dmitriy

ArboristSite Lurker

Mittysupply.com will have a carb.

I forget if there was a reason you can't just change the main jet instead of the whole carb? (I bought mine from mittysupply)

Mittysupply.com will have a carb.

How would you know it works like the Stihl. It's shaped like the Stihl. That is all we know besides it's cheaper. Does "no need", mean a wire was not included?Got the tach, no need for a coil wrap either!! (Seems to work same as the stihl one) A little 3M dual lock and it's on there. Gotta pick up the wrist pin / bearing and swap those & fuel cap plus put down some heat shielding

Why would you want to change the jet, you want to starve it of fuel. It can be changed. It's the right jet for this saw. Walbro wj76 Carb is ready to go after tuning.I forget if there was a reason you can't just change the main jet instead of the whole carb? (I bought mine from mittysupply)

How would you know it works like the Stihl. It's shaped like the Stihl. That is all we know besides it's cheaper. Does "no need", mean a wire was not included?

Why would you want to change the jet, you want to starve it of fuel. It can be changed. It's the right jet for this saw. Walbro wj76 Carb is ready to go after tuning.

Only difference in 67 or 69 is the jet size. Delivering much less oil/fuel. Think of the carb as the engine oiler

You could definately sand it down so that the bar plate sits flat. And, it definitely has an "installation point" cast into the case like you said. Kinda looks to me like it would only serve a purpose if you didn't have the bar plate installed. There are a lot of saws that don't have the plate, but this particular saw really needs the plate to encapsulate the tensioner guts.On back William Prophet mentioned we should be mindful of the nylon bumper behind the bar plate lifting it off the case and causing a mess and less oil on the chain.

I was putting my new rim kit and as it sat on the bench I saw the bumper behind it. Now I installed it. It did lift it up slightly.

So I think what it is, it is suppose to be there, it's just that the aftermarket is slightly thicker. I will test that theory with a oem and see if it lays flat.

Devil is the the details, I was holding saw so you don't see the slight gap but it's there

While I hear what you're saying, if a person wants to build a saw that functions properly, you just don't "put it in because there is one on an OEM Stihl" if it doesn't work. The nylon guide is too thick to let the plate seat. You need to figure out how to deal with it. I don't really care "how" you do it, but the plate needs to sit flat against the case or bar oil won't all go into the bar. So "to each his own", but all my saws function perfectly. All my saws are "work saws" and that's not just the 660 clones. These aren't "play saws" or "ebay sale" saws. If you want the oiler to put the oil in the bar, the plate needs to seat around the oil journal with no gaps.... The engineering behind a nylon chain guide is such that it can rub/guide the chain without damaging the chain and not allowing the chain to damage the case. This nylon guide is not in a position to do that with the plate installed.I am a kit builder and I adhere strictly to Stihl practice adjusted for differences created by it being a copy. Example, bad advice to use a 17 squish on an Farmertec cylinder, not because of the cylinder but because of the main bearing under it. So it's easy, very easy, to get bad advice on our kits on a wide range of matters. Not that the advice is untrue with a original saw. But that's not what we are building. So when they indicate something I go along with it. I am not, nor should anybody else try and reinvent the chainsaw. We have a road map. It's best to follow it.

I installed it because on every edition of the 066 or 660 that I have paperwork on and I think I have them all, there was a bar plate and it looked to support the plate from underneath. Actually shielding the nylon stop.

So now I wonder if the nylon piece interfered simply by being thicker. And that is precisely what makes this so much fun. Yes you can cut it, sand it, pound it. But you have to compare it to an oem first to determine if it is in fact the cause.

Or you can just slap it together and never look at it closely. I fall in the look at it closely camp. Know and understand. The case is one of their better reproductions. Only one maybe two flaws so far. The chain adjuster which was a major screwup and maybe the locator pin exit hole (maybe that was on the 440 only)

We will see.

"Hurt my feelings"? Are you brain damaged? I'm agreeing with you. I don't care how you fix it, it needs to be fixed. Christ, the other day you were telling some guy on here that "problems need to be fixed and that's what the kit is about. So, what would be your suggestion as to fix it? So far, all your answers are "throw some more OEM parts in it"... These guys are looking for a functional/cheap saw... At some point, it's gonna cost more to complete the saw than it costs Stihl. You would buy an OEM nylon chain guide over a few thousandths of an inch, when you could just rub it on a piece of sandpaper a couple times or just leave it out!? Man bro, you really need to chill. I know this is "your" thread, but I thought we were trying to all get together to solve potential problems...Well bless your little heart. I hate I hurt your feelings. Really.

Attached are photos of a FarmerTec nylon guide and a Stihl one. For everyone else but William notice the thickness. The huztl is thicker and would push the plate up. The Stihl nylon would still support the metal plate but not lift it.

chainsaw kits and packing lists

http://thechainsawkitguy.com

http://YouTube.com/c/the1chainsawguy

Did you get your kit yet?Hey guys, Iam new here, been reading up getting ready for my 660 build if it ever gets here. appreciate all the info that has been posted on this kit, should make things go alot smoother.

I have been a auto tech for 20+ so not scared of a little chiansaw, it aint no Cadillac. But I have never been above asking for help if I have needed it. So Iam glad u guys are here helping people out.

I wouldnt mind having a repair manual to read through while iam waiting for my kit if anyone could send me one that would be great. Iam not into making videos but I will post what problems I encounter,

and how long it takes to blow it up. lol I will be running the piss out of it!

I have been reading post from the anti clone crowd, and I have no dog in that fight, I hated watching auto parts go down hill over the years as us companys went under and more lesser quality overseas parts

flowed in. I felt like my work ended up of lesser quality because of the parts, and it made me pissed. nevertheless the world is just different now, and I bought a chinesse saw lol!

I am wondering though in one of atfleetguys videos he shows Husqvarnas anti vibration springs that he said they had in the 90,s and now stihl has the same spring setup. so if true that is a copy. How do you guys feel about that?

This is just the nature of buisness.

I bought one because I cut firewood and I like to tinker and play and for the price I dont care if it grenades. Iam too poor to grenade a 1200 dollar saw. Mike

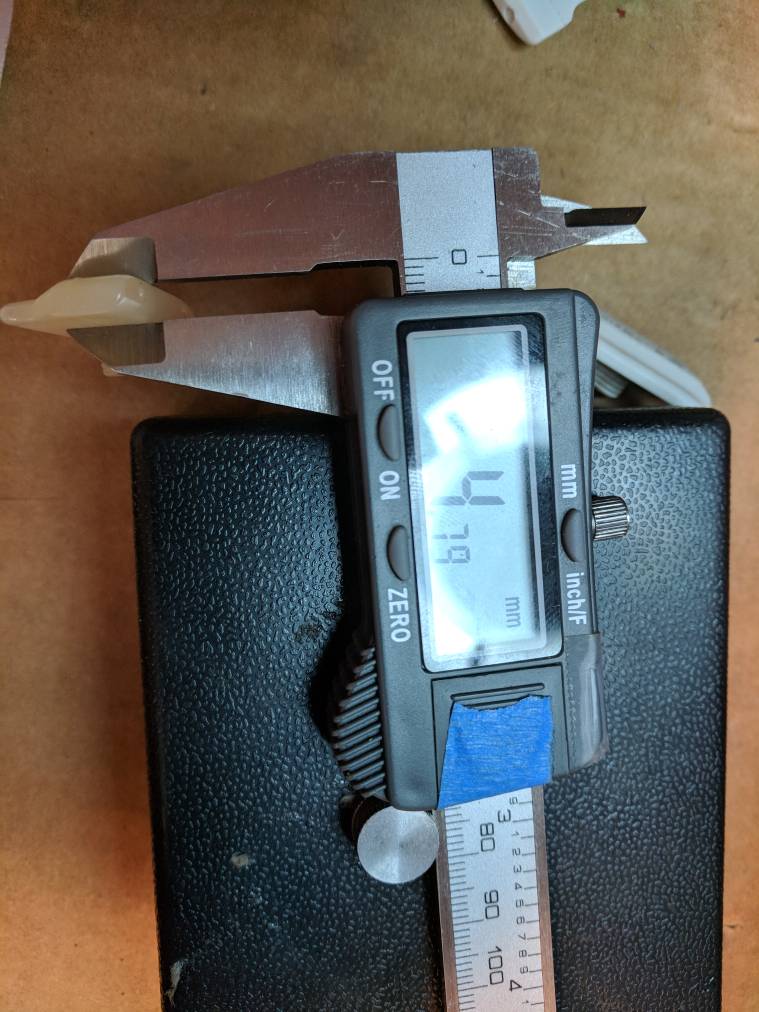

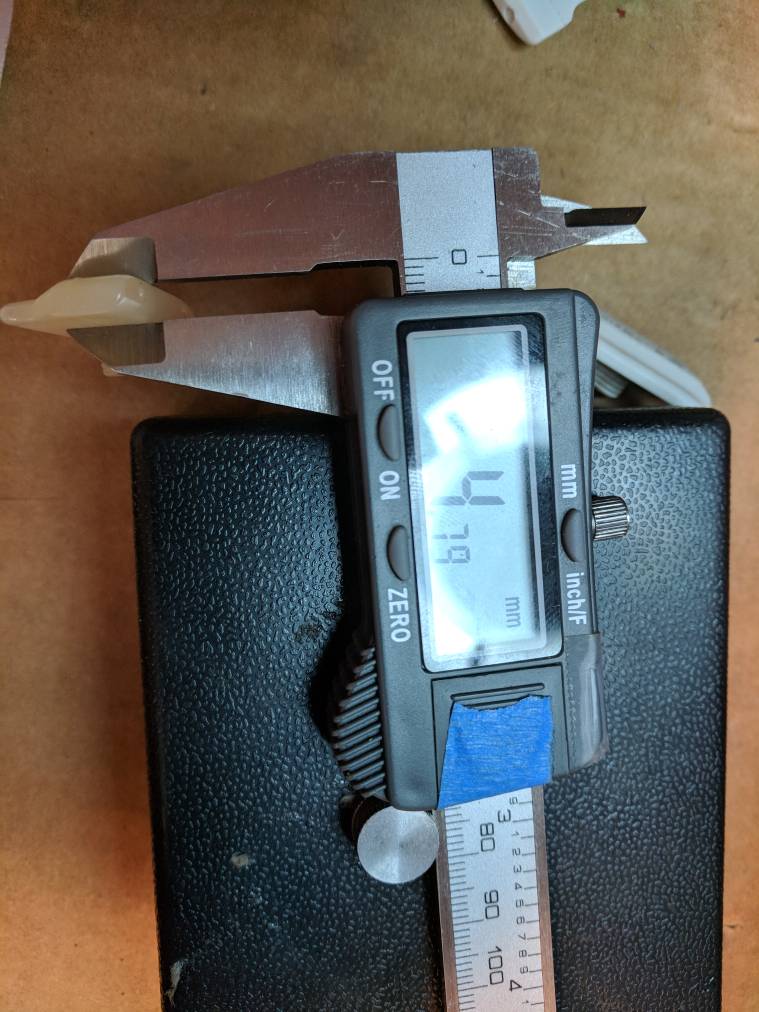

What are your port timing numbers with the gasket installed?Yeh I got it. Looks pretty good. Put the cylinder on last night with no gasket to check the squish and she hits the top and stops, measured the gasket .022

I havn't checked it with the gasket installed yet but with some rough measuring she looks to be tight boys!

Is there another company that makes a thicker gasket?

Wow, mine was .035 without a gasket. I didn't try it with it.Yeh I got it. Looks pretty good. Put the cylinder on last night with no gasket to check the squish and she hits the top and stops, measured the gasket .022

I havn't checked it with the gasket installed yet but with some rough measuring she looks to be tight boys!

Is there another company that makes a thicker gasket?

Wow, mine was .035 without a gasket. I didn't try it with it.

Sent from my Moto G (4) using Tapatalk

That is strange. Did your cylinder have a name on it? Mine had no name but was in a farmertec box. I was disappointed that I had .035 squish with NO gasket.Worked on the pig tonight, put it together with the gasket on, checked 4 spots had .024 on 2 and .025 on 2. So I put it together, thats strange everybody else is ok with no gasket.

cylinder looked pretty good maby somebody had a brain fart on mine. Almost done with it, had to order decomp plug so I can leak test it, probly be next week before I get that.

Case was really nice, bearings were smooth, seals looked and felt fine, gasket looked like a gasket, should be fine, brake spring was wrong, fuel cap came with a O ring installed,

sprocket has Stihl name on it, rubber parts look good to me, yeh they dont look and feel like stihl but they look like they will be just fine, throttle plate on carb looks like a big leaky toilet,

choke lever and trigger are garbage, it wont have a fast idle, plastic is nice looks like decent quality. I personally don't like that the screws came pre applied with loctite,

I didnt have any problems but fine threads tiny screws that dryed up crap can ball up and make them go in tight, just makes test fitting a pain in the ass, I prefer to apply my own.

Case went together like butter stuck crank in freezer heat gun case to almost 200 floped right in, prepared press stuck case half with crank in freezer

waved the heat gun around the case just fer a min it was a touch over 100 the case halves fell together with my hands to within a 1/4 inch finished in the press

and that took NO effort what so ever. could have lightly tapped it with hammer and socket and seated it.

I know some of you already know this stuff, Iam just telling my thoughts about the kit. Mike

That is strange. Did your cylinder have a name on it? Mine had no name but was in a farmertec box. I was disappointed that I had .035 squish with NO gasket.

I just started on the 365/372 kit and its the same way. .032 .033 .035 .036 with NO gasket. I don't think I will be buying anymore of these kits.

Sent from my Moto G (4) using Tapatalk

Enter your email address to join: