tdi-rick

Addicted to ArboristSite

Yep, they're 1/8NPT thread.

I'm going to Tamworth tomorrow, was going to try and get something there.

All the gauges I have are quite a bit higher in scale than what I'm after too and I have a box full of gauges ranging from 2" diameter to 5" and up to several hundred psi but no low pressure ones.

Actually, i could pinch the boost gauge out of the Landy, it peaks at 15psi on the scale and the Landy is pushing 17psi ATM

I'm just about to press the discharge nozzle out of a carby too

I'm going to Tamworth tomorrow, was going to try and get something there.

All the gauges I have are quite a bit higher in scale than what I'm after too and I have a box full of gauges ranging from 2" diameter to 5" and up to several hundred psi but no low pressure ones.

Actually, i could pinch the boost gauge out of the Landy, it peaks at 15psi on the scale and the Landy is pushing 17psi ATM

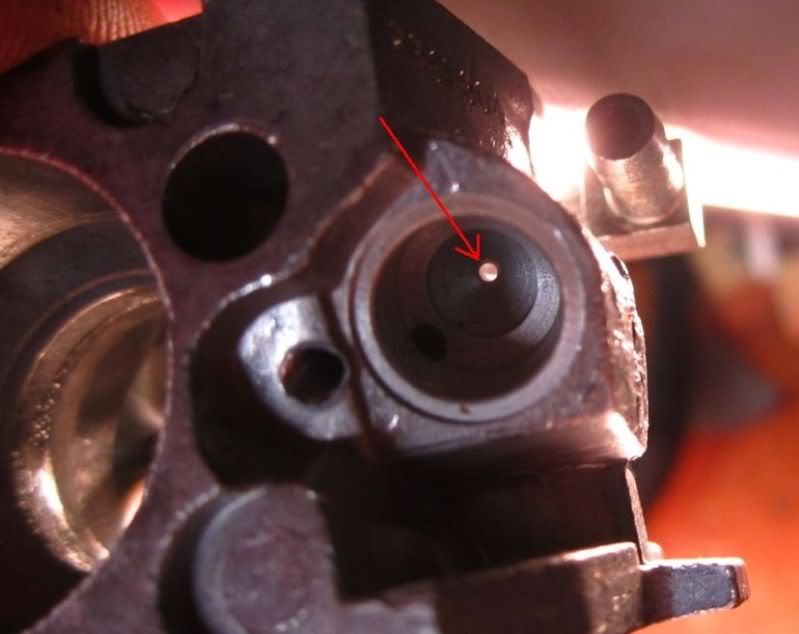

I'm just about to press the discharge nozzle out of a carby too