What a coincidence!! I was working with bushings too!

Mine were a tad bigger...

The bushing(a bearing sleeve actually), is the silver ring in the small diameter. Small is relative though. The bushing OD is 11.500", and the ID is 10.621" Nailed the ID size at .0005" over the minimum..

Didn't want to kill it as there was better than 10 hours worth of work in it before I finish bored it. Monster 16oz. added for scale.

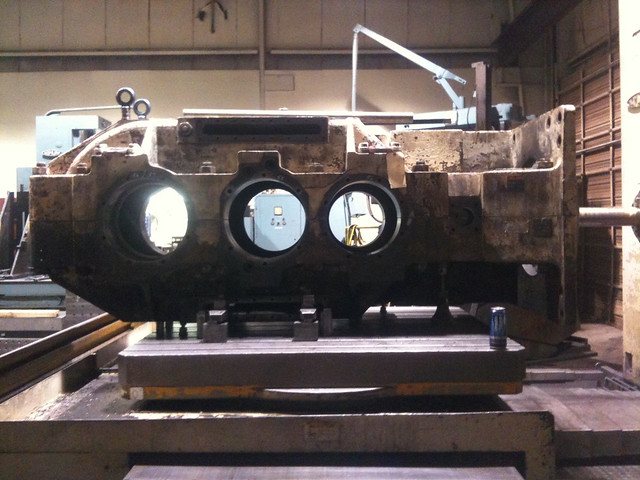

The bushing is on the input side of a gearcase used to drive a longwall conveyor. A 700HP electric motor plugs into this end. The project also involved truing all the critical surfaces on the input side. Cast Iron.

As you can see, the case isn't small. The setup is tough as all four bore centerlines must be lined up to within .002". Just another day of running a Horizontal Boring Mill...

A short clip of a longwall shear in operation. The coal it is cutting is falling onto the conveyor.

.