As I recall, my 024AVS used about 3/4 tank of bar oil for every tank of gas when it was new. The last few years, it pumped less and less, to where now it's just a trickle. Thanks to a search of this site, I found information to remove the pump, and clean out everything. This pump looks very different from others that are pictured on the site. It is not adjustable. I can feel a slight vacuum on the inlet when I spin it, and a few drops of oil put in the inlet get pushed through to the outlet, so is the pump working? The pin does not go all the way through the case of this pump, so I see no way to drive it out and disassemble the pump. The worm gear is perfect. The oil hose from the tank is not soft, and filter is clear. There was no debris in the tank. The outlet hose is clear ,and is not cracked. I cleaned the little vent hole with spray carb cleaner, and noted it has a check ball inside. Could that have been hung up shutting down the vent? I noticed in the IPL that there are 3 different pumps shown, a 0.50 mm stroke, a 0.65 mm stroke, and one that is adjustable with "Conversion Kit" PN 1121 007 1043. My pump, pn 1121 647 0400, is not shown. Could I or should I retrofit the adjustable pump to replace mine and how much is that part? Is the AVS pump I have known to be problematic? I can get a 026pro pump reasonable; could I retrofit that using a new worm gear? At this point I am thinking of replacing the tank hose assembly so I am sure there is a good seal between the pump and that hose, and putting it back together. Is there anything else I can do?

Thanks,

Bob

024AVS oil pump

Oil tank hose

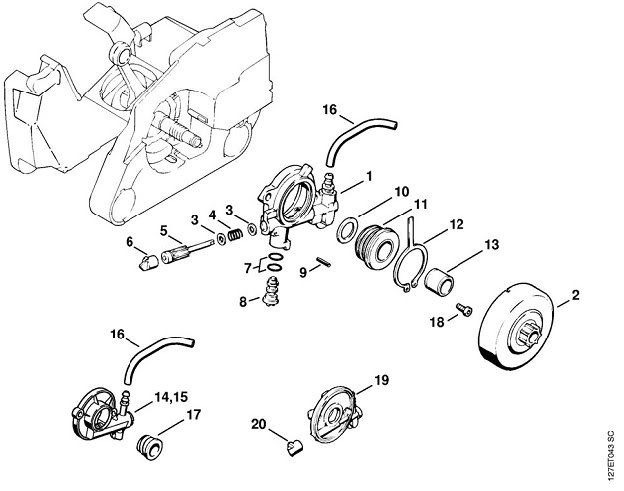

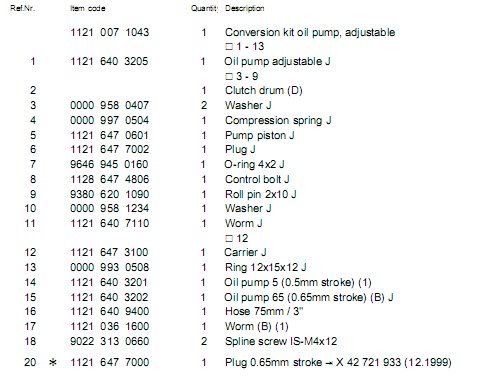

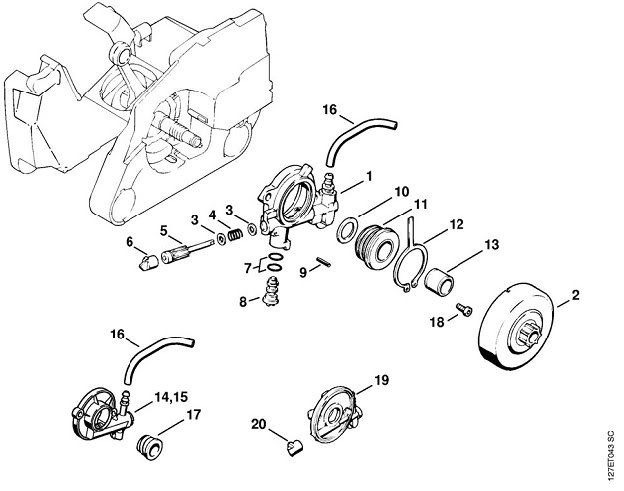

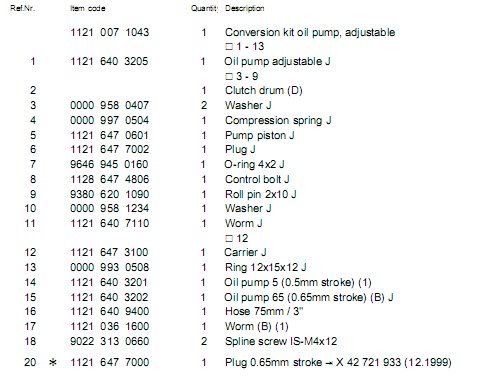

Diagram

Thanks,

Bob

024AVS oil pump

Oil tank hose

Diagram