Stumpys Customs

Stumpbroke

Now that the jug is done I'm gonna work on the cylinder base. I want to make it match the base of the jug to keep things flowing nice & smooth.

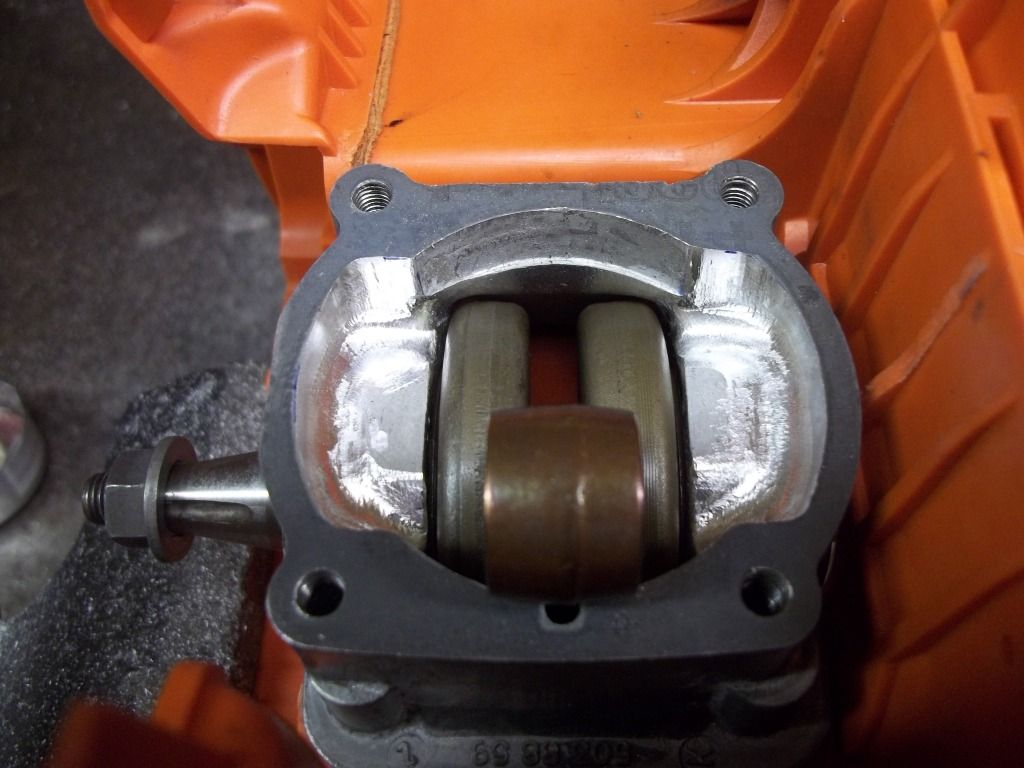

I removed some material that was in the way.

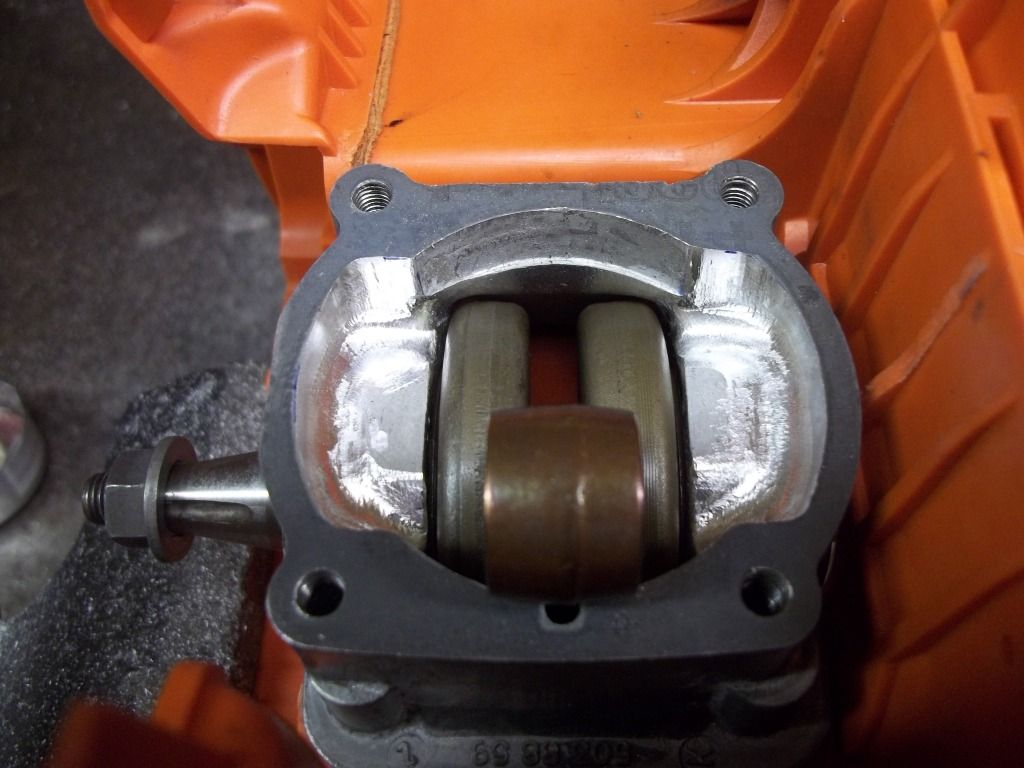

I removed some material that was in the way.

Last edited: