I guess I'll have to assume that as an engineer with access to dyno runs of trimmers, blower and chainsaws, and with a desire to defend the defend the industry that you probably work in that industry. I apologize if I have offended.

Come on man, you shouldn't try to stick an agenda accusation to a guy who is posting data. And so what if he works in that industry? Those plots stand to show you that this is a misunderstanding:

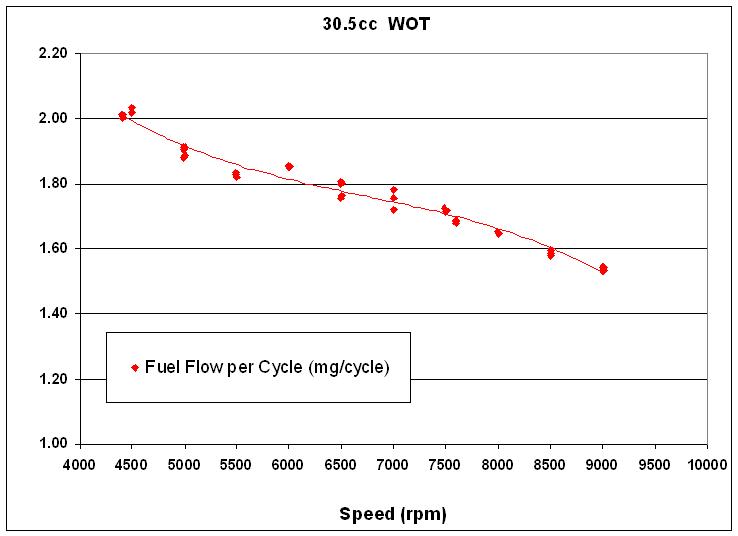

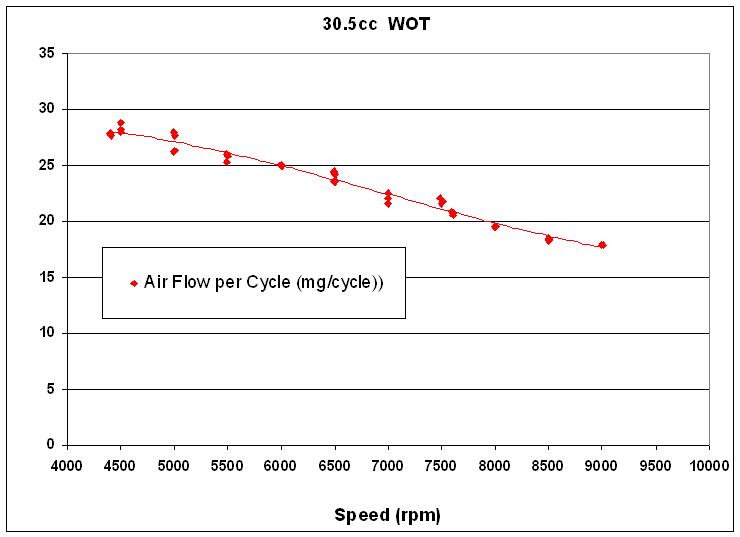

You have stated that the fuel/air ratio is not a squared function of airflow as I claimed, that it may get leaner or richer, and that max no-load WOT rpm is not due to a squared function mixture becoming terminally rich, but rather due to several other causes.

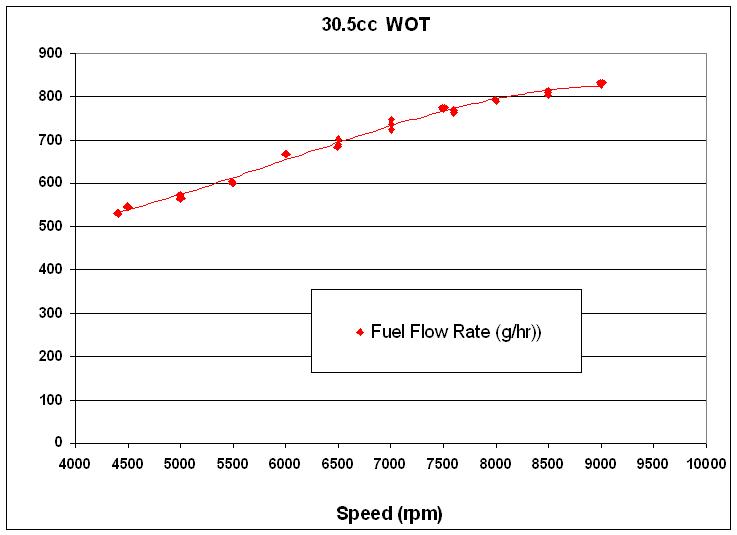

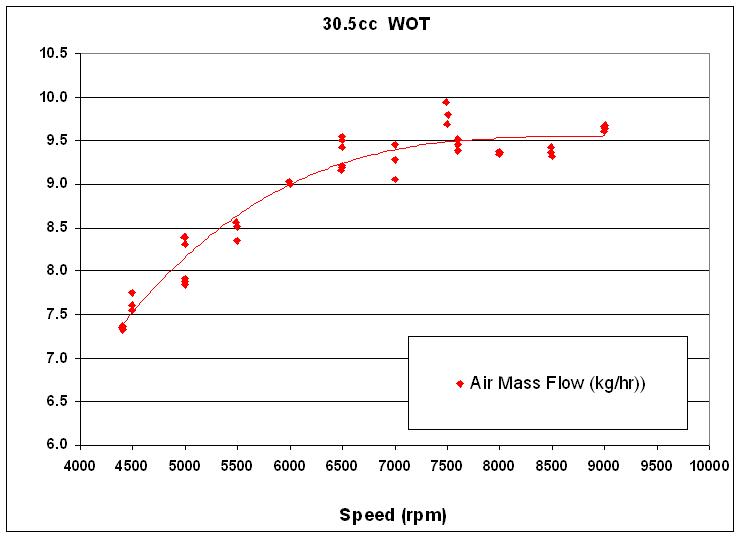

Liquid fuel flow into a venturi is a function of a pressure differential inside a carburetor barrel. That differential assumes the square of air velocity, and so fuel flow is related to velocity as a squared function. Air/fuel RATIO is not a squared function of air velocity. And the relationship of RPM to air/fuel ratio is yet another degree of separation, which introduces a lot of chaos, it's true. RPM to AFR is what the plots demonstrate. The plots are easy to interpret.

Most every manufacturer specifies a max no-load WOT rpm for purposes of setting the fuel mixture at lower rpms under load - it is an otherwise meaningless operating point. This confirms that there is in fact a consistent relationship between that terminal rpm and the fuel mixture under load, or it would be pointless.

Manufacturers also call this "max permissible RPM," which is self-explanatory in its having a "point" other than determining mixture at intermediate RPMs and loads.

Your plots do not show that region, nor do they show an engine 4-stroking which we know they do. This is not surprising as they appear to be runs to determine max HP/torque curves, not light load at all.

They show intermediate RPMs for WOT, and the explanation for those RPMs' not being WOT-max is load, because mixture is included as an axis and is clearly not the RPM limiter in this range. Whether or not mixture is the ultimate limitation doesn't matter to the relationship shown. So the plots show what we've been talking about. How often do you get data like that on a forum, man? Perk up.

Fluid dynamics was an elective I opted out of - and would again!

What is that supposed to mean? Yes, in this thread I see that you don't think fluid dynamics is relevant. But the squared relationship you've married is derived directly from either of Bernoulli's equations. I'm crying here, literally crying a river of fluids trying to show that more details about fluids matter critically to this question, and temper the relationship you're concerned about -- a relevant one, we've been saying all along.

Stihl's "intellicarb" is just connecting the diaphragm vent to downstream of the air filter rather than direct to the atmosphere. SOP for most things for decades. As for mods and experiments to linearize the fuel delivery, that problem was solved long ago via air corrector jets on fixed jet carbs or by using a CV carb with needles. Now with AutoTune coming in it seems like a wasted effort at this point. I may drill an air corrector in an old Walbro WT some day if I ever have time to play, but you'd first have to calculate the effective H jet size with the needle properly set, which would be a bit difficult.

But you started this discussion by saying that existing carbs are lame for lacking what I now understand to be correction, and because we don't know of either not-lame carb design being available for saws, I was asking to see if you thought it would be feasible to modify a carb to mitigate the variable mixture problem (which exists, but isn't as you have described). Why don't you experiment with correction on the WT and see if its general result is reducing the mixture/RPM trend? That would be proof of concept; I for one am interested. I understand the function of the intellicarb design. I'd like to try this experiment, but I think I know less about carburetor designs than you fellas do. I can tell you with some confidence what the modifications should do, but I have little knowledge of what historical carburetor designs have included and what unexpected things have accompanied those designs, etc.

I'm a bit less concerned now about lean out at lower rpm - it may be that the curve is flat enough down there that it isn't a big problem, but it would require analysis of those conditions to really tell. Other than that this has moved past the point of fruitful discussion and taken on an unpleasant undertone, so I will stop here.

Those conditions are shown in the plots.

Nah, there's no unpleasant undertone here. You've not been taken to task for your claim that there's a variable mixture issue or that there's a square somewhere in the mix. Your assumptions linking the air velocity / liquid movement relationship to a putatively identical RPM/mixture relationship, and to the handful of conditions you've described (four-stroking, RPM limitation at WOT, etc.), are just being challenged. BTW, I think the motivation for the challenge is to say "don't worry, it's not as bad as you're saying." Still a discussion full of fruit.

You don't even have to take my word for anything, just run some numbers: if the relationship even approaches a situation where MIXTURE RATIO changes as the square of RPM, then you can see just how much different AFR would be at WOT 10K vs. WOT 11K RPM in a saw if it's RICHNESS LIMITED to 11K at UNLOADED WOT. It doesn't have to be all the way to square -- a concave-up function with much curvature will do.

Now, pleasantly undertoned about the fruit:

How and where will you drill your WT? You're talking about adding a jet to the fuel delivery carb inlet, which is what a corrector jet is, right? Not adding an air inlet to the venturi, which has been what I've been trying to think about?

I've been thinking about how the air valve in a strato engine should flatten the mixture/RPM relationship like you were saying. It should have that general effect, and very generally, any small leak in the stream delivering fuel fluid from venturi to combustion chamber should have the effect of flattening the relationship. It flattens them to "too lean everywhere, saw cooked" when uninvited, but it ought to be easy enough to see if experimenting with the idea can lead to a saw that leans LESS when loaded.