As far as the "Old huskies never die" thing, I can vouch for that. I'm finished making my potato salad now and the pics are uploadeed so here goes.

In order to continue with getting the firebox out of the furnace(can't really call it a furnace now tho) The paneling needs to be removed. I do not have pics of each panel coming off as they all come apart at once(atleast mine did) The plenum needs to be lifted to get the paneling off(only about an inch) to allow you to get the paneling out from under it. So however your plenums attach needs to be undone, mine were pop-riveted so I drilled them all out. There are 2 screws between the plenums on a panel that need to be removed before anything. I removed the side panel next, I think 6 screws hold it if my memory is right. the one that covers the side of the firebox. Once this one was removed all of the rest of them fell off. I left the rear panel there to help support the weight of the plenums but you can remove it as well as long as you secure the plenums. Here are a few different angles of the paneling removed.

and a section of paneling

So now all of the paneling is removed, now to drag the firebox out, HOLY*&$%^##%^&%$#@!$^(&%#%^$##%^&$# is it ever heavy, now onto operation lighten firebox.

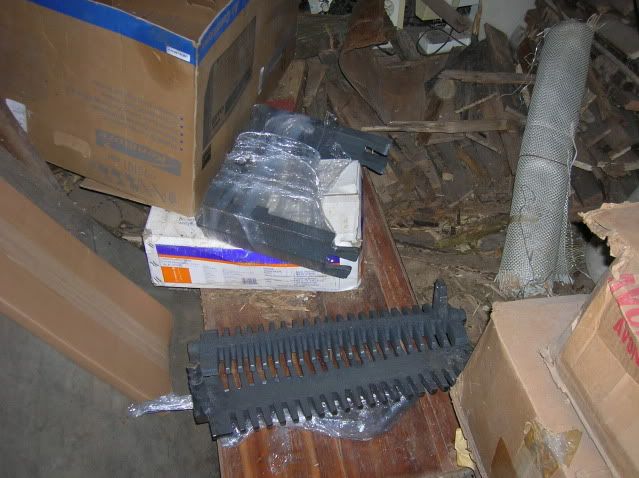

First thing I did was remove the shaker grates, most of these furnaces just had a stationary set of grates unless it was used for coal. In my opinion the shaker grates are awesome for shaking the ash thru to the pan as well. All of these furnaces should have been sold with shaker grates. the shaker grates just lift up and slide out the door, they have to be removed in a pair as there is a bar that hooks then together. I had to turn mine diagonal to get them thru, careful as they are heavy.

The grates next to the ash pan

Once the grates are out you can remove the frame for the grates, in theory it just lifts out and pivots at the center, mine needed a little help to do this action but they do come out. Be careful as I think they are only cast-iron and will break easy(mine didn't)especially if hit with a hammer, just use a little finess and a pry-bar and they will come out.

The frame(2 pieces stacked on top of each other.