Jim Timber

1/4 bubble off

I've been using my "scrap bin" trailer well beyond it's intended capacity for most of it's time in service. On the rare occasion it gets to do things like haul a 250# buddy, or if it's really lucky just hold my saws and oil; the rest of the time it's piled high with wood. I call it the scrap bin trailer for the simple fact that other than the wheels, the whole thing came out of my drops from other projects, or stuff that I'd picked up free. When I decided to camo paint it, that actually raised the cost 20% because I didn't have brown or green paint.

The 10" wheels actually work remarkably well over large obstacles. There's been some logs where they've gone end over, but 95% of the time they just ride up the object and keep on truck'n. That's why I decided not to make a spinning axle on the walking beams for this trailer. If I ever manage to get it stuck, I just need to put a smaller log down to get it to climb, so there's really nothing to worry about. It's been a good trailer, and will likely continue to be used, but hopefully not over worked like it's been.

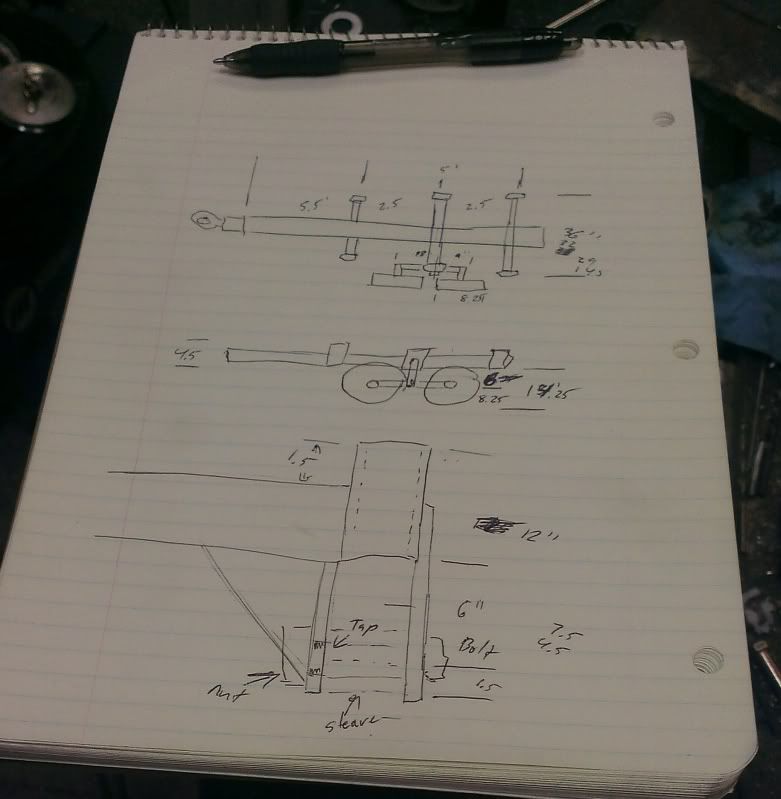

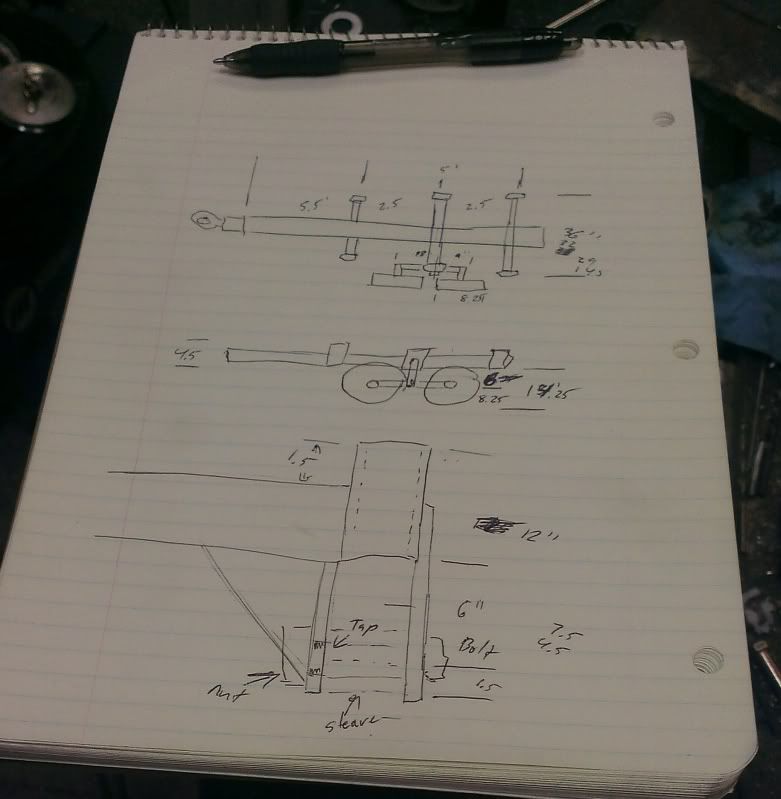

Here's a rare glimpse into how I operate when I use technology in design. That's a state of the art ball point pen. I might be a machinist, but I don't like working in CAD. I just work faster on paper when it's something only I need to understand. I've already made a couple changes from this sketch, but since it's not critical to other dimensions there was no reason to update the drawing. You'll be able to see them vividly once things start taking shape.

I might be a machinist, but I don't like working in CAD. I just work faster on paper when it's something only I need to understand. I've already made a couple changes from this sketch, but since it's not critical to other dimensions there was no reason to update the drawing. You'll be able to see them vividly once things start taking shape.

This is going to be a multi-purpose trailer similar to the T-rex (only not made in china), but a little different too. There'll be a wooden flatbed deck on the frame, and stake pockets for 2x4's. I'll have provisions for a dump box as well, but that'll be a winter project for later on. I also plan on making a people hauling "bench" for it as well. When it's cold and dark, it's a lot nicer to get picked up from the deer stand than have to walk half a mile back to the cabin. Deer don't get as spooked by me rolling the woods on the wheeler as they do seeing people walking, so that's an added benefit.

So now I start making parts:

Even with the extraneous crap on my fab table, this is a drastic improvement to the mess it was yesterday. I had receipts from back before the dictator was elected buried in the mess.

I had receipts from back before the dictator was elected buried in the mess.

I still need to procure axles and hubs, and should have those tonight.

Back to cutting steel...

The 10" wheels actually work remarkably well over large obstacles. There's been some logs where they've gone end over, but 95% of the time they just ride up the object and keep on truck'n. That's why I decided not to make a spinning axle on the walking beams for this trailer. If I ever manage to get it stuck, I just need to put a smaller log down to get it to climb, so there's really nothing to worry about. It's been a good trailer, and will likely continue to be used, but hopefully not over worked like it's been.

Here's a rare glimpse into how I operate when I use technology in design. That's a state of the art ball point pen.

This is going to be a multi-purpose trailer similar to the T-rex (only not made in china), but a little different too. There'll be a wooden flatbed deck on the frame, and stake pockets for 2x4's. I'll have provisions for a dump box as well, but that'll be a winter project for later on. I also plan on making a people hauling "bench" for it as well. When it's cold and dark, it's a lot nicer to get picked up from the deer stand than have to walk half a mile back to the cabin. Deer don't get as spooked by me rolling the woods on the wheeler as they do seeing people walking, so that's an added benefit.

So now I start making parts:

Even with the extraneous crap on my fab table, this is a drastic improvement to the mess it was yesterday.

I had receipts from back before the dictator was elected buried in the mess.

I had receipts from back before the dictator was elected buried in the mess.I still need to procure axles and hubs, and should have those tonight.

Back to cutting steel...

There was a strap on that load when I finished stacking it. It fell off on the bumpy trip.

There was a strap on that load when I finished stacking it. It fell off on the bumpy trip.