You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A Tale of Three Saws

- Thread starter blsnelling

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

What's the squish?

Did that kit come from a different manufacturer or is it one of the older kits that baileys uses I wonder?

We're not sure. It has many of the signatures of the previous generation Baileys kit, except the combustion chamber is cleaner. The last gen from Baileys has raised the floor of the exhaust port to fix the free-porting issue, greatly improved the combustion chamber, and I believe reduced the size of the combustion chamber. I have a prototype of the last gen, and it screams. It's the first ported 066 I've done that made me go wow.

What's the squish?

About .025 with the original gasket. I now have it set to .018-.020.

mtngun

Addicted to ArboristSite

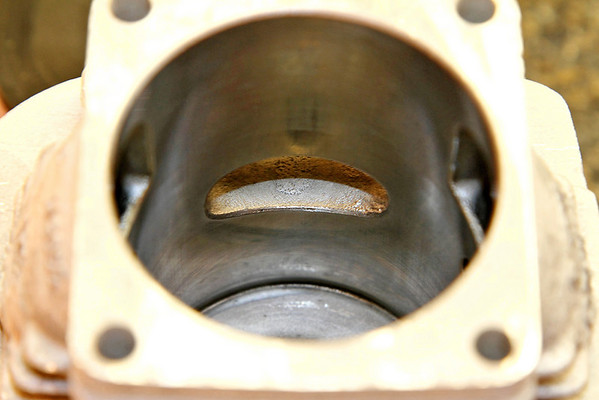

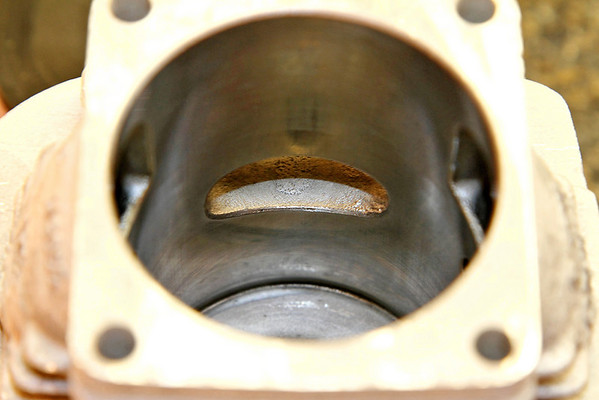

From Brad's photos of the OEM 660 P&C (thanks Brad  )

)

That dark ring at the top of the bore is suspicious.

If the saw has been run, the dark ring may merely be carbon, which is normal on a jug that has been used.

You shouldn't see a dark ring on an unused jug, though. If you do, chances are it is missing plating and/or it was gouged by the boring bar that cuts the squish band.

)

)That dark ring at the top of the bore is suspicious.

If the saw has been run, the dark ring may merely be carbon, which is normal on a jug that has been used.

You shouldn't see a dark ring on an unused jug, though. If you do, chances are it is missing plating and/or it was gouged by the boring bar that cuts the squish band.

From Brad's photos of the OEM 660 P&C (thanks Brad)

That dark ring at the top of the bore is suspicious.

If the saw has been run, the dark ring may merely be carbon, which is normal on a jug that has been used.

You shouldn't see a dark ring on an unused jug, though. If you do, chances are it is missing plating and/or it was gouged by the boring bar that cuts the squish band.

It only has a couple minutes on it, not enough to even get it hot.

We're not sure. It has many of the signatures of the previous generation Baileys kit, except the combustion chamber is cleaner. The last gen from Baileys has raised the floor of the exhaust port to fix the free-porting issue, greatly improved the combustion chamber, and I believe reduced the size of the combustion chamber. I have a prototype of the last gen, and it screams. It's the first ported 066 I've done that made me go wow.

That's what I was wondering. I heard the last generation was way better than the others. I almost want to try a 660 again.

mtngun

Addicted to ArboristSite

Right.It only has a couple minutes on it, not enough to even get it hot.

So I'm very suspicious that the dark ring is a bad spot. Prolly fine with the stock piston, but a pop-up piston in that jug may be out of the question.

porky616

ArboristSite Operative

ive installed the other 066bb kit that matt had on my old magnum. i did nothing other than a new set of rings, bolt it on and start cutting. very impressed with it but its the first bb kit ive used. have put 6 tanks of juice through it so far and its as strong as. will get some compression readings after work and post em here for everyone to see.

ive installed the other 066bb kit that matt had on my old magnum. i did nothing other than a new set of rings, bolt it on and start cutting. very impressed with it but its the first bb kit ive used. have put 6 tanks of juice through it so far and its as strong as. will get some compression readings after work and post em here for everyone to see.

Did you check skirt to case clearance? This one only touched slightly, but could be heard and felt rocking the flywheel back and forth. I clearanced the case, and cleared it up.

Have you checked compression?

FATGUY

Addicted to ArboristSite

- Joined

- Jun 2, 2008

- Messages

- 6,535

- Reaction score

- 1,546

Right.

So I'm very suspicious that the dark ring is a bad spot. Prolly fine with the stock piston, but a pop-up piston in that jug may be out of the question.

I'd love to do a pop-up for him but can not lower the jug anymore. Plus with the squish already set at .018, you won't get much from a pop-up.

I'd love to do a pop-up for him but can not lower the jug anymore. Plus with the squish already set at .018, you won't get much from a pop-up.

He was referencing the original topend

porky616

ArboristSite Operative

Did you check skirt to case clearance? This one only touched slightly, but could be heard and felt rocking the flywheel back and forth. I clearanced the case, and cleared it up.

Have you checked compression?

skirt cleared ok no tapping or knocks, aint checked compresion yet, long day at work

MCW

Somebody's talking crap here & it ain't the tree!

Thanks for the feedback on the kit Brad. As mentioned in my email to you I have passed on your information to the Chinese supplier who assures me he will look into it.

Will received one of the 372XP BB kits today so I'll wait to see what he finds after he runs it.

Basically I was contacted via email by a Chinese supplier who I gather saw my contact details from this site. Initially I was sceptical but a few of the attached pictures in his email got my attention. After shooting a few emails back and forth we came to the agreement that he would send me 2 x 372XP BB kits, 2 x 395XP BB kits, and 2 x 066/660 BB kits to test. He also has sent 4 bars to test however DHL has lost this parcel In all honesty the bars don't interest me.

In all honesty the bars don't interest me.

The 2 x 395XP BB kits were getting sent later and may or may not have arrived. I am in Tasmania getting stuck into some trees and having a ball so unsure if the parcel has arrived at my work (I'll post videos and pictures when I return to the mainland ).

).

All of these kits have been sent to AS members to test. So far the 372XP BB kit sent to Al (AUSSIE1) did not come up to scratch as whoever had ground the casting dags off one of the ports had got a bit too excited. Al said that particular kit would not have made compression. The kit that went to Will had the hole missing to access the cylinder bolts so both 372XP BB kits had faults.

To my supplier's credit he is sending replacement kits and was quite upset that I have had issues. At this stage 3 out of the 4 kits have had issues so slowly does it at my end. I'll wait to see how Aaron's BB kit on his 066 goes after a few hours of use.

Once these issues are sorted I will only be continuing with the kits that I am confident in even if that means dumping the 066/660 BB kits from my inventory.

With the current pricing and our exchange rate I should be able to land these kits anywhere in the US or Canada for under USD$100 but won't be doing so for a few months yet. I'll wait to see the outcome of the Husky kits first.

I'm in no rush

Oh and by the way the Makita and the 390XP in this thread are absolute weapons. That Makita has been wearing a 24" bar and the 390 a 32" bar and they are making mince meat of Stringybark and very hard Tasmanian Blue Gum while away

Will received one of the 372XP BB kits today so I'll wait to see what he finds after he runs it.

Basically I was contacted via email by a Chinese supplier who I gather saw my contact details from this site. Initially I was sceptical but a few of the attached pictures in his email got my attention. After shooting a few emails back and forth we came to the agreement that he would send me 2 x 372XP BB kits, 2 x 395XP BB kits, and 2 x 066/660 BB kits to test. He also has sent 4 bars to test however DHL has lost this parcel

The 2 x 395XP BB kits were getting sent later and may or may not have arrived. I am in Tasmania getting stuck into some trees and having a ball so unsure if the parcel has arrived at my work (I'll post videos and pictures when I return to the mainland

All of these kits have been sent to AS members to test. So far the 372XP BB kit sent to Al (AUSSIE1) did not come up to scratch as whoever had ground the casting dags off one of the ports had got a bit too excited. Al said that particular kit would not have made compression. The kit that went to Will had the hole missing to access the cylinder bolts so both 372XP BB kits had faults.

To my supplier's credit he is sending replacement kits and was quite upset that I have had issues. At this stage 3 out of the 4 kits have had issues so slowly does it at my end. I'll wait to see how Aaron's BB kit on his 066 goes after a few hours of use.

Once these issues are sorted I will only be continuing with the kits that I am confident in even if that means dumping the 066/660 BB kits from my inventory.

With the current pricing and our exchange rate I should be able to land these kits anywhere in the US or Canada for under USD$100 but won't be doing so for a few months yet. I'll wait to see the outcome of the Husky kits first.

I'm in no rush

Oh and by the way the Makita and the 390XP in this thread are absolute weapons. That Makita has been wearing a 24" bar and the 390 a 32" bar and they are making mince meat of Stringybark and very hard Tasmanian Blue Gum while away

Last edited:

I'm back to the drawing board with the OEM topend. Here are the specs with the original gasket.

Squish .020"

Exhaust - 94°

Transfers - 120°

Intake - 80°

Blowdown - 26°

The exhaust is just as high, but will not have to be raised to get a good shape. Also, I'll be doing a popup on this piston, gaining back some of the compression lost with the high exhaust port timing.

Squish .020"

Exhaust - 94°

Transfers - 120°

Intake - 80°

Blowdown - 26°

The exhaust is just as high, but will not have to be raised to get a good shape. Also, I'll be doing a popup on this piston, gaining back some of the compression lost with the high exhaust port timing.

Grande Dog

ArboristSite.com Sponsor

Howdy All,

If these kits are coming from China, they are not from the same manufacturer as ours. I might have mentioned this before but, there is a push of knock offs of the knock offs. They're even knocking off the packaging. The companies we deal with have started putting the Taiwan flag on their packaging, and soon it'll be on the product. They're doing this because it's one thing the Chinese wont copy.

Regards

Gregg

If these kits are coming from China, they are not from the same manufacturer as ours. I might have mentioned this before but, there is a push of knock offs of the knock offs. They're even knocking off the packaging. The companies we deal with have started putting the Taiwan flag on their packaging, and soon it'll be on the product. They're doing this because it's one thing the Chinese wont copy.

Regards

Gregg

mtngun

Addicted to ArboristSite

Thanks for the info, Grande Dog. I didn't think your supplier would be selling "your" kits behind your back.If these kits are coming from China, they are not from the same manufacturer as ours.

To get me to switch to the Chinese kits, I'd have to see plating that goes all the way to the top, sane port timing, and superior compression.

At the moment NWP top ends seem to be better quality than either recent OEM or these Chinese knock-offs.

That's not to say that NWP kits could not be improved further.

AUSSIE1

Al.

- Joined

- Aug 25, 2006

- Messages

- 8,004

- Reaction score

- 1,979

At the moment NWP top ends seem to be better quality than either recent OEM or these Chinese knock-offs.

Not going by, particularly the last 372BB I fitted. The kit Will has sounds to be a vastly better barrel.

In the last 372BB NWP Kit I fitted. A tilted exhaust port that was lower in the centre. I had to take the duration to 161° to get the correct shape. I had to elongate the mounting holes for the screws to take. The combustion chamber had really bad sand casting that needed some work. I had to tap out further the thread for the antivibe spring screw.

MCW

Somebody's talking crap here & it ain't the tree!

The biggest problem with Chinese manufacturers is that they don't care who they sell to. My supplier is pulling kits from a number of sources and not manufacturing any of these P&C kits themselves. Even I don't know where these kits are coming from and whether some of them are the same as the Bailey's kits or not. Nothing can be guaranteed in China

mtngun

Addicted to ArboristSite

The Baileys kits are made in Taiwan, not China.Nothing can be guaranteed in China

Similar threads

- Replies

- 31

- Views

- 2K