mtngun

Addicted to ArboristSite

A peaky power band may be able to cut just as fast, but only if the operator works hard to keep the saw in its narrow powerband. My old lame 066 BB was like that. It is not missed.Increasing the midrange should increase the speed at which it cuts cookies due to being able to lean on the saw more and/or have more aggressive chain specs.

Some saws don't sound like they are working any quicker than a stocker, but are cutting quicker.

:agree2: Yeah, and who wants a good ring seal or a smallish combustion chamber ?Real high (200 psi) cold cranking compression means nothing more than you have a good ring seal, or a smallish combustion chamber.

I guess the new popular mod on AS will be installing thicker base gaskets to reduce compression and heat, and then running the detuned saw on top of a mountain where the air is thinner, because compression is a really bad thing.

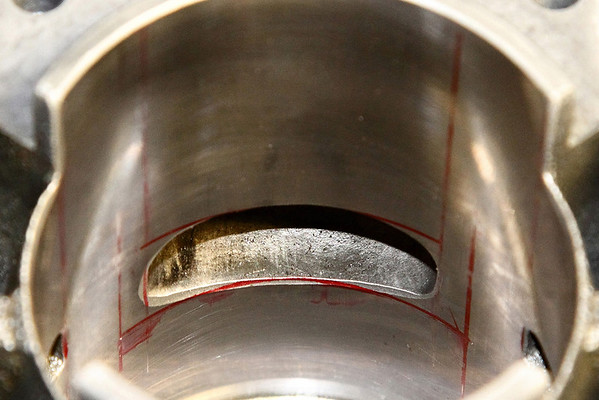

Brad, you must be a good photographer, because your closeups of the ports are awesome. Keep 'em coming.