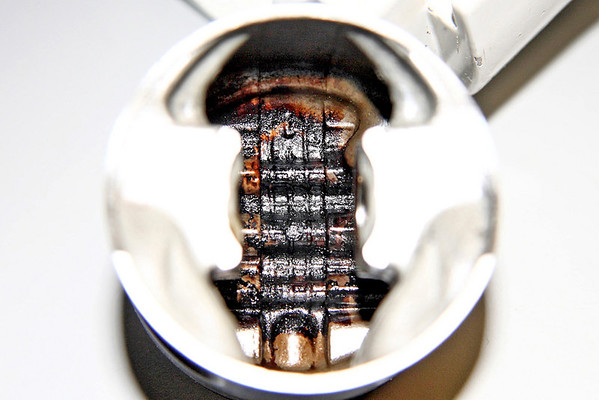

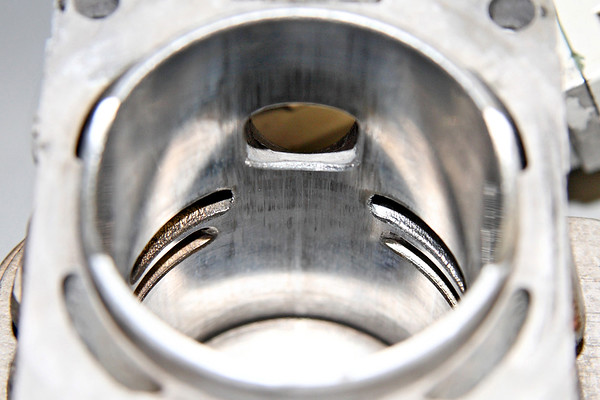

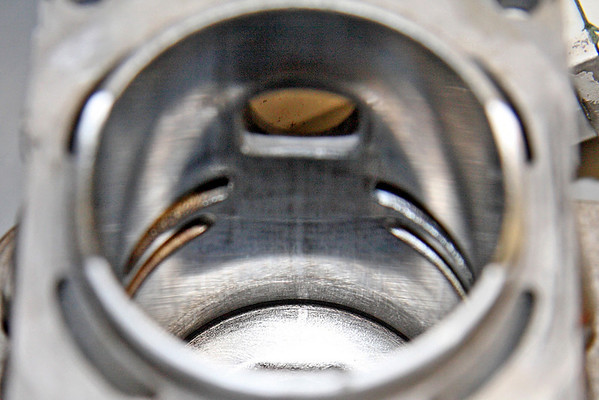

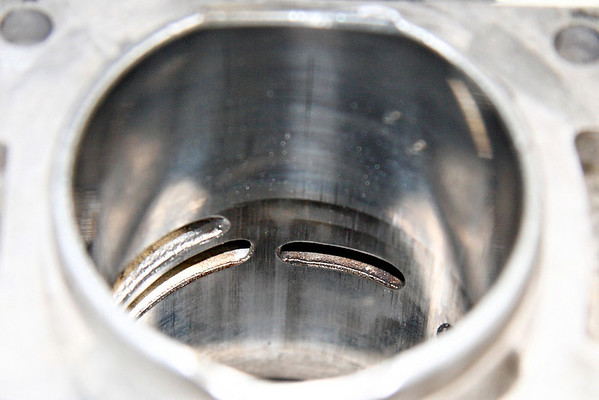

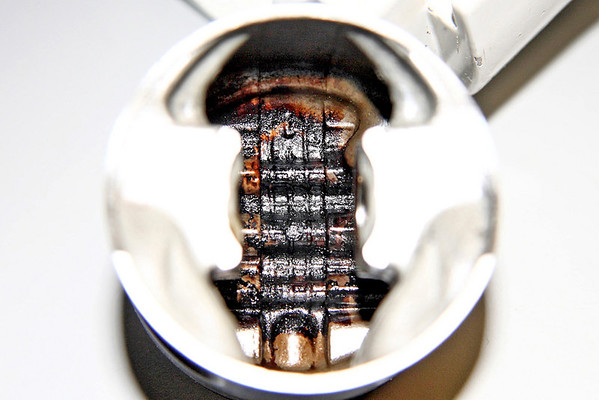

I've got my strong suspicions, but would like to see what you guys think. This P&C is off a good running MS441. Compression cold was about 142 PSI. None of the "marks" in the cylinder can be felt at all. The rings still have the little micro lines in them like new ones.

So two questions here. What caused the marks in the cylinder? What caused all the carbon on the piston?

So two questions here. What caused the marks in the cylinder? What caused all the carbon on the piston?