I was finishing up some welds on the splitter and decided to run the sled down with air power..thing is it only extended to 22 inches..This is suppose to be a brand new 24 inch stoke ram..Will i get the extra 2 inches when using hydralic fluid? There is 24 inches in between the 2 ports where the hydraulic lines hook up...

Also i took the time to put a level on my ram before i welded the sled up soild..Now i didnt take into account my beam wasnt quite level so i am not quite on a perfect plain..I can make up the difference on the rear hydraulic mount by grinding some off( it isnt welded to the beam yet)bringing the ram closer to the beam thus making it parallel to the beam). However if that little bit of difference doesnt matter i am not gonna bother..

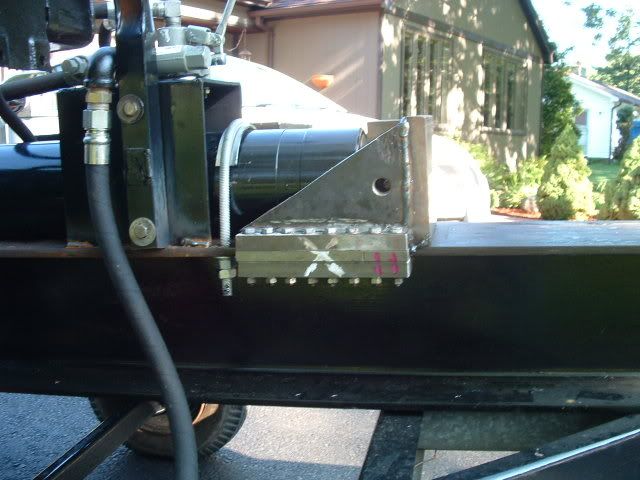

picture for reference..

Uploaded with ImageShack.us

Also i took the time to put a level on my ram before i welded the sled up soild..Now i didnt take into account my beam wasnt quite level so i am not quite on a perfect plain..I can make up the difference on the rear hydraulic mount by grinding some off( it isnt welded to the beam yet)bringing the ram closer to the beam thus making it parallel to the beam). However if that little bit of difference doesnt matter i am not gonna bother..

picture for reference..

Uploaded with ImageShack.us