brncreeper

Addicted to ArboristSite

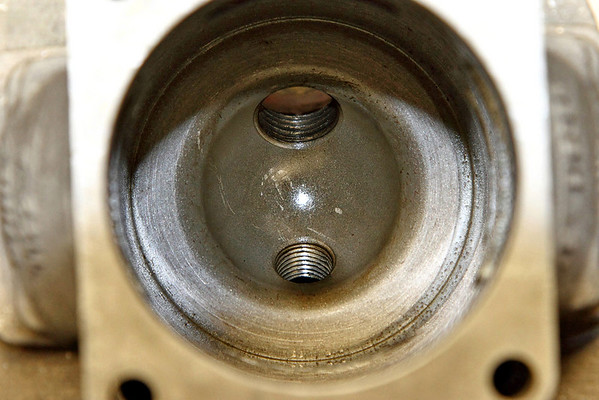

Ms660

I kinda question those pop up set ups as far as reliability. They great in 5 seconds of video, but what about a days work of milling?

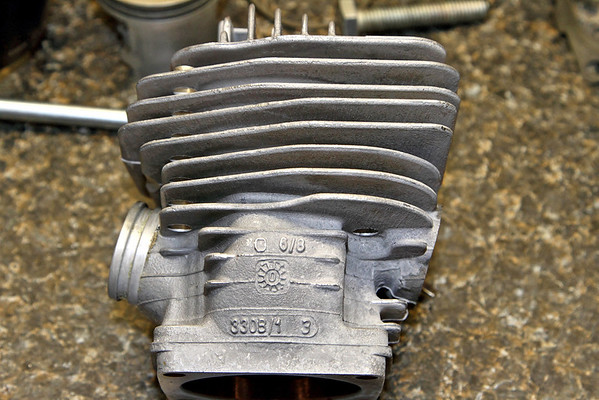

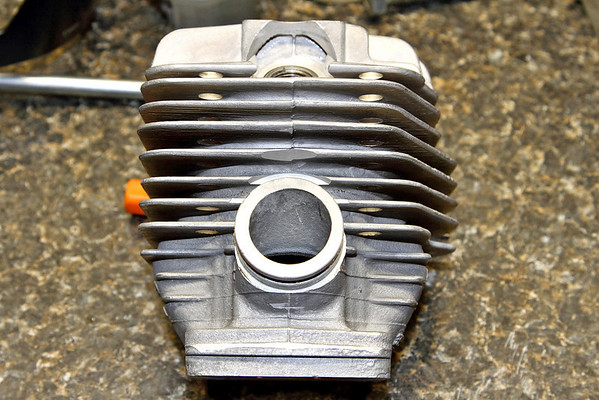

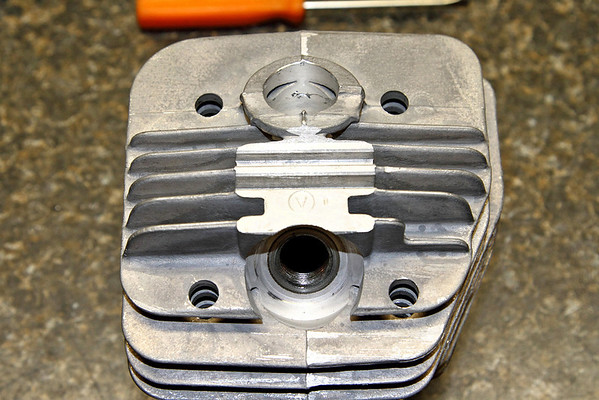

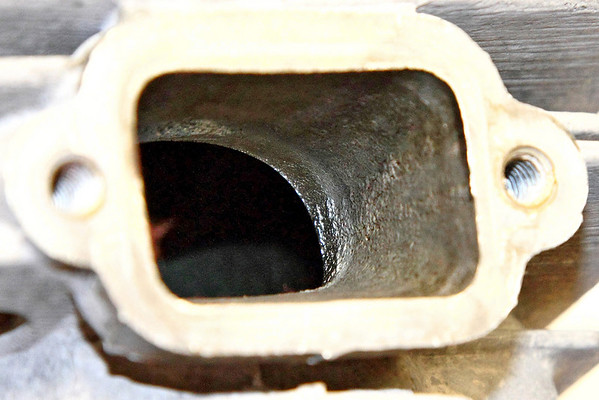

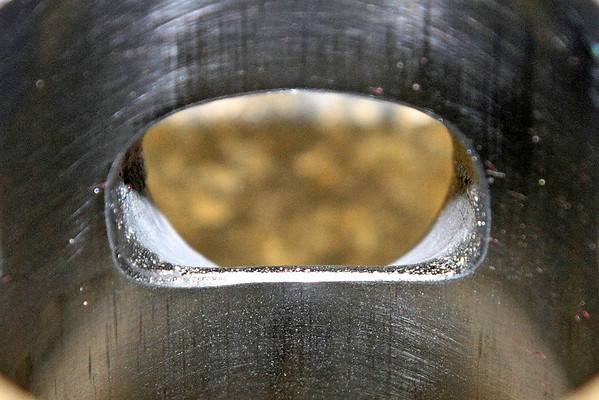

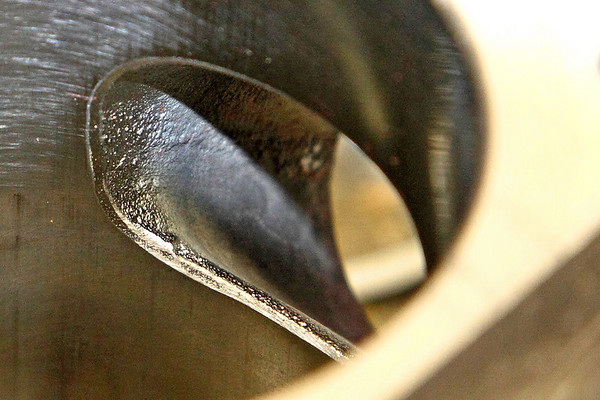

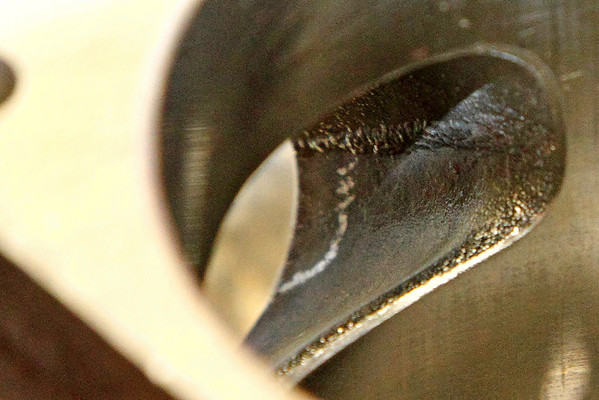

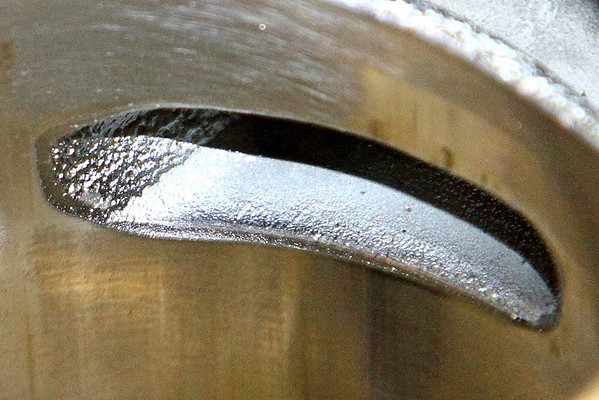

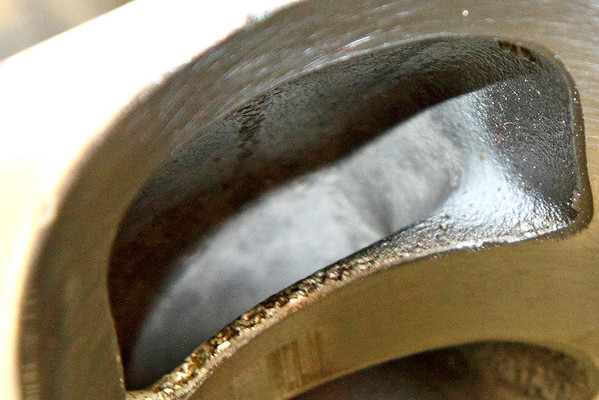

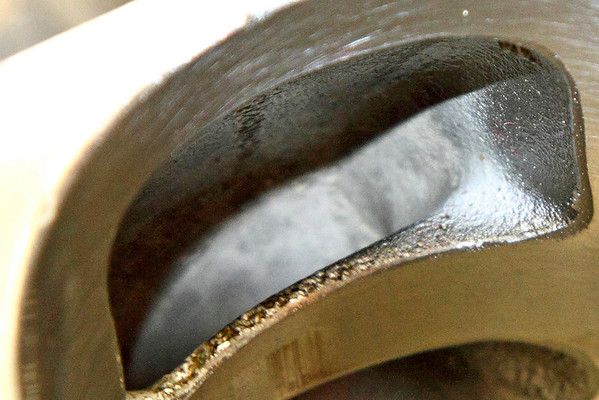

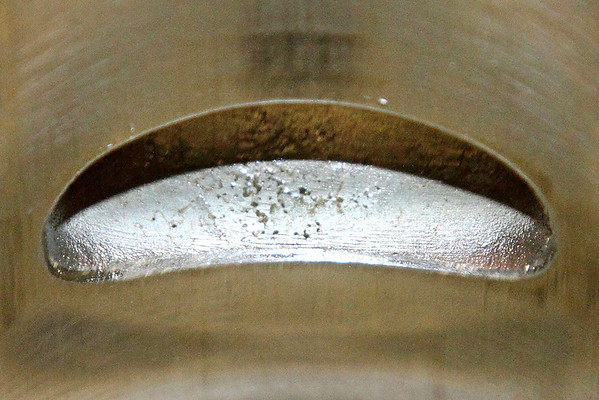

The MS660 is a touchy subject, an 066 is a different story. I've seen what a well tuned, non-ported 066 is capable of and it is nothing like a stock MS660. Personally as a work saw I'm satisfied with my MS660 just the way came from Stihl, I've added the DP muffler covers and retuned but anything else? nah, not when 372's gain soooo much better when ported(and you can still buy a new 372, the 440's are looooooong gone). Besides as soon as you hit your pride and joy 660 with a grinder, the resale value more than likely is lowered.Here's a detailed build of a 660 woods port that starts at 150 psi and ends up at 170. Timed cuts were done at several steps along the way.

Timberwolf's 660 build

If I remember correctly, even TW once said that in some cases, dropping the jug to raise compression may actually slow the saw down, unless port timing is adjusted to compensate.

Since we are talking about the 660, which has excessive exhaust duration, its exhaust port timing may actually benefit from dropping the jug.

It's ultimately up to the customer whether he wants a pop-up. If he wants a 145 psi 660, that's his call.

No argument about the quality of recent Stihl jugs. If only Stihl would make better jugs, with sane timing and a healthy compression ratio ......As it is, they're getting spanked by the competition.

I kinda question those pop up set ups as far as reliability. They great in 5 seconds of video, but what about a days work of milling?