c5rulz

Addicted to ArboristSite

Well a round grinder square grinding chain?????????????????? I wish you the best and hats off you

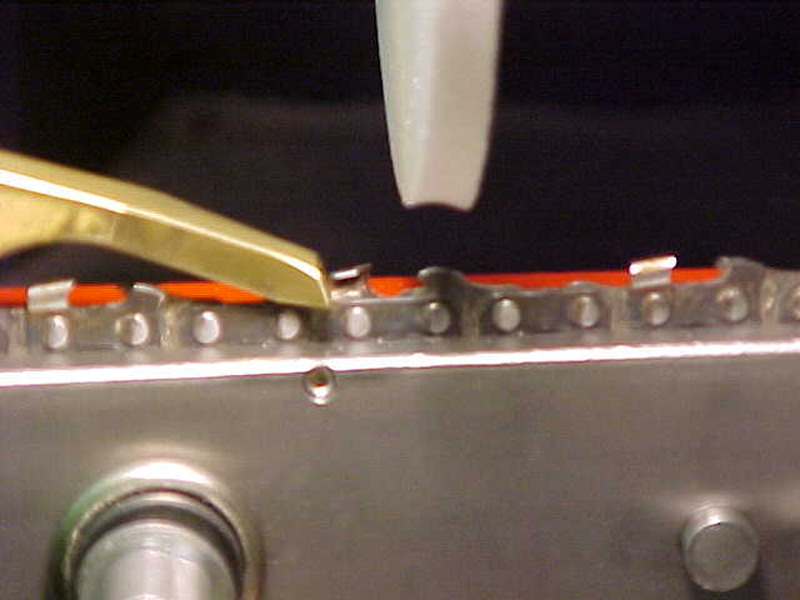

My apologies for the confusion, The Silvey 510 is for grinding round chain. My attempt with the Tecomec is to make the vice similar to the Silvey system for round chain.

I have thought about getting a square grinder but of what I cut is very dirty and chains often don't last a half a tank of fuel. Some say semi chisel for dirty wood but I don't care for it and use chisel.