JoeB

ArboristSite Lurker

Thanks

Back when I was old enough to be around chain saws all we used was 24:1 or 32:1. I think 50:1 is just plain nuts.I run Belray H1R at 32:1 in every two stroke engine I own. The 50:1 bull **** is EPA crap.

Back when I was old enough to be around chain saws all we used was 24:1 or 32:1. I think 50:1 is just plain nuts.

So Randy are you going to use a new OEM crank or is there an aftermarket brand that you are comfortable enough to use?

Im just curious to hopefully save me troubles on future rebuilds. Thanks.

That was a fun game and a powerful message sent. Thanks Randy.

Oh, I've been running Belray H1R 32:1 since you told me about it a few months ago. Funny how engine failure threads turn into oil threads. I like oil threads.

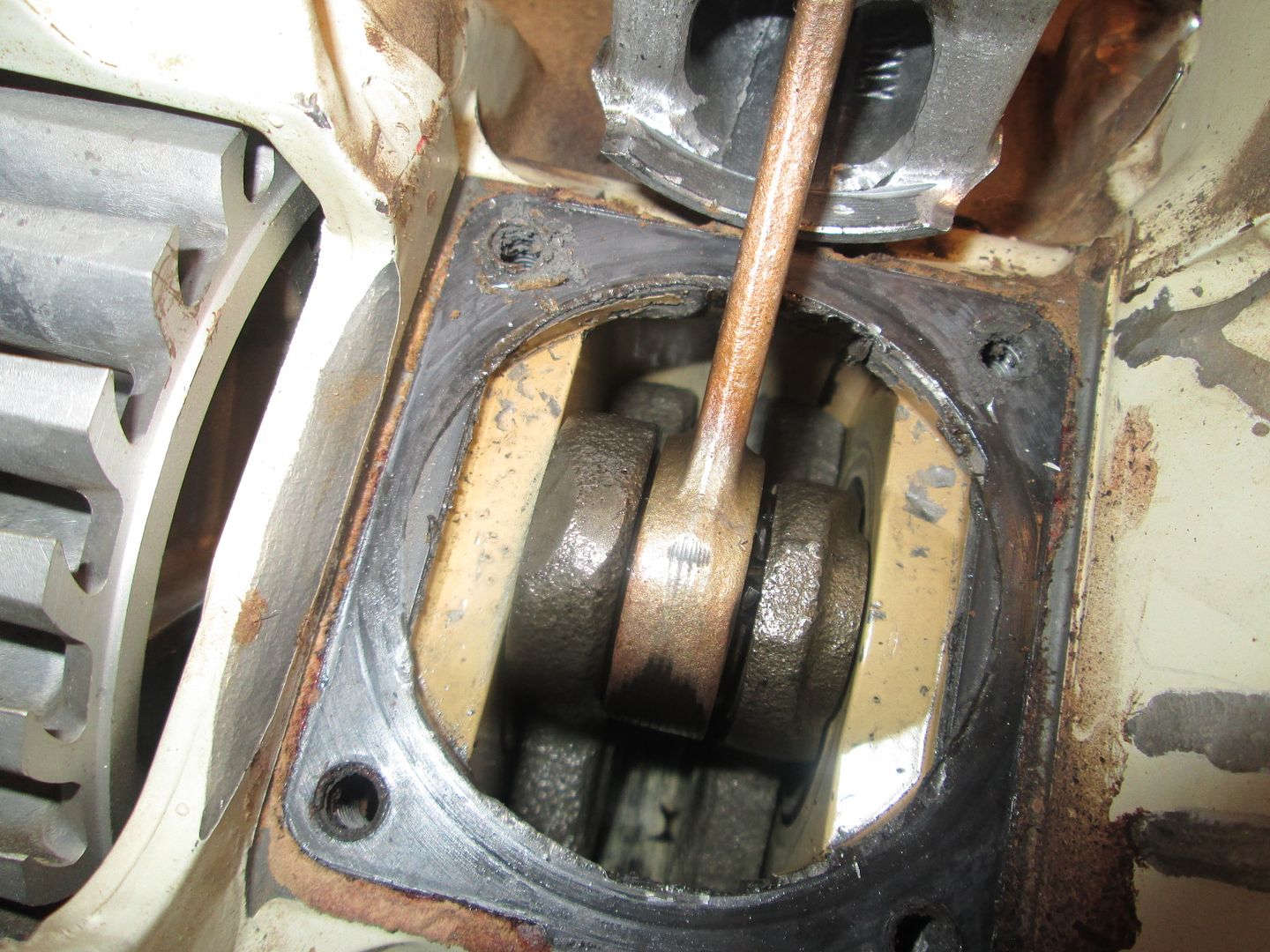

That has to be one of the first that I have seen to not score the piston but to break a rod bearing due to not enough oil.

Thank you for sharing this information, Randy. I've been running 40:1 with Stihl Ultra. I think it's time for me to switch.

Allegedly, particularly my beloved 385. I run straight diesel in it just to be safeAny of the saws benefit from 32-40:1. Huskies seem to be more prone to this than stihls.

Randy, you gettin kick backs from bel ray?

Looking at your pics on page one, in the third pic down, take a close look at the exhaust port roof. Also, notice the scuff on the exhaust side piston skirt, which started in the ring lands of the second pic. Agree it is a lubrication based failure, but I think as things began to tighten up the ring fracture and rpm energy had no where to go popping the bearing race. You would see heat discoloration on the bearing and connecting rod if there were skate problems prior to the failure.

Looking at your pics on page one, in the third pic down, take a close look at the exhaust port roof. Also, notice the scuff on the exhaust side piston skirt, which started in the ring lands of the second pic. Agree it is a lubrication based failure, but I think as things began to tighten up the ring fracture and rpm energy had no where to go popping the bearing race. You would see heat discoloration on the bearing and connecting rod if there were skate problems prior to the failure.

I had an unmodded 066 crank bearing let go. I have heard of others. Maybe a weak design point?

Just curious Randy, do you recommend 32:1 for stock saws too? Or better phrased, do you recommend 32:1 in saws that call for 50:1?

I've come to accept 50:1. Now you've got me wondering if its the best thing for my trimmers, blowers, etc. I'm thinking its all gonna get 40:1 anyway.

The thing that's funny about this is I know quite a few grass guys use Sabre at 80:1 and even 100:1 in string trimmers and blowers in the heat of summer. Some have for a decade. I realize the stresses of a trimmer and a chainsaw are very different. But blowers come a bit closer with the constant load and prolonged WOT.

Is the power produced by this ported saw simply consuming the available lube? Was it tuned way lean too? I'm not sure I understand. As dry as the bottom end of that looks, it makes me wonder how other machines can run that mix seemingly without issue?

Enter your email address to join: