Man, did this thread go south. Sorry to see that.I once had a friend that did that with women.....

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New chain vs sharpened.

- Thread starter Doug M

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Apr 28, 2014

- Messages

- 7,785

- Reaction score

- 10,430

I guess I’m the silly one being a faller it’s not uncommon to throw a brand new chain on the grinder get it dead on like all the others, but hey what do I know just a silly old cutter.

Sent from my iPhone using Tapatalk

Dead on? Waz that is?

Of course "they" (the guys that know what they are doing) do. It is done in between the muffler mod and removing the limiter caps from the Carb. And of course getting rid of the very restrictive spark arrester?

I've never 'modded' any saw I've ever owned, in any fashion - Never got into that. For me they're chainsaws, not race cars - and best left OEM stock for durability.

For the guys that do get into modding, nothing wrong with that either. It's a hobby, they enjoy it, and it is kinda interesting to hear what gains they achieve.

But I have cut a LOT of timber in my life time, and hand sharpened a lot of chains - on-site in the woods - with no gadgets or grinding wheels necessary.

Just a log or a stump to sit the saw on - hunker down over it with a file, and 5 -10 minutes later, back to work with a VERY sharp chain.

Oh ..... and YES - sharper than it was when it first came out of the box new.

I've never 'modded' any saw I've ever owned, in any fashion - Never got into that. For me they're chainsaws, not race cars - and best left OEM stock for durability.

For the guys that do get into modding, nothing wrong with that either. It's a hobby, they enjoy it, and it is kinda interesting to hear what gains they achieve.

But I have cut a LOT of timber in my life time, and hand sharpened a lot of chains - on-site in the woods - with no gadgets or grinding wheels necessary.

Just a log or a stump to sit the saw on - hunker down over it with a file, and 5 -10 minutes later, back to work with a VERY sharp chain.

Oh ..... and YES - sharper than it was when it first came out of the box new.

The manufacturers put a LOT of Money into R&D, all my saws are stock too, when I was ATVing, we left our Quads pretty much stock, I watched guys mod their quads, Especially the Banshees, the were in the Parking Lot, a LOT working on them. Out on the Flats, when they were running, they would go like raped apes, all High RPM, get them in the side hills where you had to work the throttle, they were Phucked, great while WOT, let OFF the throttle then come back on, and they just fell on their faces. There were lots of places the hopped up 2 cylinder 350cc Banshees Couldn't follow us on our Stock Honda 250R's, simply too narrow of a power band.

I don't fault anyone either for Enjoying the Challenge of seeing just what they can get out of their saw, or whatever, their tool, their Budget, their Fun.

I Enjoy wood cutting, but it is also our Primary way of heating our home, we have a Forced Air Electric Furnace, but that is a real Budget Buster, so my saws earn their keep, and I look at them as a Tool, where some also see them as a toy, just not how I use mine.

Doug

- Joined

- Apr 28, 2014

- Messages

- 7,785

- Reaction score

- 10,430

Oh ..... and YES - sharper than it was when it first came out of the box new.

Sounds like a dubious claim but lets see the proof/videos, factory vs your hand filed chains.

Define 'sharper'.

Not being a smart*ss, but how do you define it? Speed of cut? Size of chips? How it feels when you rub your thumb past it? Measured bevel angles? How long the edges last?

We get into these p*ssing matches about 'sharpness' and may not even be talking about the same thing.

Some guys use appearance. Some use performance criteria. I am always interested in practical, objective, ways to compare, preferably at the bench, where I do most of my sharpening.

I believe you; just curious how you measure or define it.

Maybe I am looking for a unicorn . . .

Philbert

Not being a smart*ss, but how do you define it? Speed of cut? Size of chips? How it feels when you rub your thumb past it? Measured bevel angles? How long the edges last?

We get into these p*ssing matches about 'sharpness' and may not even be talking about the same thing.

Some guys use appearance. Some use performance criteria. I am always interested in practical, objective, ways to compare, preferably at the bench, where I do most of my sharpening.

I believe you; just curious how you measure or define it.

Maybe I am looking for a unicorn . . .

Philbert

Skeans

Addicted to ArboristSite

Define 'sharper'.

Not being a smart*ss, but how do you define it? Speed of cut? Size of chips? How it feels when you rub your thumb past it? Measured bevel angles? How long the edges last?

We get into these p*ssing matches about 'sharpness' and may not even be talking about the same thing.

Some guys use appearance. Some use performance criteria. I am always interested in practical, objective, ways to compare, preferably at the bench, where I do most of my sharpening.

I believe you; just curious how you measure or define it.

Maybe I am looking for a unicorn . . .

Philbert

I’ll throw one out here to just start it out, self feeding, there’s a feel I go for well cutting to help not make a day any longer then it needs to be.

Sent from my iPhone using Tapatalk

I’ll throw one out here to just start it out, self feeding, there’s a feel I go for well cutting to help not make a day any longer then it needs to be.

Sent from my iPhone using Tapatalk

That’s for sure. Good filed or square ground is worlds ahead of new chain. If I had to use all new chain I’d probably cut wood with all semi chisel since I’d expect it to be slow

If you really want to know how well you sharpen start milling where you touch up every other cut in hardwoods 20-30” wide. It can make milling go from fun to a miserable job.

Define 'sharper'.

Not being a smart*ss, but how do you define it? Speed of cut? Size of chips? How it feels when you rub your thumb past it? Measured bevel angles? How long the edges last?

We get into these p*ssing matches about 'sharpness' and may not even be talking about the same thing.

Some guys use appearance. Some use performance criteria. I am always interested in practical, objective, ways to compare, preferably at the bench, where I do most of my sharpening.

I believe you; just curious how you measure or define it.

Maybe I am looking for a unicorn . . .

Philbert

Simply the 'Cutting Performance' of the chain. There's no mystery to it - If the chain CUTS better, it's sharper.

Looks and Feel of the cutters mean nothing - nor does feeling warm and fuzzy about putting on a brand new chain.

Did I ever go so far as to sharpen a Brand new chain 'before' putting it on - Nope never went that far - Besides my filing is always done 'on the saw' and where ever I'm cutting.

But by the time I fell and limbed the first snig of logs after installing a new chain - I would stop and give it a light filing just to make it 'REALLY' cut.

And no, that wasn't done by filing the rakers all to hell just to make it aggressive. I normally don't hit the rakers much until about the 3rd filing, and if cutting mostly hard woods, don't go very aggressive at all.

When you're used to a good hand sharpened chain - and then you install a new chain - it almost feels like a semi-dull chain - that is until you file it.

No Unicorns - A properly hand filed chain, will simply perform ie: CUT, better than an out of the box or grinder sharpened chain.

The op's title was: NEW chain vs FILED chain. - His logger buddies were correct in what they told him - and I'm simply giving him my opinion too - FILED Doug.

Addendum - I'm only discussing 'round ground' chain. I've never used or had any experience with Square ground. It never gained any popularity in my neck of the woods.

Sounds like a dubious claim but lets see the proof/videos, factory vs your hand filed chains.

I have nothing to prove - Get yourself a file, stick with it and become a believer - or stick to your 'factory' sharp chains. Your choice.

But the file will set you free brother

Few years back. Run on stock 3120

The first chain we ran was a totally stock 60 driver oregon chain bought at the local co-op. the average time for 3 cuts was 2.89. Oregon LGX

Chain A 2.47 2.28 2.40 average 2.38

Chain B 2.50 2.57 2.31 2.48

Chain C 2.94 2.65 2.56 2.71

Chain D 2.53 2.54 2.35 2.47

Chain E 3.03 2.50 2.65 2.72

Chain F 2.72 2.66 2.91 2.76

Chain G 2.71 2.63 2.40 2.58

Chain H 2.75 3.06 2.81 2.87

Chain I 2.66 2.59 2.47 2.57

[/quote]

The first chain we ran was a totally stock 60 driver oregon chain bought at the local co-op. the average time for 3 cuts was 2.89. Oregon LGX

Chain A 2.47 2.28 2.40 average 2.38

Chain B 2.50 2.57 2.31 2.48

Chain C 2.94 2.65 2.56 2.71

Chain D 2.53 2.54 2.35 2.47

Chain E 3.03 2.50 2.65 2.72

Chain F 2.72 2.66 2.91 2.76

Chain G 2.71 2.63 2.40 2.58

Chain H 2.75 3.06 2.81 2.87

Chain I 2.66 2.59 2.47 2.57

[/quote]

- Joined

- Dec 6, 2014

- Messages

- 21,153

- Reaction score

- 24,993

Burly Canadian men chase unicorns!!!????

- Joined

- Apr 28, 2014

- Messages

- 7,785

- Reaction score

- 10,430

I do believe. I grind and file when the chain becomes dull. It is not dull when brand new. At least not Stihl and Husky. If you are buying bulk chain from Estonia or Kinoshita or some other place then maybe you are dead on.

I have nothing to prove - Get yourself a file, stick with it and become a believer - or stick to your 'factory' sharp chains. Your choice.

But the file will set you free brother

[/QUOTE]Few years back. Run on stock 3120

The first chain we ran was a totally stock 60 driver oregon chain bought at the local co-op. the average time for 3 cuts was 2.89. Oregon LGX

Chain A 2.47 2.28 2.40 average 2.38

Chain B 2.50 2.57 2.31 2.48

Chain C 2.94 2.65 2.56 2.71

Chain D 2.53 2.54 2.35 2.47

Chain E 3.03 2.50 2.65 2.72

Chain F 2.72 2.66 2.91 2.76

Chain G 2.71 2.63 2.40 2.58

Chain H 2.75 3.06 2.81 2.87

Chain I 2.66 2.59 2.47 2.57

What were the rest of the chains. Not that much difference in any of them. Steve

What were the rest of the chains. Not that much difference in any of them. Steve[/QUOTE]

Mostly Oregon and Carlton best I remember. The threads are on chainsaw repair. Most were race chains of the sort. There’s been several chain builds done through the last few years. Stock chain does good in some and others it’s not even close.

Skeans

Addicted to ArboristSite

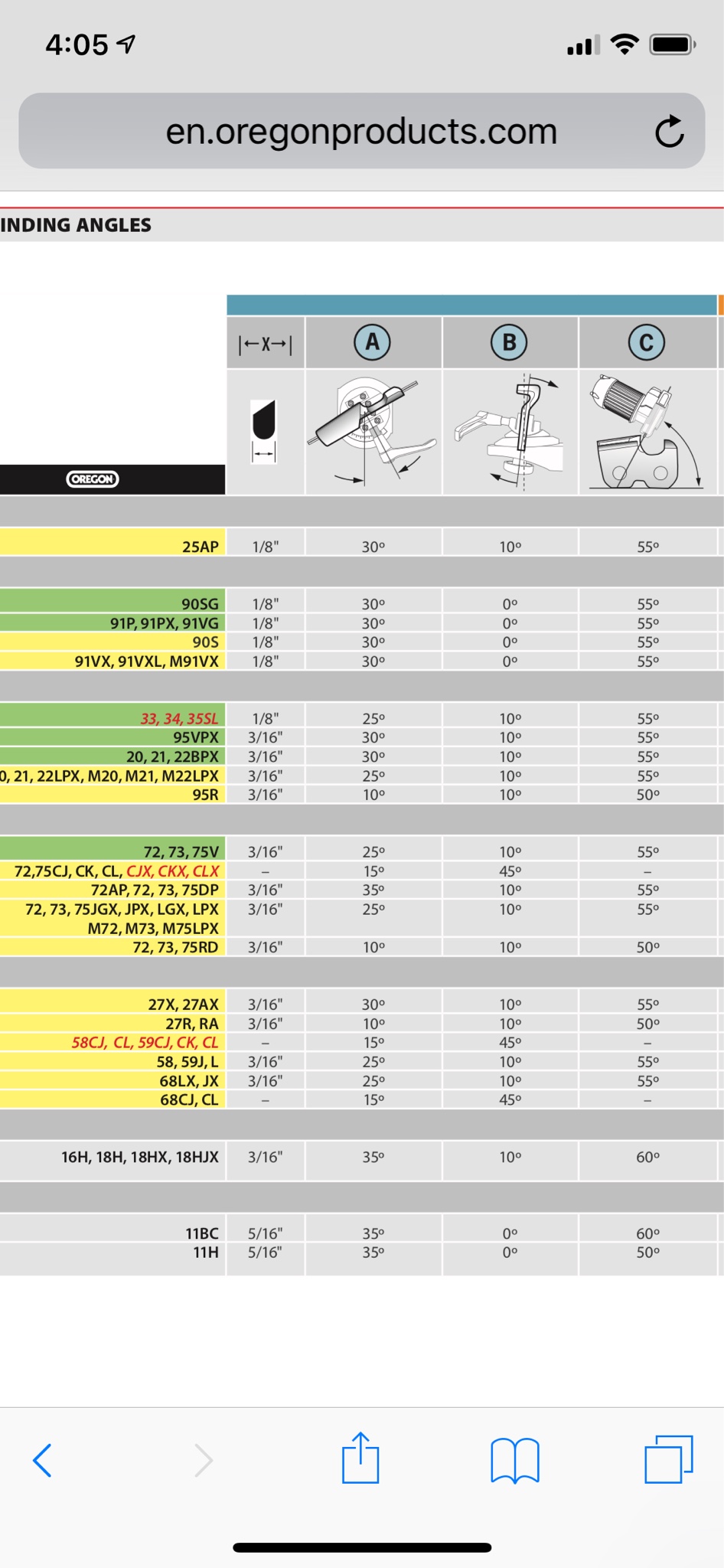

VS the angles I use

There’s one reason stock out of the box will get tossed on the grinder right off the bat besides the rakers getting done.

Sent from my iPhone using Tapatalk

A properly filed chain set up for the wood one is cutting that day will relieve a lot of physical stress , not having to apply force to the top handle or dig dogs in and pry a saw through the wood. Many of my saws have the dogs removed as I don`t and many of my friends do not use them on our saws but replace them with a smooth slide/guide or whatever one wants to call them. The chain applies how much feed force it can handle in hard or soft wood. My arms and shoulders really appreciate a nice sharp self feeding chain.

A well set up chain almost defines ones cutting experience. Not only is a properly ground or filed chain fast, its smooth, its good to your saw components, its good to ones body & energy levels, its kind to the bar rails, sprocket & clutch drum. Learning the art is an investment in your experience every time you pick up a saw. For work chain, I'll use chain out of the box/off the reel but I'll run my eye over it first. Some new chain can look god awful out of the box, some looks/feels really nice. A 'sharp' chain don't necessarily perform well, the top plate, inner top plate angle or bevel and the side plate profile and angle must be good along with a raker height that suits the conditions. I still learn stuff about chain....& I done a few.

I would like to know the different ways to sharpen for a soft vs hard wood .

Sorry, I missed this earlier question. Companies that manufacture chains do a lot of research and testing on different species of wood. They measure the effect that a small change in the design of the cutter, or the sharpening angles, can make on speed, power demand, cutter life, etc.

But then they sell that chain to millions of users around the world, and have to pick general guidelines for 'all-around' use. If you are only cutting hardwoods, or only cutting softwoods, you may get better performance with different angles. It can even vary with the power of the saw that you are using.

No reason that you cannot have different chains ground or filed for different types of trees or cutting conditions. But if you want to stick to 'all-around' angles, the manufacturers' recommendations are a good place to start.

If you want to experiment, start with these top plate angles:

25° for hard or frozen wood;

30° for general use;

35° for softwood.

As noted, you can also use a more aggressive depth gauge setting with soft words, because they require less power to cut a larger chip.

Philbert

Similar threads

- Replies

- 61

- Views

- 5K

Latest posts

-

Want to Sell Husqvarna 338XPT, low compression, nice condition otherwise. 85$ plus shipping

- Latest: singinwoodwackr

-

-

-

-

-

-

Looking to get rid of a Poulan 655 In Great Condition message me if interested.

- Latest: danielmorris