Mastermind

Work Saw Specialist

We talk a lot about compression, port timing, muffler mods, etc. We don't talk too much about the shape of the port, and how the shape relates to performance.

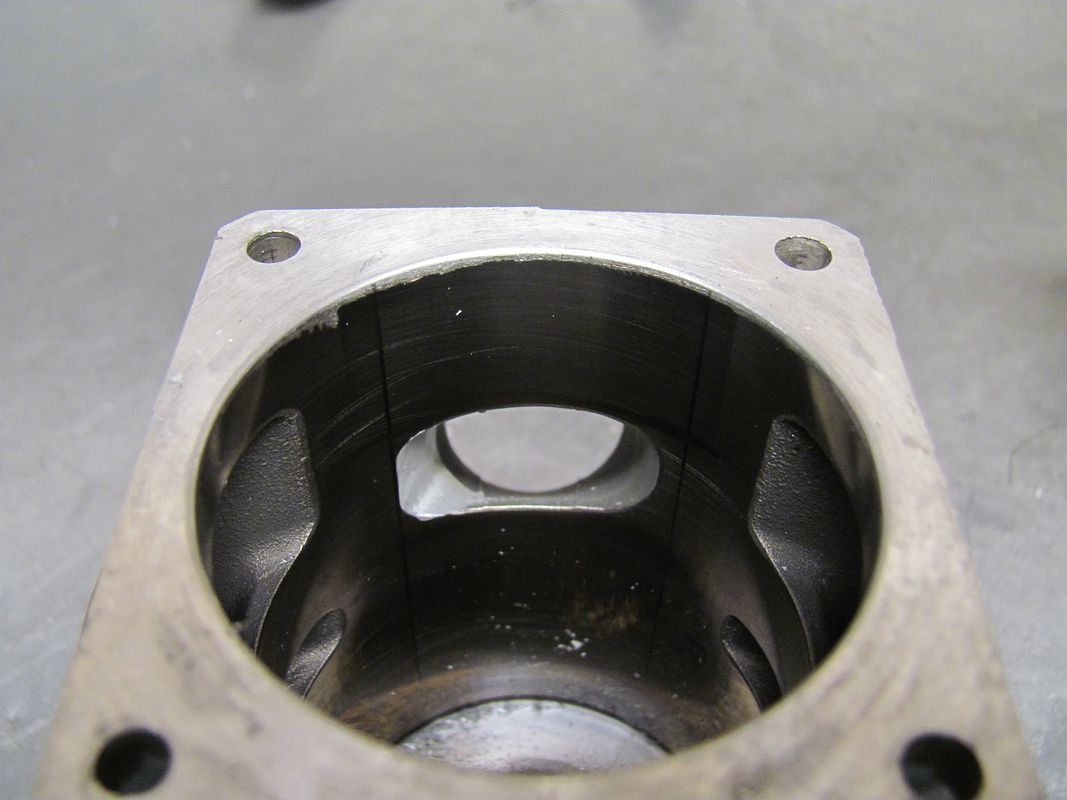

Here's a few pics of an 064 I just did.......and there's some pics of another 064 jug in here too. I sanded through the plating when I was getting the transfer off the second 064 jug.

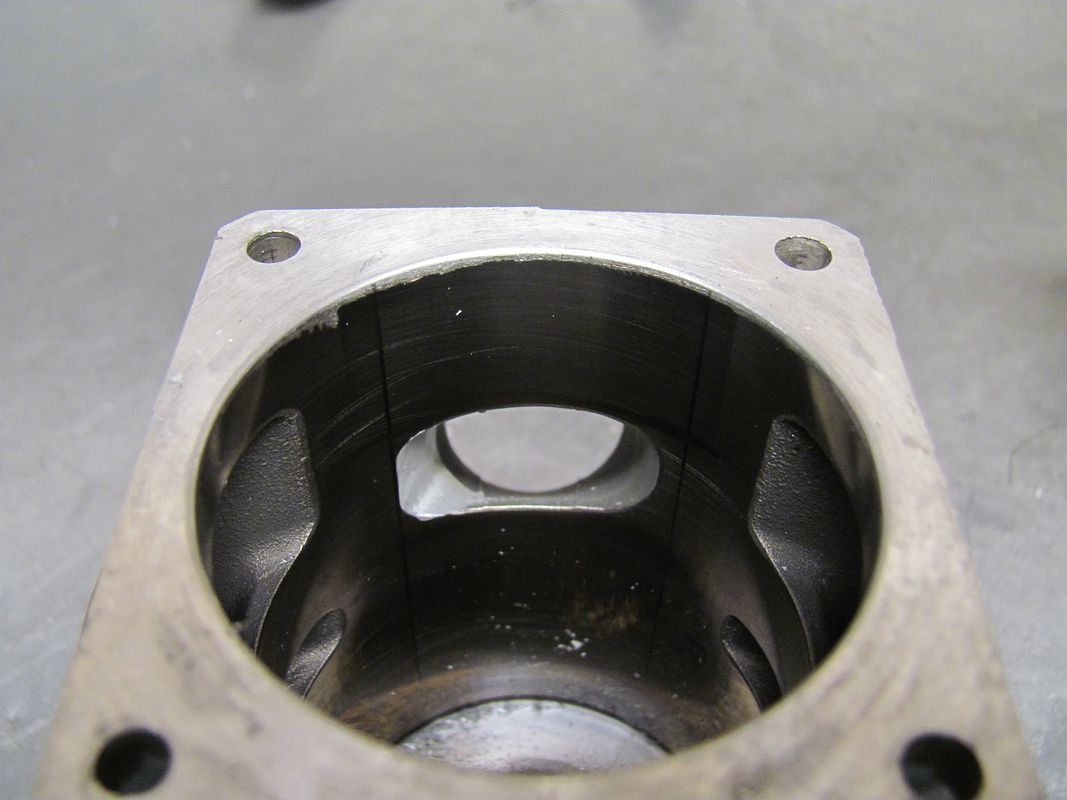

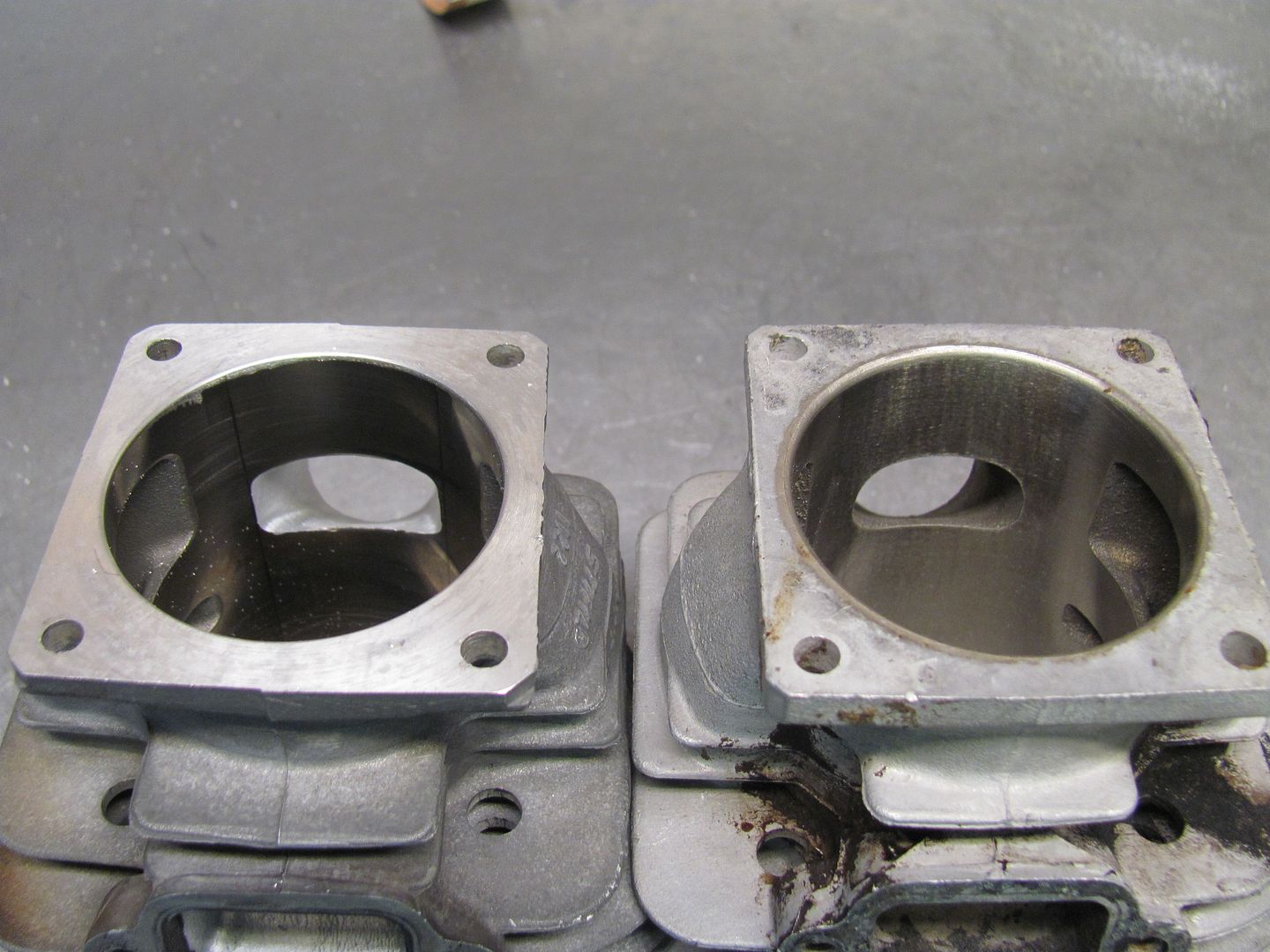

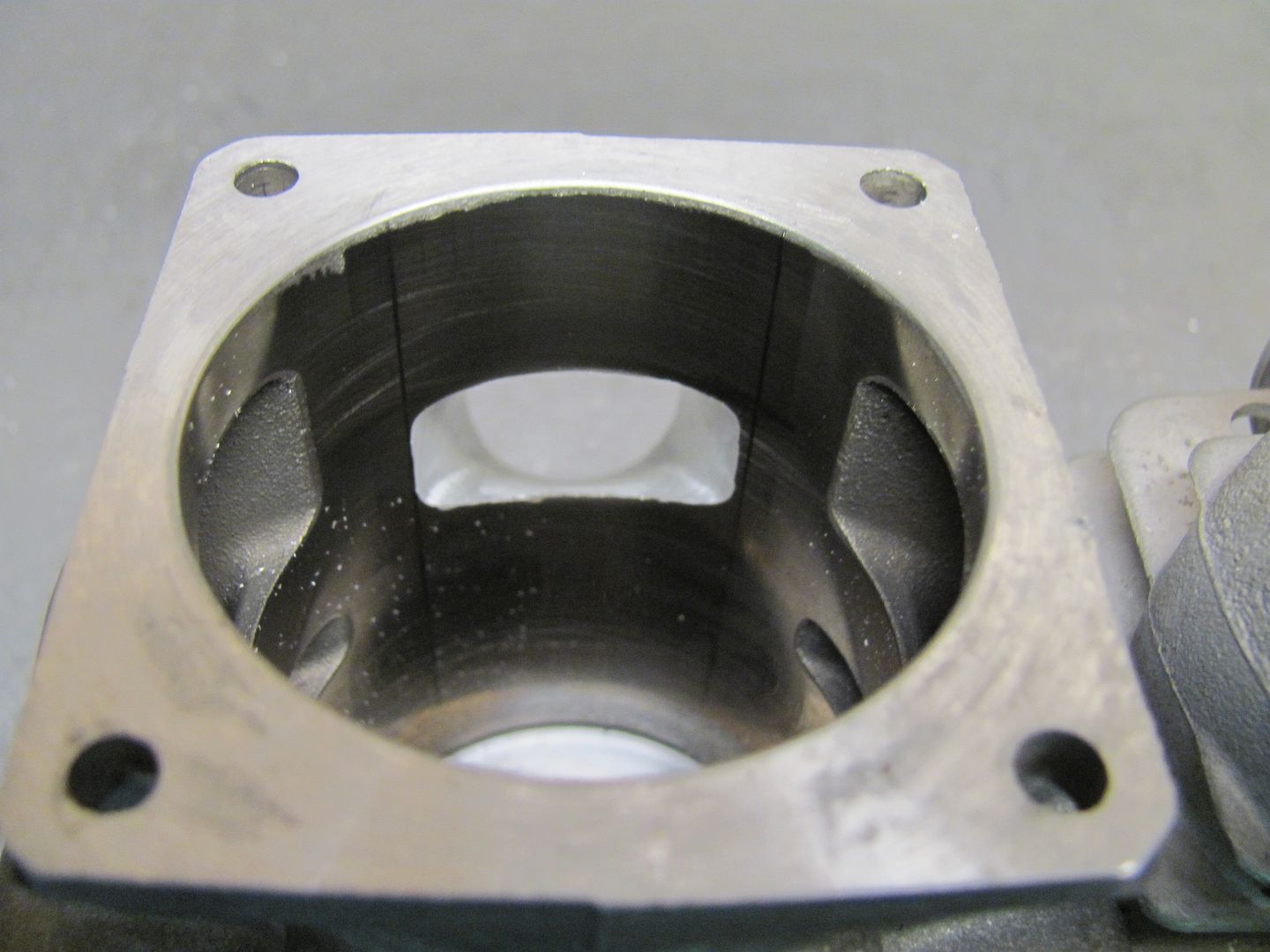

This pic really shows the difference between a "performance shape" and a stock port. Notice how the corners have been opened up to increase time area.........but the port height is unaffected.

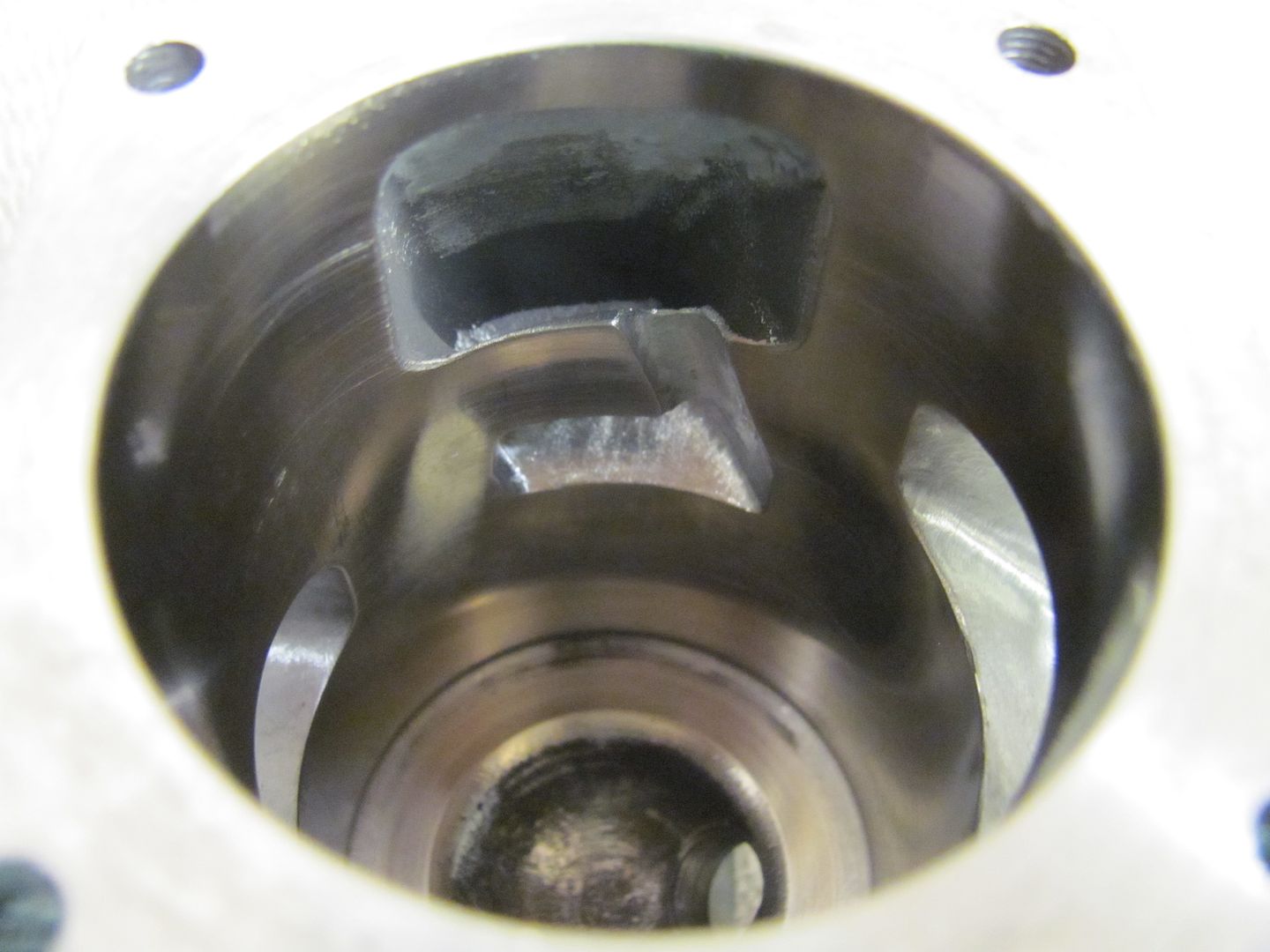

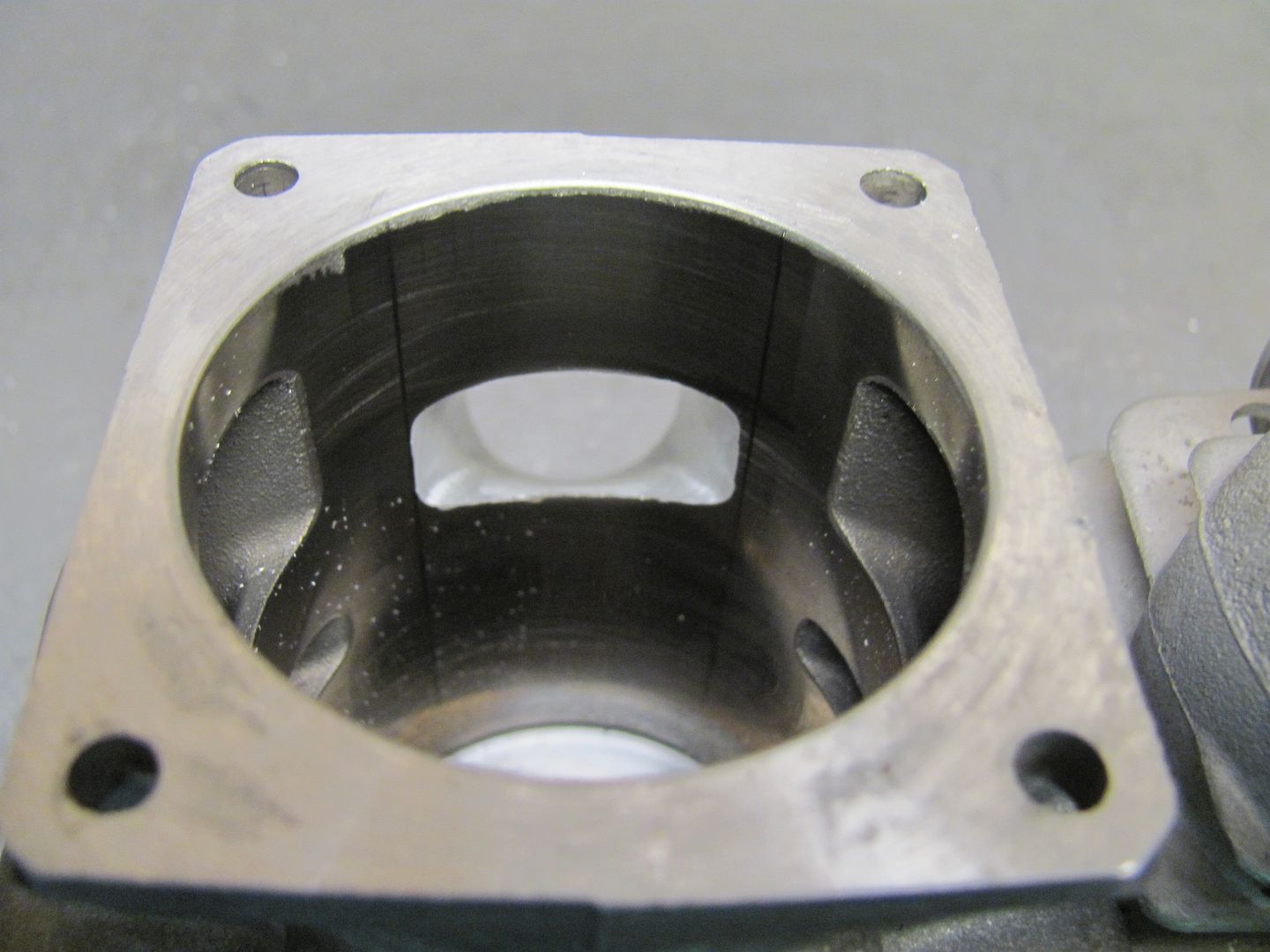

In this pic the rough in of the intake port is nearly complete......I'll tighten the corners a little more and work on out to my marks. Notice that this port is only a little wider than stock, and at the stock height. It should be plain to see that this port will be more conductive to flow than a stock port.

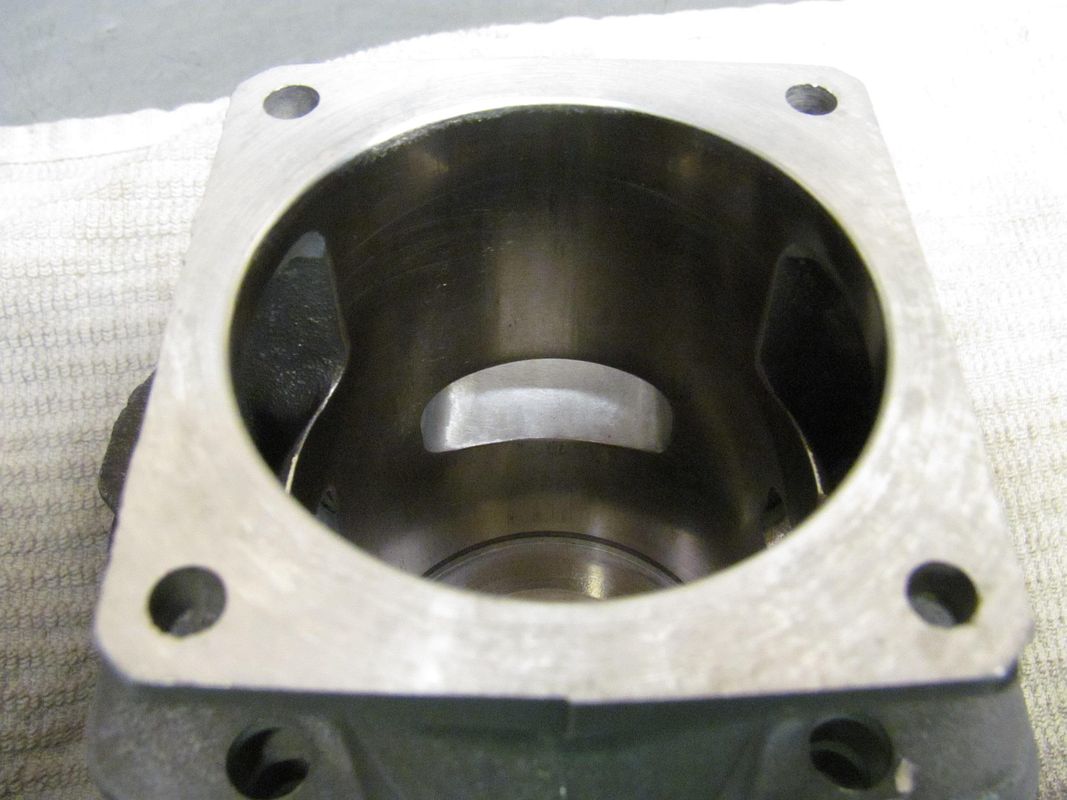

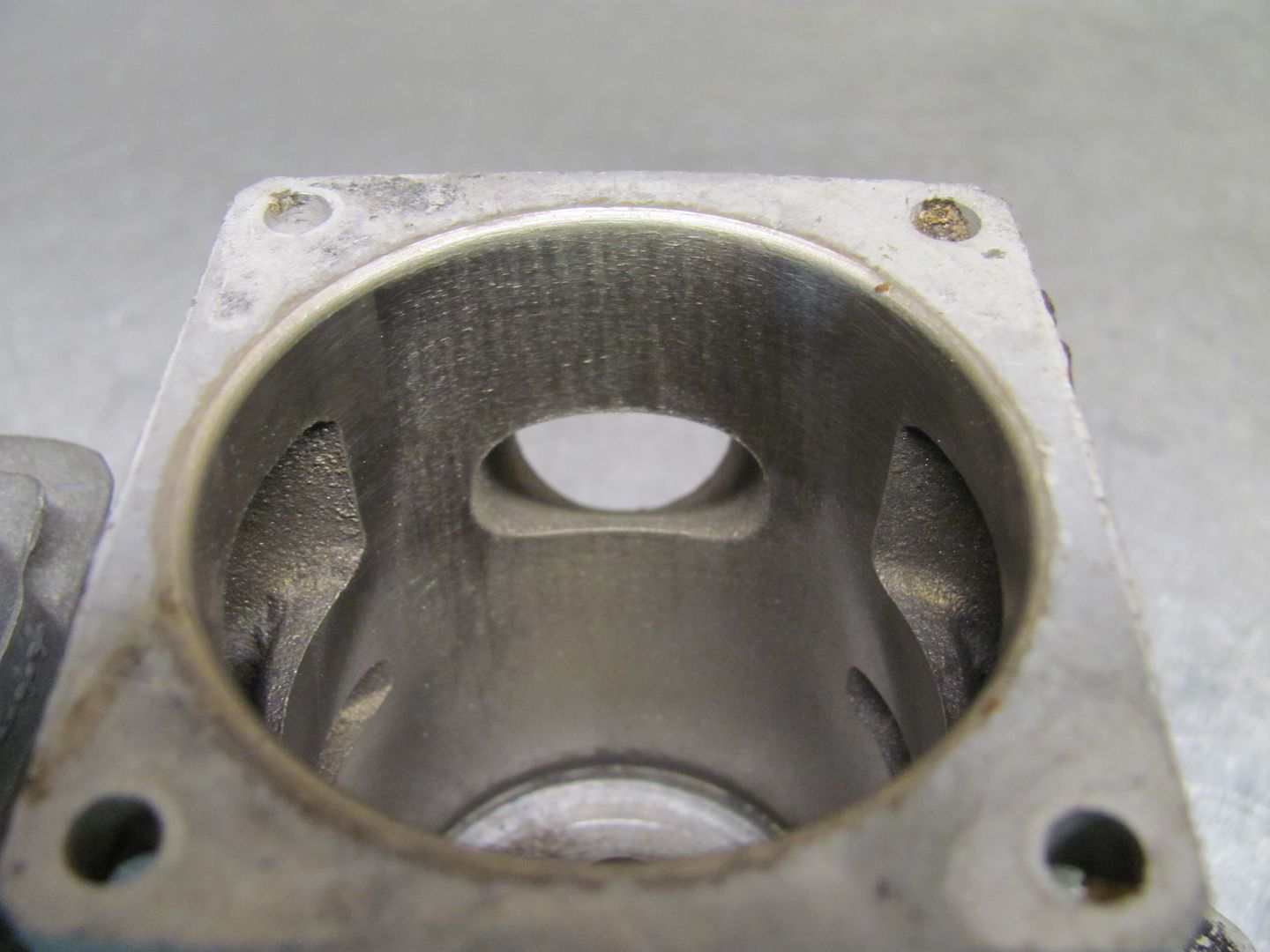

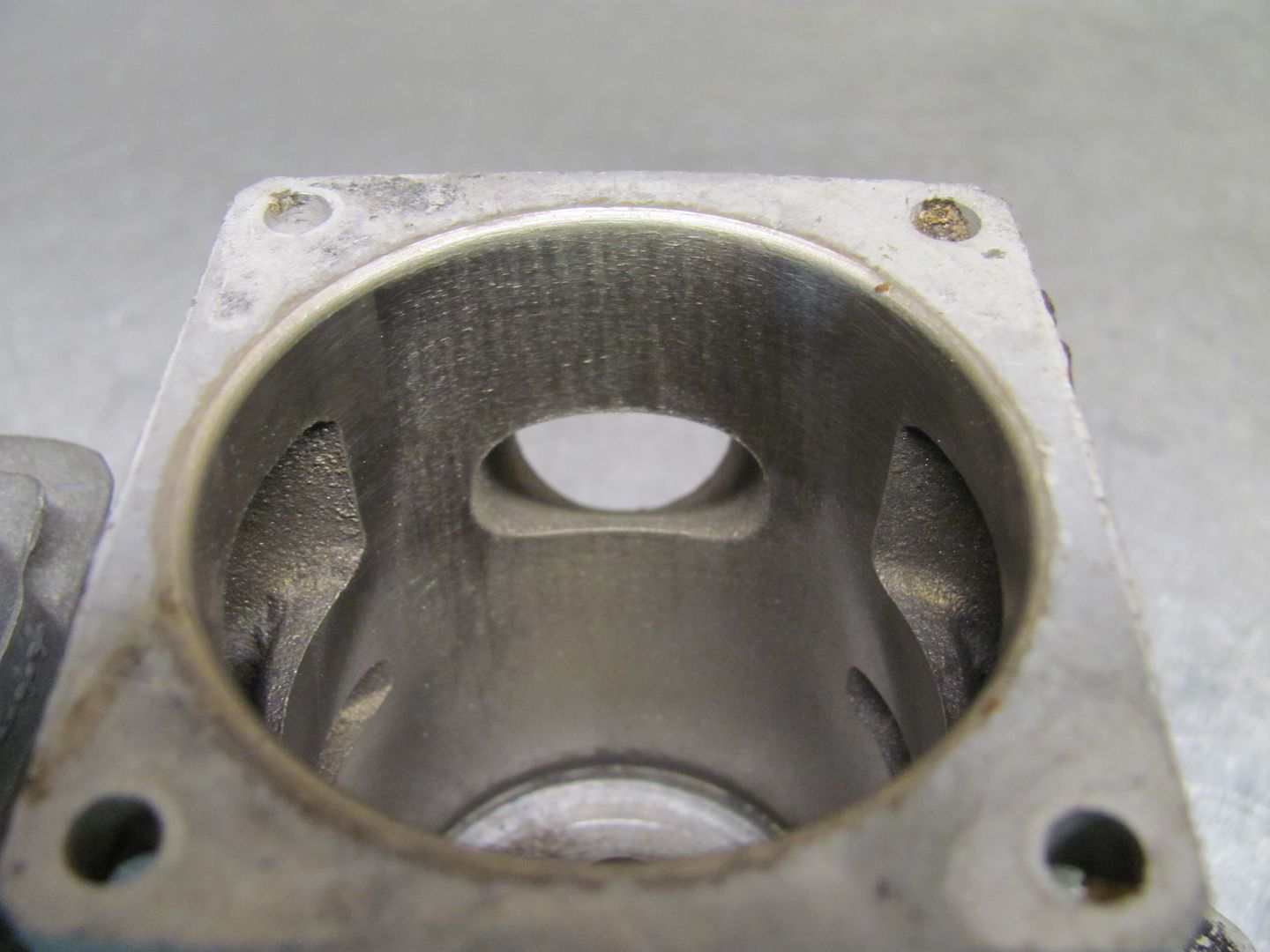

Here is a stock 064 intake port for comparison.

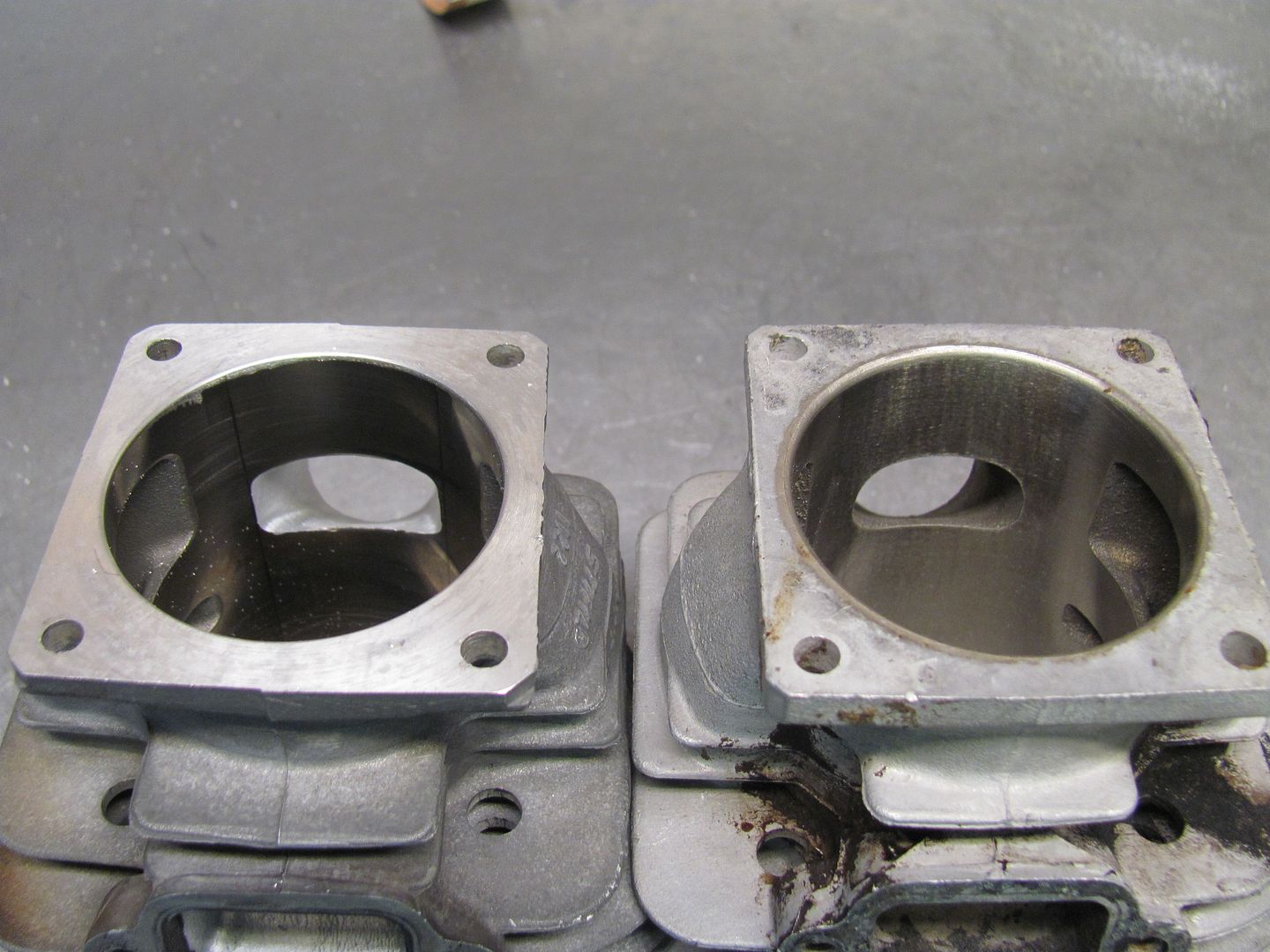

And here they are side by side.

Here's a few pics of an 064 I just did.......and there's some pics of another 064 jug in here too. I sanded through the plating when I was getting the transfer off the second 064 jug.

This pic really shows the difference between a "performance shape" and a stock port. Notice how the corners have been opened up to increase time area.........but the port height is unaffected.

In this pic the rough in of the intake port is nearly complete......I'll tighten the corners a little more and work on out to my marks. Notice that this port is only a little wider than stock, and at the stock height. It should be plain to see that this port will be more conductive to flow than a stock port.

Here is a stock 064 intake port for comparison.

And here they are side by side.