robfromaz1977

Addicted to ArboristSite

What's this orange and white fluid flowing from the cuts in my back?:msp_biggrin:

Here put a couple of these on them!

What's this orange and white fluid flowing from the cuts in my back?:msp_biggrin:

Stihl could sell more of their premium oil if it suggested 40:1.

If 40:1 made the saws more durable/reliable or perform better, it would be in Stihl's interest to suggest that ratio.

But Stihl suggests 50:1, even during break-in.

Not knocking anybody, just curious - what is it that people seek to gain via 40:1 (or even richer) and how does the richer mix acheive that goal?

Thanks

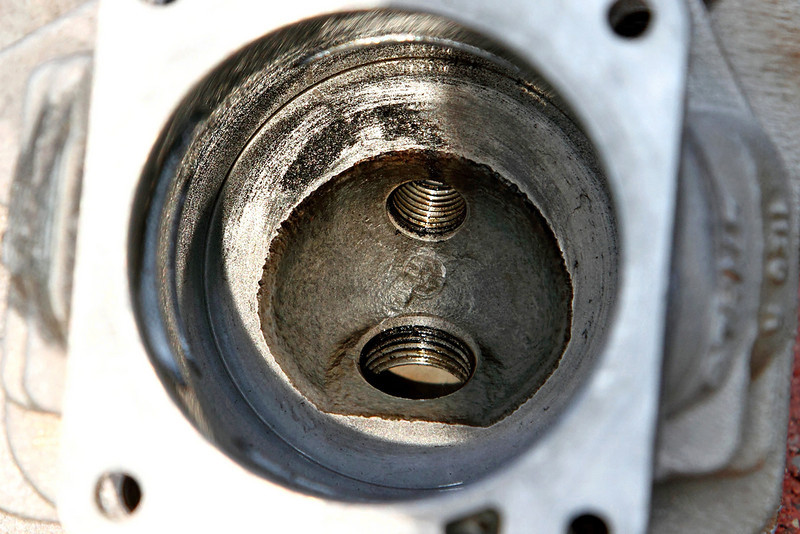

Here is a piston and cylinder that was out of a Stihl 441 that was run on 100:1 Amsoil. I think I'll pass on the 100:1 BS.

here put a couple of these on them!

I had a guy running Klotz at 40:1 that seized his Shindaiwa trimmer engine right up. Tore it down, to find both the piston & cylinder were virtually undamaged, just a heavy buildup of gummy tar. I thought it may have been a problem with his fuel, but he was running all his saws (has a ton of them) out of the same can, with no problems.

I had a guy running Klotz at 40:1 that seized his Shindaiwa trimmer engine right up. Tore it down, to find both the piston & cylinder were virtually undamaged, just a heavy buildup of gummy tar. I thought it may have been a problem with his fuel, but he was running all his saws (has a ton of them) out of the same can, with no problems.

Here put a couple of these on them!

Thats because trimmers are not run wide open for the most part...

they also dont run the 14,500 rpms that saws do...

[snip]

Ok, this thread seems to pop up every month or so....

More oil = more power. There's plenty of (racing) data out there to show this.

It's as simple as giving a better ring seal, even with the good racing oils (which tend to be heavier SAE 40 and 50 rather than the SAE 20 which most JASO FC/FD equivalent oils are)

Saw companies recommend 50:1 as

a) Stock saws have low BMEP's, (Brake mean effective pressure, a fancy term to describe specific outputs. ie. power output/cubic capacity)

This means they create less heat than other high performance two strokes so they can survive quite well on a leaner mix diet..

b) They also rev less than racing two strokes under load

I'm talking in the cut revs. These are usually somewhere from 8,500 to 10,500 RPM.

Really high performance two strokes pull much more revs at the end of a straight than a stock saw sees in the cut, anywhere up to 22,000RPM. (no, I'm not exaggerating)

Tuning revs don't really count.

c) The average saw doesn't get serviced much, let alone opened up. 50:1 may produce less carbon than 40:1 over the working life of the average saw, particularly when less than great quality oils are used.

d) Having said that, a lot of saw companies still recommend 40:1 when using non saw branded oils, (eg Dolmar) so therefore if the saw company says 40:1 is OK, I can't see an issue using 40:1 all the time.

e) The bigger saws still use richer mix's, eg. Husqvarna stipulate 25:1 in the 3120 here, and I'm pretty sure Stihl does in the 880 too.

Both of these big boys have much higher no load RPM limits than the same model saws sold in the US and are often used for milling or post ripping, so are used for long, sustained cuts.

Long cuts = lots of heat so a greater potential for skirt scuffing and seizing.

Really high output air cooled two strokes still use 16-20:1 mix ratios, even with the very best castor/syn oils like Elf HTX 976 & 909, Castrol A747 & XR77, Silkolene KR2, etc.

These type of oils are that much better than oils like Stihl Ultra under high load/high temps/high RPM's it isn't funny, yet the engines that run these oils still require 'rich' mixes to survive.

Yes, these type of engines come apart every meeting or so, so potential carbon build up isn't an issue, but they still run very cleanly (especially compared to the straight castors that I used to run 25 years ago)

Respected Stihl shops in logging areas here (Australia) recommend 40 and 32:1 to their pro customers running 660's according to MCW.

One shop owner said to Matt they definitely see less wear on the top ends of 660's with the slightly more oil in the mix saws.

Tzed250 posted some photos of one of his saw engines in a thread like this some time back using a mix IIRC of Ultra and Klotz ??

Anyway, pretty sure it was @ 32:1 and it was clean enough on the top end to eat your dinner off.

It was a combination of good oils, good fuel and a well tuned saw.

A saw doesn't see those sort of revs under load, it's for maybe a second before the cut starts and that's it.

High no load revs aren't good for a saw either.

While I would not run 100:1, I have used AMSOIL for 20 years at 40:1 and have never seen carbon like that! I run it in my sport quad, my 85 hp Banshee, my saws, you name it.

While I would not run 100:1, I have used AMSOIL for 20 years at 40:1 and have never seen carbon like that! I run it in my sport quad, my 85 hp Banshee, my saws, you name it.

Ok, this thread seems to pop up every month or so....

More oil = more power. There's plenty of (racing) data out there to show this.

It's as simple as giving a better ring seal, even with the good racing oils (which tend to be heavier SAE 40 and 50 rather than the SAE 20 which most JASO FC/FD equivalent oils are)

Saw companies recommend 50:1 as

a) Stock saws have low BMEP's, (Brake mean effective pressure, a fancy term to describe specific outputs. ie. power output/cubic capacity)

This means they create less heat than other high performance two strokes so they can survive quite well on a leaner mix diet..

b) They also rev less than racing two strokes under load

I'm talking in the cut revs. These are usually somewhere from 8,500 to 10,500 RPM.

Really high performance two strokes pull much more revs at the end of a straight than a stock saw sees in the cut, anywhere up to 22,000RPM. (no, I'm not exaggerating)

Tuning revs don't really count.

c) The average saw doesn't get serviced much, let alone opened up. 50:1 may produce less carbon than 40:1 over the working life of the average saw, particularly when less than great quality oils are used.

d) Having said that, a lot of saw companies still recommend 40:1 when using non saw branded oils, (eg Dolmar) so therefore if the saw company says 40:1 is OK, I can't see an issue using 40:1 all the time.

e) The bigger saws still use richer mix's, eg. Husqvarna stipulate 25:1 in the 3120 here, and I'm pretty sure Stihl does in the 880 too.

Both of these big boys have much higher no load RPM limits than the same model saws sold in the US and are often used for milling or post ripping, so are used for long, sustained cuts.

Long cuts = lots of heat so a greater potential for skirt scuffing and seizing.

Really high output air cooled two strokes still use 16-20:1 mix ratios, even with the very best castor/syn oils like Elf HTX 976 & 909, Castrol A747 & XR77, Silkolene KR2, etc.

These type of oils are that much better than oils like Stihl Ultra under high load/high temps/high RPM's it isn't funny, yet the engines that run these oils still require 'rich' mixes to survive.

Yes, these type of engines come apart every meeting or so, so potential carbon build up isn't an issue, but they still run very cleanly (especially compared to the straight castors that I used to run 25 years ago)

Respected Stihl shops in logging areas here (Australia) recommend 40 and 32:1 to their pro customers running 660's according to MCW.

One shop owner said to Matt they definitely see less wear on the top ends of 660's with the slightly more oil in the mix saws.

Tzed250 posted some photos of one of his saw engines in a thread like this some time back using a mix IIRC of Ultra and Klotz ??

Anyway, pretty sure it was @ 32:1 and it was clean enough on the top end to eat your dinner off.

It was a combination of good oils, good fuel and a well tuned saw.

I'm curious as to whether or not this is normal carbon formation on a piston crown. This is the P&C from my new MS440. It has only seen maybe a dozen tanks of fuel. The saw has not been run excessively rich, or lean for that matter. What's odd is the the combustion chamber and exhaust port are both clean. The carbon on the piston crown was extremely hard and very difficult to remove.

Most of you know that I run Klotz R50 at 32:1. My questions are this. Is this normal? If not, is this the result of running R50? Is it the result of running 32:1? What do the masses think. And please don't just blurt out, oh you're running it too rich. Give me a reason why you think what you do.

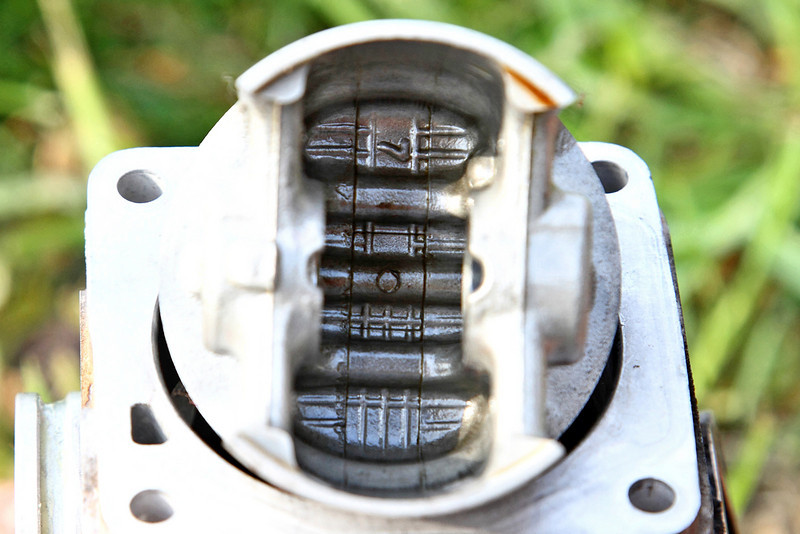

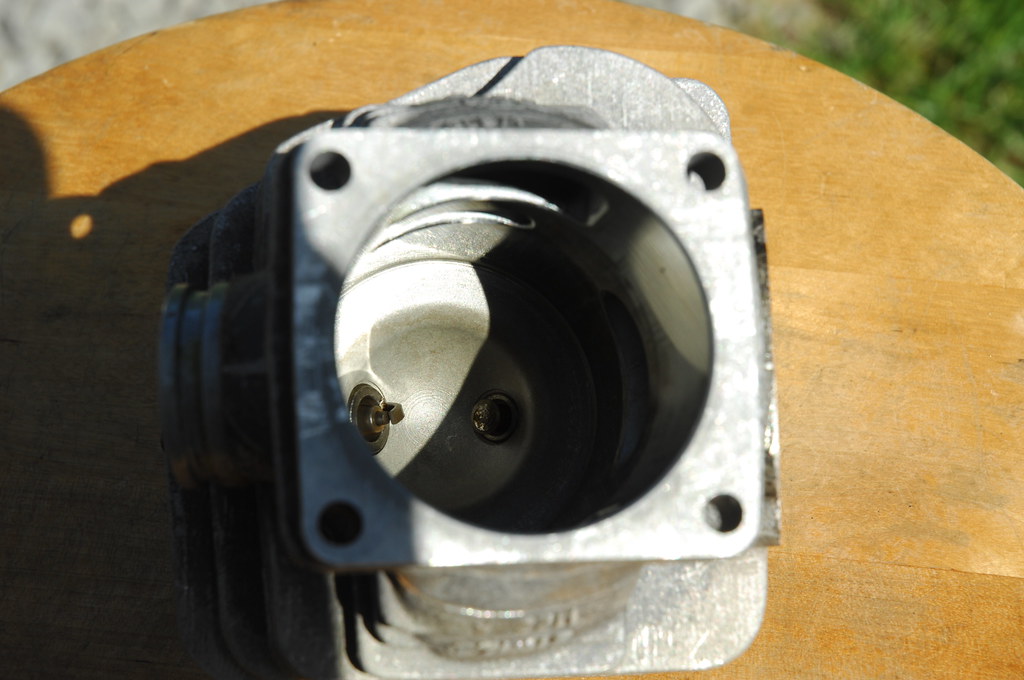

This is what I call clean.

MS660 cylinder, 6-7 tanks of Amoco Ultimate premium unleaded(10% ethanol) mixed with Stihl Ultra @ 50:1, with one ounce per gallon Klotz Super Techniplate added.

This photo was taken after the saw was used to buck 40" White Oak, so the top end was under plenty of load. No pic of the piston, but what was on the crown wiped off with a paper towel.

Notice how clean the plug is.

My $.02

...

85H.P. Banshee???? Frig, I bet you got some long arms from holding onto that beast, stretched eyelids and bugs stuck in yer teeth from grinning!!!:msp_w00t::msp_w00t::msp_w00t:

Enter your email address to join: