Gypo Logger

Timber Baron

046 said:Simon sure seems to know the little details....

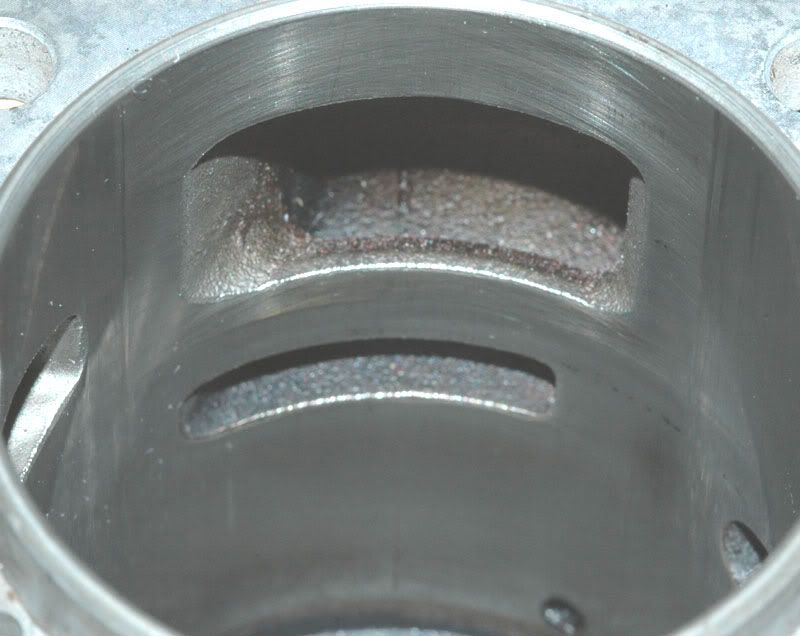

here's my porting setup with assortment of carbide bits, forward exhaust die-grinder and rear exhaust snap-on die-grinder

prefer grinding off all the ruff casting marks, then polish smooth.

Great picture of the die grinders 046. Glad you have had experience with the car motors, it will be invaluable I am sure in your endeavours with 2 cycle. Although they may be easier to work on due to the size of the cylinders, I bet a mistake is much more costly.

John