FATGUY

Addicted to ArboristSite

- Joined

- Jun 2, 2008

- Messages

- 6,535

- Reaction score

- 1,537

mornin' Gregg, Steve

mornin' Gregg, Steve

I didn't see the what that 505 ended at. But, your right, Mark would have a LOT more than four transactions..LOL What did it sell for?

Gregg,

mornin' Gregg, Steve

A lot of S25Da's. Need to add an S25CVA.

Bob

I found the Timken seal box and it states the seal size as 0.625x.0875x.0125. I believe they show ID first and then OD with the height as .0125.

Bob

yes i want a pristeen green 25da some day and i have been trying for a cva!!!! thought i had one a week ago and the deal some how fell apart still not sure what happened guy was supposed to relist it never did? yes once i get those 2 i will be on the hunt for some bigger ones . if they run like the25sda ones power to weight i mean i will be very happy!:hmm3grin2orange:

Bob: Yah got too many zeros. How about 0.625" x 0.875" x 0.125" ?

The CR number for that size seal is 6120 HMS1.

I'd expect that the actual outside diameter of a new seal to be 0.8755"-0.8765" (MAX!).

0.001" interfearence fit is a lot on a diameter of 0.875"

Yup. an extra zero in the OD and height. Thanks. 6120 HMS1 is from which manuf.? The Timken number is 253747.

Bob

Brad, its my opinion that ths S25Da and S25cva are the most desireable. Both have and manual and auto oiling. The CVA is the anti-vibe version. Both are 2.3 and 38cc(designated by the S). Very well built and very strong for a 38cc saw.Which of the little 25s is the most desireable, and why?

Brad, its my opinion that ths S25Da and S25cva are the most desireable. Both have and manual and auto oiling. The CVA is the anti-vibe version. Both are 2.3 and 38cc(designated by the S). Very well built and very strong for a 38cc saw.

Bob

I didn't see the what that 505 ended at. But, your right, Mark would have a LOT more than four transactions..LOL What did it sell for?

Gregg,

I was surprised how strong the one being given away in the fundraiser thread is. That got my attention. I assume these are reed saws?

Is the 38cc topend a direct replacement on the 33cc saws?

If I am not mistaken I believe the older super 25 saws had a longer stroke but a smaller bore. The newer versions had a shorter stroke, but larger bore. It has been years since I have had them apart that far.

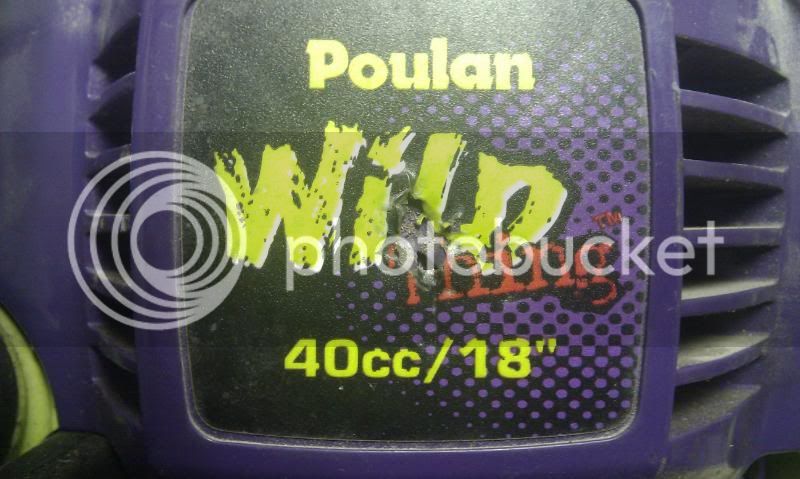

So sad to say really good neighbour behind us is moving away, he is a concrete guy, does all the fancy stamped concrete and such, so anyway he is cleaning out his garage and he ends up giving me a shop vac, then he mentions he has two saws one a wildthing 18" and a Craftsman 14", one seemed alright, though I did not try to start any of them, but he mentions the wildthing was some kind of seized up, they flooded it, so that is why it won't turn, so he figured just take out the spark plug and it should free it up.

Well I brought them home and tonight took the starter cover off and the flywheel turns real nice, so if you can tell by the last picture I believe a very small but heavy gouge in that cover, hmm that is what is holding it back, so now just have to see about trying to knock it back out and saw should be good to go.

Then I can tinker with the 14" one, it should be alright after a clean up and good fuel.

Like he said, he is not a mechanic, and he knew I knew a bit, so am looking forward to making them all run.

Enter your email address to join: