Derf

Addicted to ArboristSite

Tore down a saw, noticed the wrist pin was pretty tight coming out. When I got it out it was galled with marks.

I've heard that you can turn them down in a lathe with 400, 600 and 1200 grit Emory paper, but I don't have a lathe. Looks like you can't buy a new wrist pin either, likely because they are matched to the piston. So you buy a whole piston assembly for a new wrist pin.

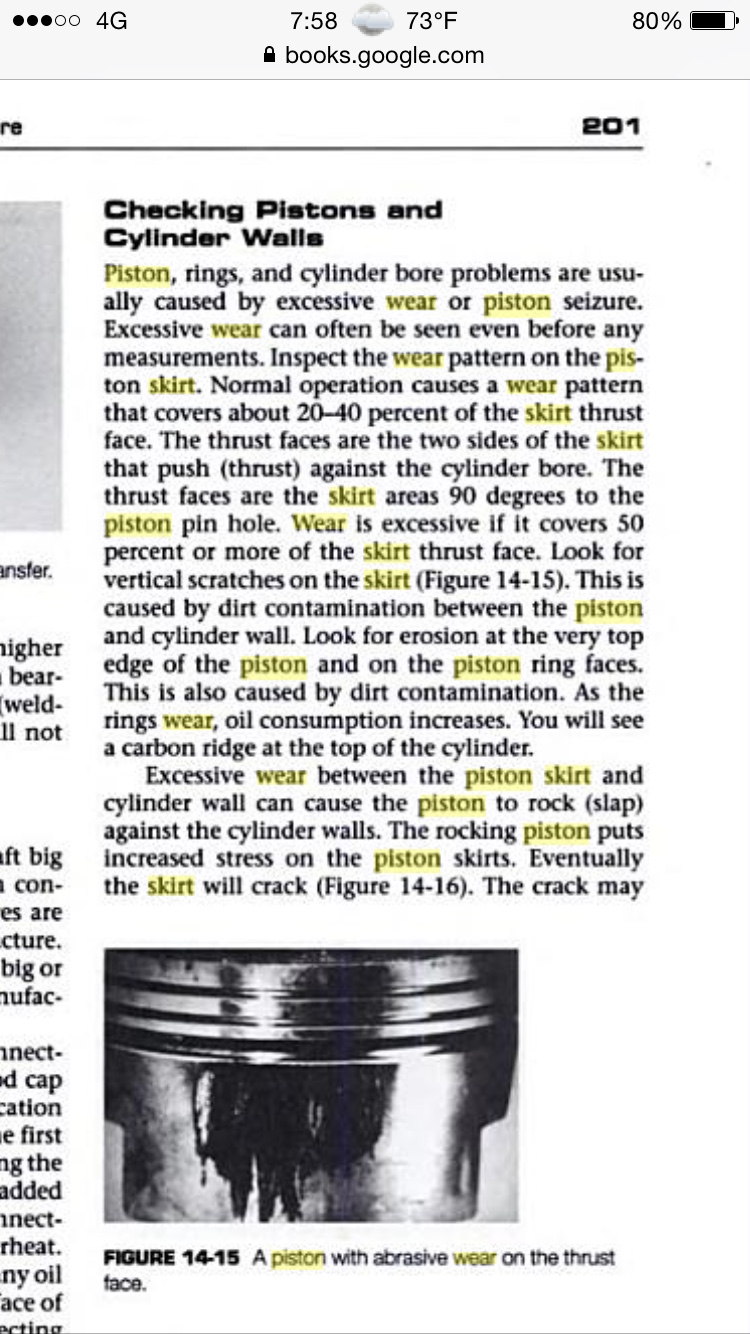

Here's my piston. No scoring, just some carbon build-up. The machine marks are gone from the piston skirt. I don't know how many hours are on this used saw, it looks like the original parts from a 6-year old saw.

Probably the next question is what's the ring gap? Well I don't have my feeler gauges. So how's the compression you ask? My gauge says 148psi on a stock 346xp.

So I ask, does anyone replace a ring with a used piston or do you do rings and Pistons together do to wear on the side skirt? Should I be worried about the tight/discolored wrist pin? Is it time for a new piston kit? Or do people only replace Pistons when they get scored? And if so, how are the meteor kits at $38 compared to OEM Mahle for $56?

I've heard that you can turn them down in a lathe with 400, 600 and 1200 grit Emory paper, but I don't have a lathe. Looks like you can't buy a new wrist pin either, likely because they are matched to the piston. So you buy a whole piston assembly for a new wrist pin.

Here's my piston. No scoring, just some carbon build-up. The machine marks are gone from the piston skirt. I don't know how many hours are on this used saw, it looks like the original parts from a 6-year old saw.

Probably the next question is what's the ring gap? Well I don't have my feeler gauges. So how's the compression you ask? My gauge says 148psi on a stock 346xp.

So I ask, does anyone replace a ring with a used piston or do you do rings and Pistons together do to wear on the side skirt? Should I be worried about the tight/discolored wrist pin? Is it time for a new piston kit? Or do people only replace Pistons when they get scored? And if so, how are the meteor kits at $38 compared to OEM Mahle for $56?