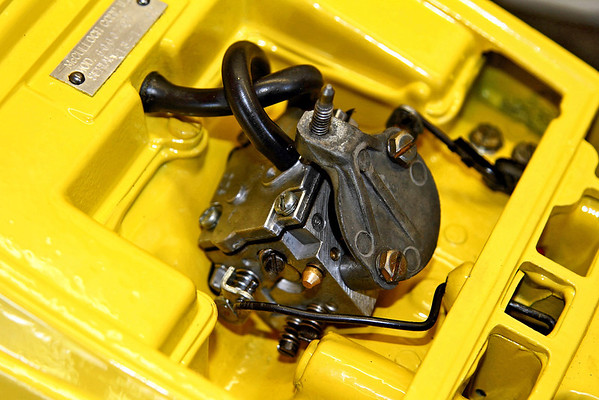

Anyone have a flywheel key for a 125? How about a front lower AV mount, the one on the bottom of the wrap handle? I also need a coil for that will work on the 101 block.

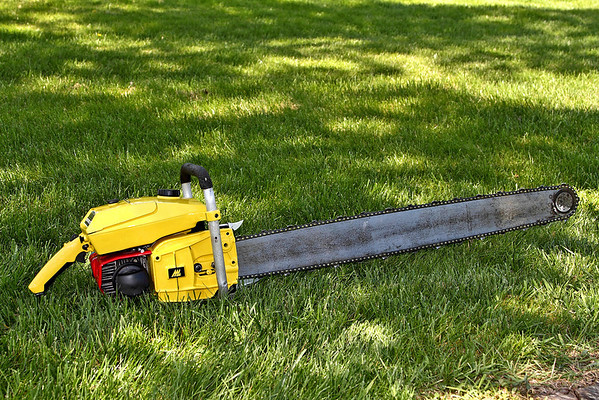

The first saw is in primer. I'll be shooting the color here shortly.

The flywheel key can be had at a hardware store.