NDtreehugger

ArboristSite Guru

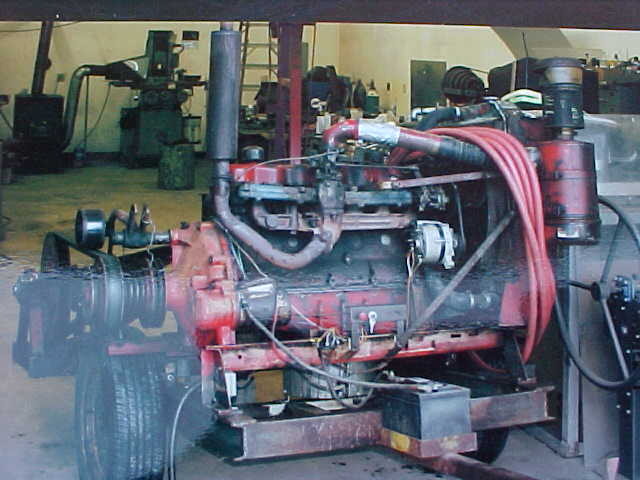

I picked up an old ford f150 the truck has a rebuilt engine, so no need for the 300 engine in my shop.

I picked this 300 up in trade for a riding lawn mower thinking I would keep it for the truck, but now it seems it will just sit their and not get used so I was thinking, I may as well make a splitter out of it.

Anyone have any ideas on the parts needed, I know Ill need the pump, hose, valve, tank and all the other stuff.

I’m thinking their should be adapters already available

I picked this 300 up in trade for a riding lawn mower thinking I would keep it for the truck, but now it seems it will just sit their and not get used so I was thinking, I may as well make a splitter out of it.

Anyone have any ideas on the parts needed, I know Ill need the pump, hose, valve, tank and all the other stuff.

I’m thinking their should be adapters already available