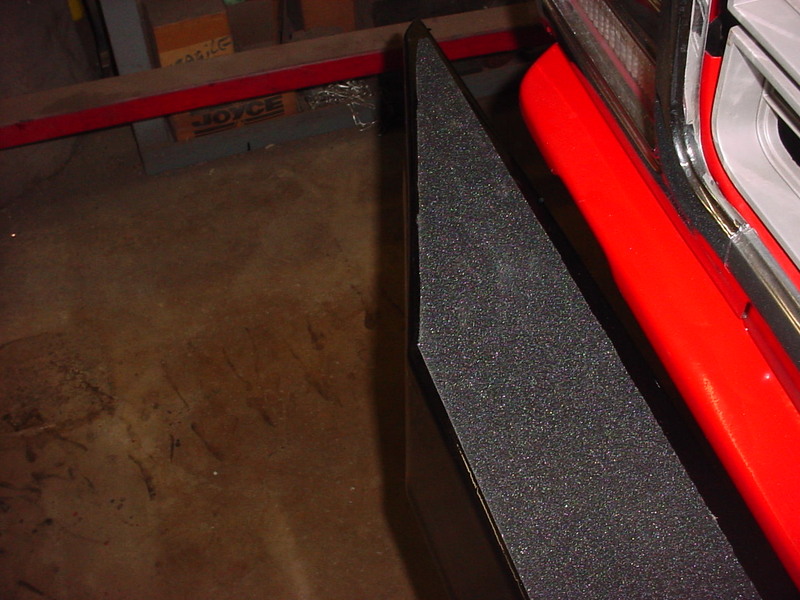

Wall is in and now working on enclosing the backside for some out of the weather/eyesight storage. Cut some OSB so it self locks for a floor.

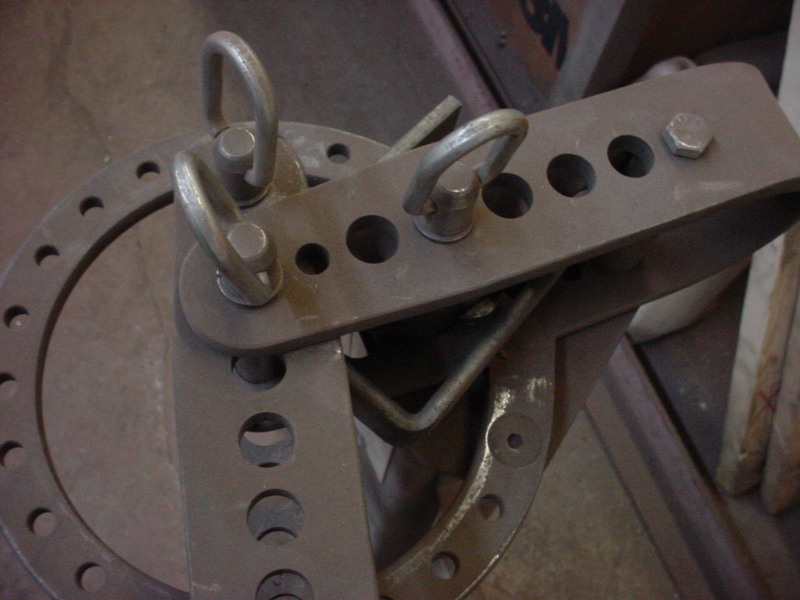

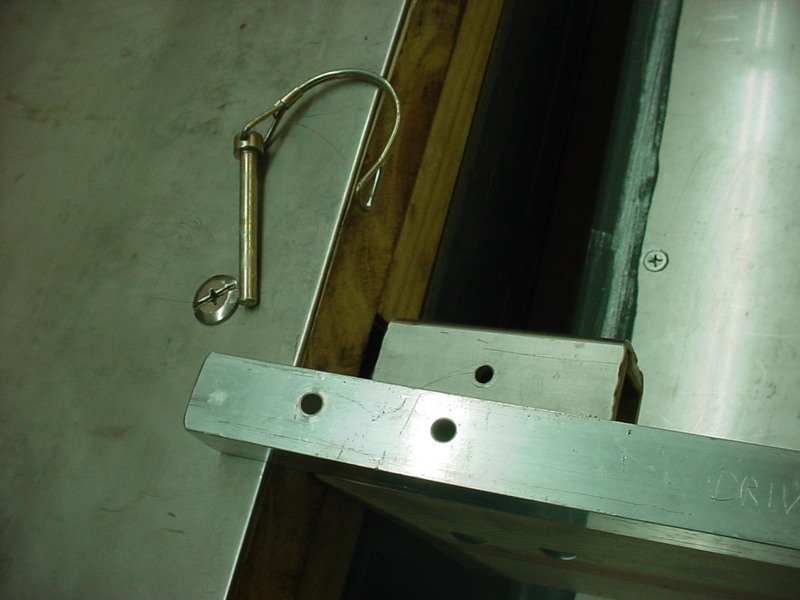

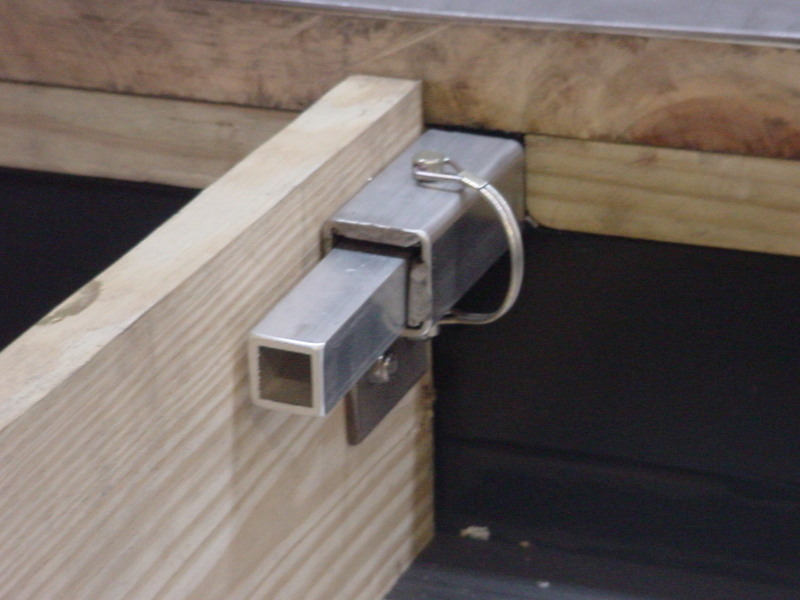

Cut some panels so they slide inside the back supports. The bolts for the upright wall and future back panel will keep them from sliding in.

They will just lean out and lift up. Simple and secure.

I just welded a small piece on the bottom edge and no way it can get over it when in positio

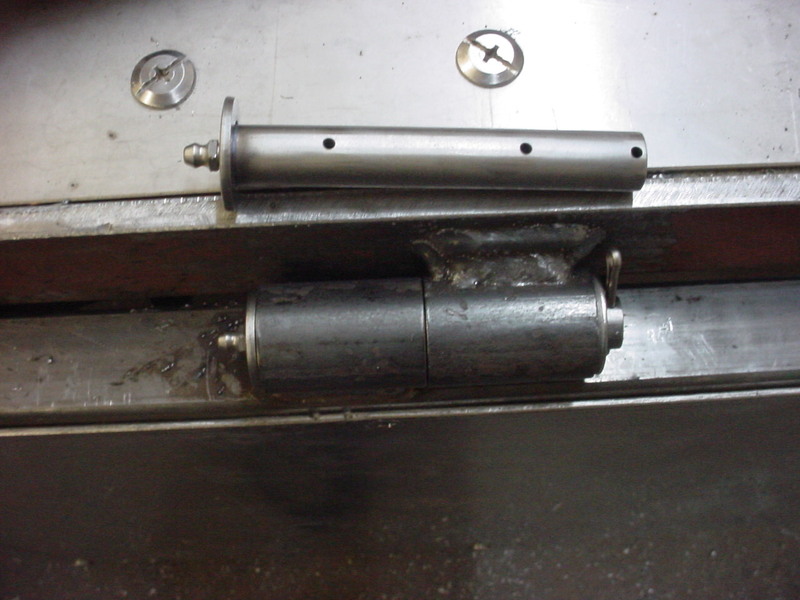

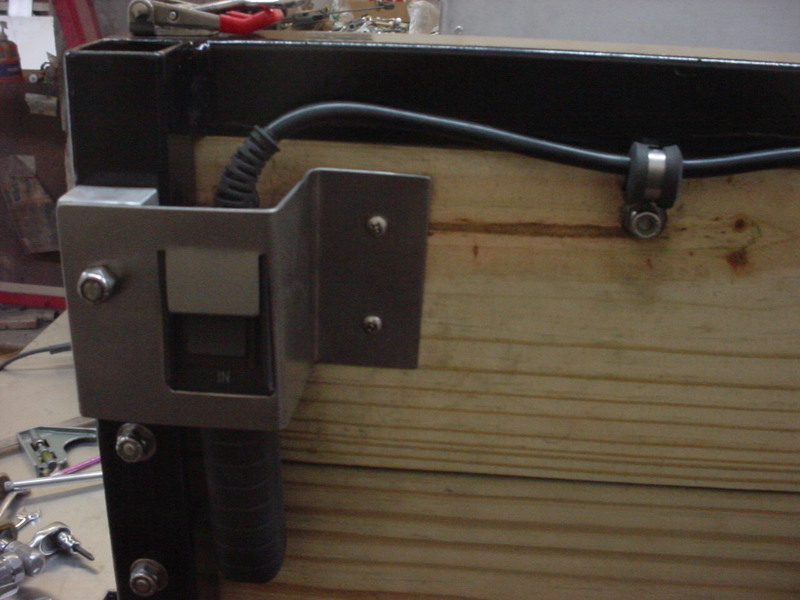

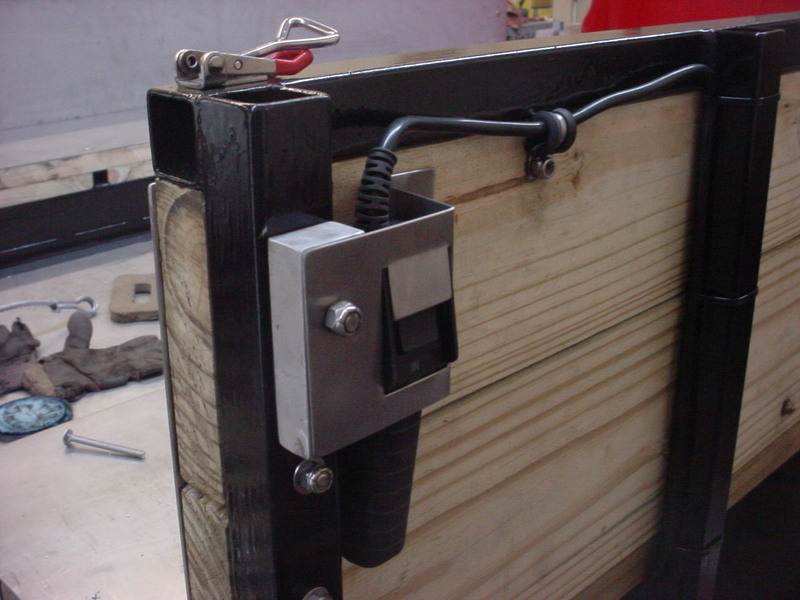

Figured I'd make an easy grab handle and a spring loaded hold down for the access panel. Just drill a hole that was a little bigger than the small piece of pipe I had laying around. Then cut it in half and off.