Slamm

Addicted to ArboristSite

How those 441 cm compare to the 460 muffler modded vs muffler modded. I have a 576 auto tune husky and ive been using alot lately .I like it alot compared to the 460 s i have. i hardly use my 460 s 660s or 390 huskys anymore.

I don't know, the last 460 I ran was when I ran another guy's stock and ported 460 and they weren't that much more powerful than a mildly ported 441 and got horrible fuel mileage and had bad AV and air filter cleaning everyday, so I'm done with 460. Not saying they are a bad saw, but their time is over from a technological point of view.

In my opinion the 441 CM Muffler Modded is just a pure pleasure to work with, women and children can start them and while they may be a second or more slower in a full 28" bar of cutting, you will never notice it in the woods, as there are always vines to trip over and other such things that take up more than such minor time frames. That said, its not that much slower if it is in the first place, and it is a very comfortable saw to use, and therefore you can and will cut much longer than you will a 660 or 460.

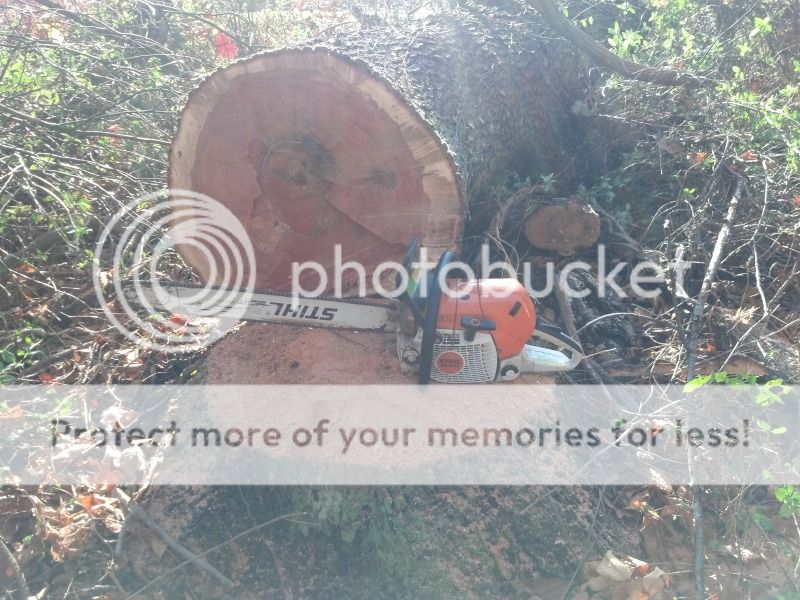

I have found the 441 platform to be tougher than the 460/660 rubber mounts, I have personally broken those rubber mounts with my hands and abuse pulling on the saw ........... to this date the only thing that has ever broken a 441 is trees falling on them. My first 441 was mildly ported and drank a large slug of water the day before I went over to Wiggleworth house and it never did run right from that date forward and had to end up putting a new carb on it, and I had a big bore kit that was ported run for 2 days of logging and then blew the top of the piston off. In my opinion none of those issues are the fault of the saw. Therefore in 5ish years of owning upwards of 6-8 and selling off 20 more, I don't know of one failure to run with them, and the warranty is in my name on most of those saws, so if there is an issue, I would know about it. I get no calls. The Stihl dealers that I have talked to about them say they sell them and then never hear from the operator again, because they don't have any issues with them.

The 441 CM is the same platform but has some computer brain thingy and it has performed flawlessly for me. Starts very easy usually 2 pulls is the max when cold and 1 pull all day long after that. When or if you run them out of gas, just put them on choke and 1 pull and let idle for 5 seconds while walking to the tree and they will keep on running, no more 20 pulls just to get it going again.

When I run a 441 CM with a muffler modd, I don't really care if porting could make them faster, I'm just really happy with them as is. I'm not against porting them and I will eventually when I can spare the time from them, but they are fast enough that I don't need faster, to make my money. Its like knowing the 461 is coming and it can be faster, but we know its not more comfortable to operate and it doesn't have Mtronic so I don't really care about that 461. Speed is only one "postive" going for that model, the 441 CM is no slouch in the speed and power department and has several other advantages that save time and effort daily.

Sam