gemniii

Addicted to ArboristSite

- Joined

- Aug 2, 2009

- Messages

- 1,502

- Reaction score

- 166

OK - Brad has a GREAT thread there, now at 780 posts.

I'm primarily interested in numbers, but left in a few pics.

I'm going to break it up into separate posts,

This is mainly a selfish thread so I don't have to wade thru 800 posts. My purpose is to try and condense it without going down to two words:

660's rule

(Hey! I'm biased, and bi-660)

pg1

I'm primarily interested in numbers, but left in a few pics.

I'm going to break it up into separate posts,

This is mainly a selfish thread so I don't have to wade thru 800 posts. My purpose is to try and condense it without going down to two words:

660's rule

(Hey! I'm biased, and bi-660)

pg1

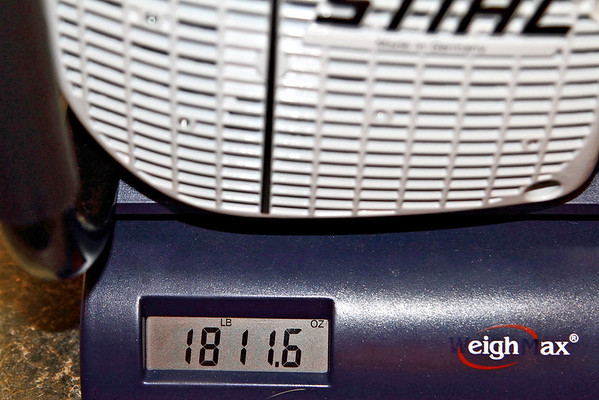

The purpose of this thread is to document the comparison of a 390XP, MS660, and 7901. The 7901 is already modded and will be compared to the other two in stock configuration. I will then mod both the 390XP and MS660, and compare them to the 7901 again.

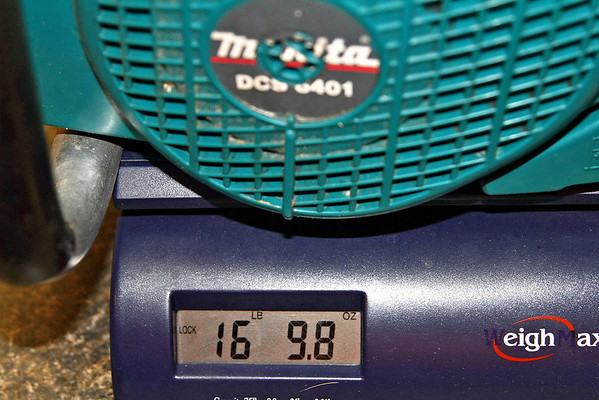

These saws all belong to Matt, aka MCW. This testing is being done at his request and to satisfy your curiousity as wellA 395XP was going to be thrown in the mix, but it was determined that for Matt's purposes, the 390 would be all he might ever need, and is significantly lighter.

The 390XP just came this afternoon. I'll be picking up the MS660 this evening.

The 390 and 660 will be getting my typical woods port. They will be initially tested with 7-pin rims and 24" bars with the same chain. There will be no muffler mods or anything the first time around.

All three saws are full of fuel and oil.

Normal load

- 7901 by a wide margin

- 390 by a few hundredths

- 660 almost identical to 390

Max load

- 7901

- 660 by a considerable amount less than the 390

- 390

What you can't see is that the 660 feels considerably stronger in the cut under max load than what the times suggest.

<object width="640" height="385"><param name="movie" value="http://www.youtube.com/v/JbsYb2sjqIc&hl=en_US&fs=1&rel=0"></param><param name="allowFullScreen" value="true"></param><param name="allowscriptaccess" value="always"></param><embed src="http://www.youtube.com/v/JbsYb2sjqIc&hl=en_US&fs=1&rel=0" type="application/x-shockwave-flash" allowscriptaccess="always" allowfullscreen="true" width="640" height="385"></embed></object>[/

Last edited: