Kingsley

ArboristSite Guru

That made my day! How cool. Thank you for sharing and well done video.

I can't wait to see it cut wood!

I can't wait to see it cut wood!

I finally put it in some wood again this weekend. This was the first since being torn back down for painting. It ran like a champ. The wood is Red Oak.

<object width="640" height="385"><param name="movie" value="http://www.youtube.com/v/M43Hrvd9xTk&hl=en_US&fs=1&rel=0"></param><param name="allowFullScreen" value="true"></param><param name="allowscriptaccess" value="always"></param><embed src="http://www.youtube.com/v/M43Hrvd9xTk&hl=en_US&fs=1&rel=0" type="application/x-shockwave-flash" allowscriptaccess="always" allowfullscreen="true" width="640" height="385"></embed></object>

Anyone know the solution for bad condensers on these 211's.

I replaced both coils on mine but still have intermitent spark.

Lee

Anyone know the solution for bad condensers on these 211's.

I replaced both coils on mine but still have intermitent spark.

Lee

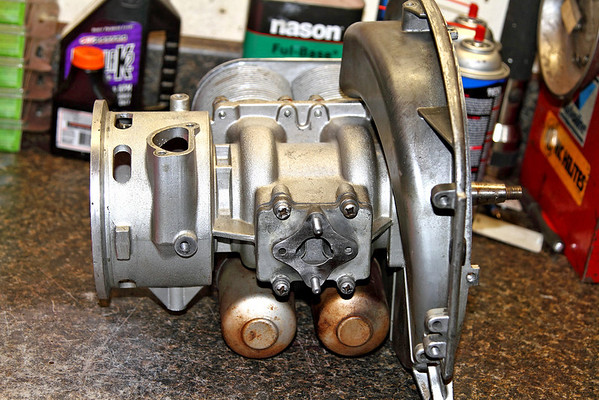

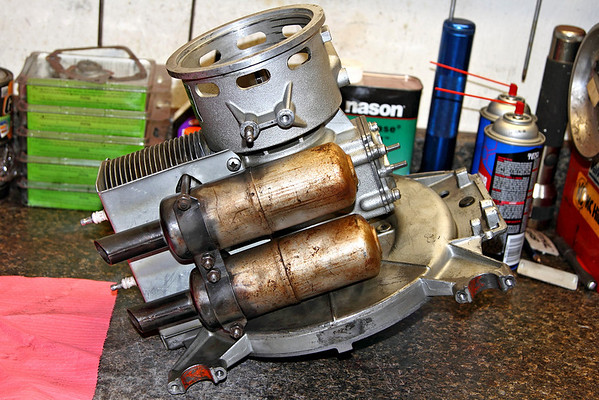

I agree Tim. I'm always impressed with Brad's attention to detail and his meticulous ways of doing things. I'm actually the one trading him a Mac 797 for a running DA-211. Hopefully I'll have time to post pics of it as I go.

I thought you were supposed to be trainingThis deal has been in the works for two years now. I've just been too burnt out to get back on these after doing the first one. They're a TON more work than a small modern saw, not to mention buried under piles of grit and grime.

You gonna post vids of that 797, right?

Enter your email address to join: