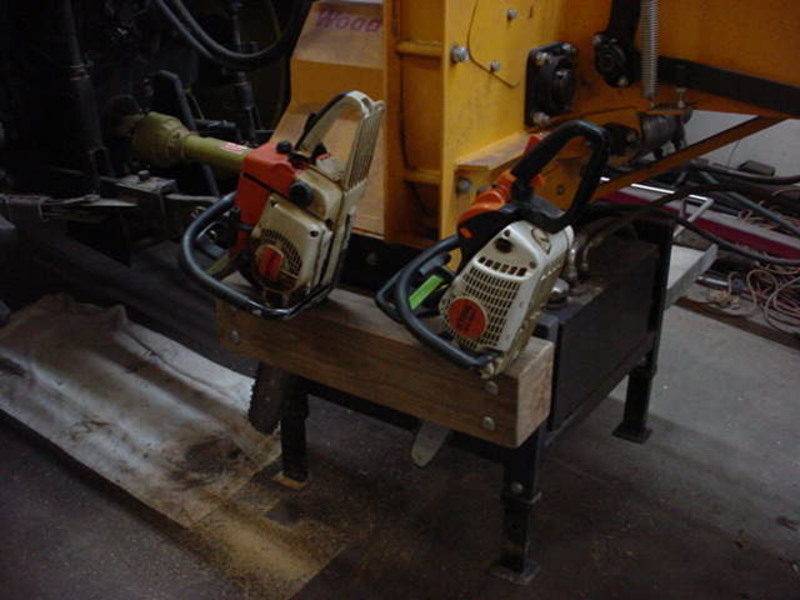

Decided to add a couple things to the Chipper. I need a place to hold the saws, pre mix, bar oil and maintenance bucket. When I chip I always need a saw and holding it or having it on the tractor moving gets old fast.

I had a length of 6x6 pressure treated and simply used some long carriage bolts to attach it to the frame. Once that was done, I plunge cut with the saw through the center.

Drilled through the upper leg box beam in the center so no strength was lost.

Bars are a ways from the ground so shouldn't have any issues. Quick and easy to get and return. Won't have any issues with falling out either.

On the other side I got some stainless angle iron and tube. Did the measuring and decided the size needed and cut triangles out of the bottom and bent them in. This is 1/8" angle so no heat was needed. On the mounting end, I cut a slit in the corner and double folded it.

Cutting the triangles and bending gives you a nicer rounded corner. Just weld the edges where they meet and plenty strong.