Heat differential approach to removing and replacing bearings has been around since there have been metal things to stuff bearings into. Need around a 250 degree difference plus or minus a little for Husqvarna cases.... Put the bearings in the freezer and use a hot plate, a wood stove, a variety of heat sources to make it easy to control the temperature of the cases. A toaster oven. All work. Used to heat cases for dirt bikes to 300 degrees. That's more than you need. But the ALL STEEL bearings would drop right in or out depending on the direction you are going. Those "nylon" caged bearings make me nervous so I don't use them even if they are OEM...... but thanks again to "Randy" for shedding a little light on the subject yet again...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Case Bearing Installation

- Thread starter Mastermind

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Stihl Ohioan

ArboristSite Operative

Thanks for this great info . I am getting ready to rebuild a ms 440 and am going to try the oil pump trick for the depth setting .

Thanks for this great info . I am getting ready to rebuild a ms 440 and am going to try the oil pump trick for the depth setting .

sunfish

Fish Head

Neal told me to heat the case halves, but I didn't, used a big hammer. Did put the bearings in the freezer. All worked well, but will heat the case next time...

I like heating the entire case vs. locally heating things. Ovens do that. Toaster ovens are good enough. That's what I use when I'm not fooling around for "farmer jones" video's using "back woods" tools to fix saws. (used a wood stove and a lazer thermometer to keep track of the temps for chits & grins in one) Works for Husqvarna's...but don't need to use an oil pump! Does it respond well to heat???

When done right, the bearings drop right in with no interference. Works with setting cranks in those bearings as well. Just don't waste time.... as soon as the temps begin to even out due to heat transfer from the warm things to cooler things.... they "bite" and now force is required defeating the purpose.

When done right, the bearings drop right in with no interference. Works with setting cranks in those bearings as well. Just don't waste time.... as soon as the temps begin to even out due to heat transfer from the warm things to cooler things.... they "bite" and now force is required defeating the purpose.

Adirondackstihl

Flyz, Fuel & Fotos

MAPP works for me.

Keep the bearings cold.

The last 4 bearings Ive installed have literally dropped right into place

Keep the bearings cold.

The last 4 bearings Ive installed have literally dropped right into place

I use a heat gun, an ir thermometer and frozen bearings. I have used an oven and it works fine, it's just that the odor in the kitchen is a bit different.... I have an ms360 and a ms440 coming up for case splitting/rebuilding.

I heat the case with a torch, careful to not burn the paint. I keep the flame moving, making about 10 passes around the bearing pocket. The bearing usually just falls in. I don't freeze the bearings either.

fatboycowen

ArboristSite Member

I'm getting ready to re-do my 385, which needs the OE sealed bearing on one side. It has a non-metallic cage (nothing i can do about it), plus the seal. Do i have to worry about the heat transfer from the case half damaging that bearing? What about the seal? Or, is 250 not hot enough to do damage?

This thread is awesome, btw.

This thread is awesome, btw.

I hit it with compressed air as soon as I drop the bearing in. I can't imagine enough hear transferring to damage the bearing and seal. It probable gets hotter during normal operation.

fatboycowen

ArboristSite Member

Sweet. I'll give that a shot. Thank you.

The bearings and race itself will absorb the heat and the seal and cage will be fine....at 250~275 degrees.

My tool of choice for heating is a toaster oven. The entire case half expands and contracts in uniform fashion instead of just stressing out locally at the bearing location. May not matter one way or another, but I have a handle on the 'relative' temperature recommended in the shop manual that way vs. just heating up the bearing seat/bore with a torch or heat gun and maybe putting undue stress on what is already a pretty stressful area of a chainsaw.

My tool of choice for heating is a toaster oven. The entire case half expands and contracts in uniform fashion instead of just stressing out locally at the bearing location. May not matter one way or another, but I have a handle on the 'relative' temperature recommended in the shop manual that way vs. just heating up the bearing seat/bore with a torch or heat gun and maybe putting undue stress on what is already a pretty stressful area of a chainsaw.

fatboycowen

ArboristSite Member

magnesium and aluminum have a very high thermal conductivity. That means if you heat one part, it will quickly transfer to other parts of the case.

Steel is much lower.

Steel is much lower.

dgeesaman

ArboristSite Lurker

Napa is still making $20. off your purchase. Do you have an industrial bearing and seal distributor in your local area? Motion bearing charges around $5. for C3 rated chainsaw bearings.

Today I paid 6.89 ea for 6202 C3 from SKF.

I agree with the Nachi being good quality, and the vast majority of chinese, romanian, or unmarked bearings being junk. NSK, NTN, Koyo, Nachi, SKF, FAG, Timken, are all very good. If you can read off the bearing code from the existing bearing, the local industrial bearing supplier can usually match it well. Personally I do not pay more for OEM bearings when they are simply metric standard bearings - and I only re-use bearings when I don't care much about long term life.

David

glock37

Addicted to ArboristSite

I just wanted to say thanks to Randy for showing us how to install bearings

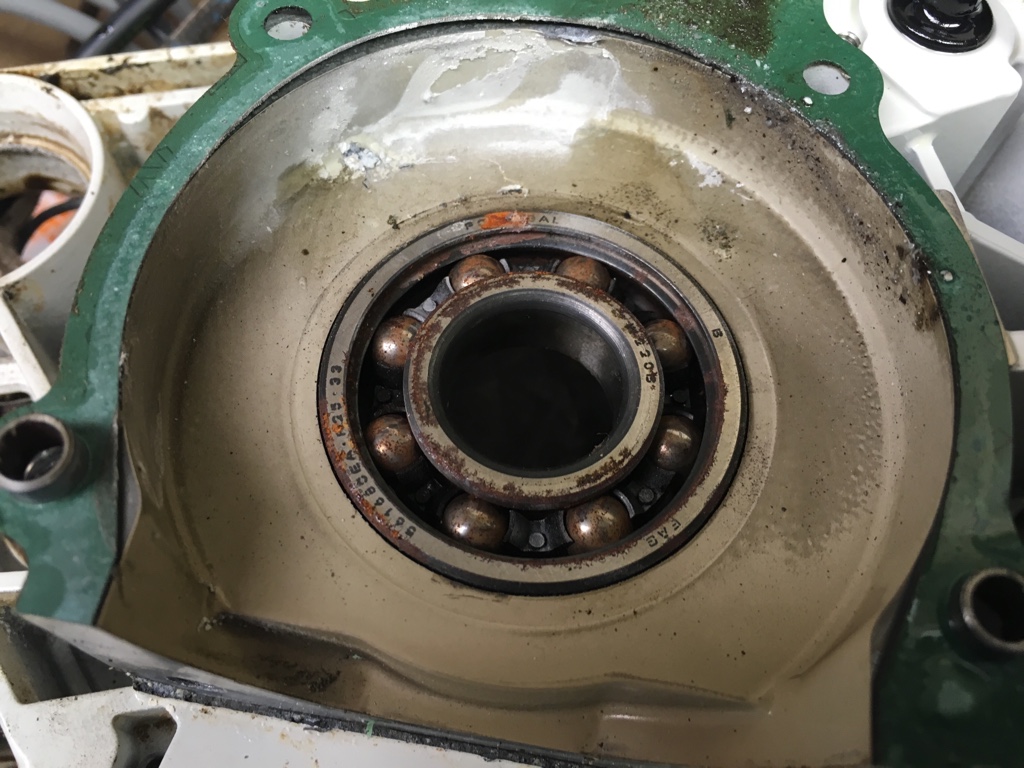

Just got done installing bearings in a MS 880 that had a bad rusted clutch side bearing

Heated case halves just like the thread both bearings dropped right in and only had to smack crank one time to free up once bolted tight

Mike

Just got done installing bearings in a MS 880 that had a bad rusted clutch side bearing

Heated case halves just like the thread both bearings dropped right in and only had to smack crank one time to free up once bolted tight

Mike

glock37

Addicted to ArboristSite

This is what i started with

Sent from my iPhone using Tapatalk

Mastermind

Work Saw Specialist

You are doing a lot of those big saws these day Mike. Many dealers I know have never even seen one. That puts you in the upper percentile.

glock37

Addicted to ArboristSite

I only do what the dealer doesnt have the time too do

Thanks

Sent from my iPhone using Tapatalk

Thanks

Sent from my iPhone using Tapatalk

Definitive Dave

wanna-be saw racer, saw hoarder, parts whore

- Joined

- Jul 27, 2013

- Messages

- 2,118

- Reaction score

- 5,086

crazy oil seal!!

glock37

Addicted to ArboristSite

I never seen a oil wear thru there how no idea the flange was still in bearing

You think because bearing was rusted ?

Sent from my iPad using Tapatalk

You think because bearing was rusted ?

Sent from my iPad using Tapatalk

Similar threads

- Replies

- 4

- Views

- 783

- Replies

- 27

- Views

- 3K

- Replies

- 0

- Views

- 273