Mastermind

Work Saw Specialist

Another member's saw.......he just had a feeling something wasn't quite right. Plus it was starting to score the piston a little.

It's the one on the left........looks like a nice 372XP.

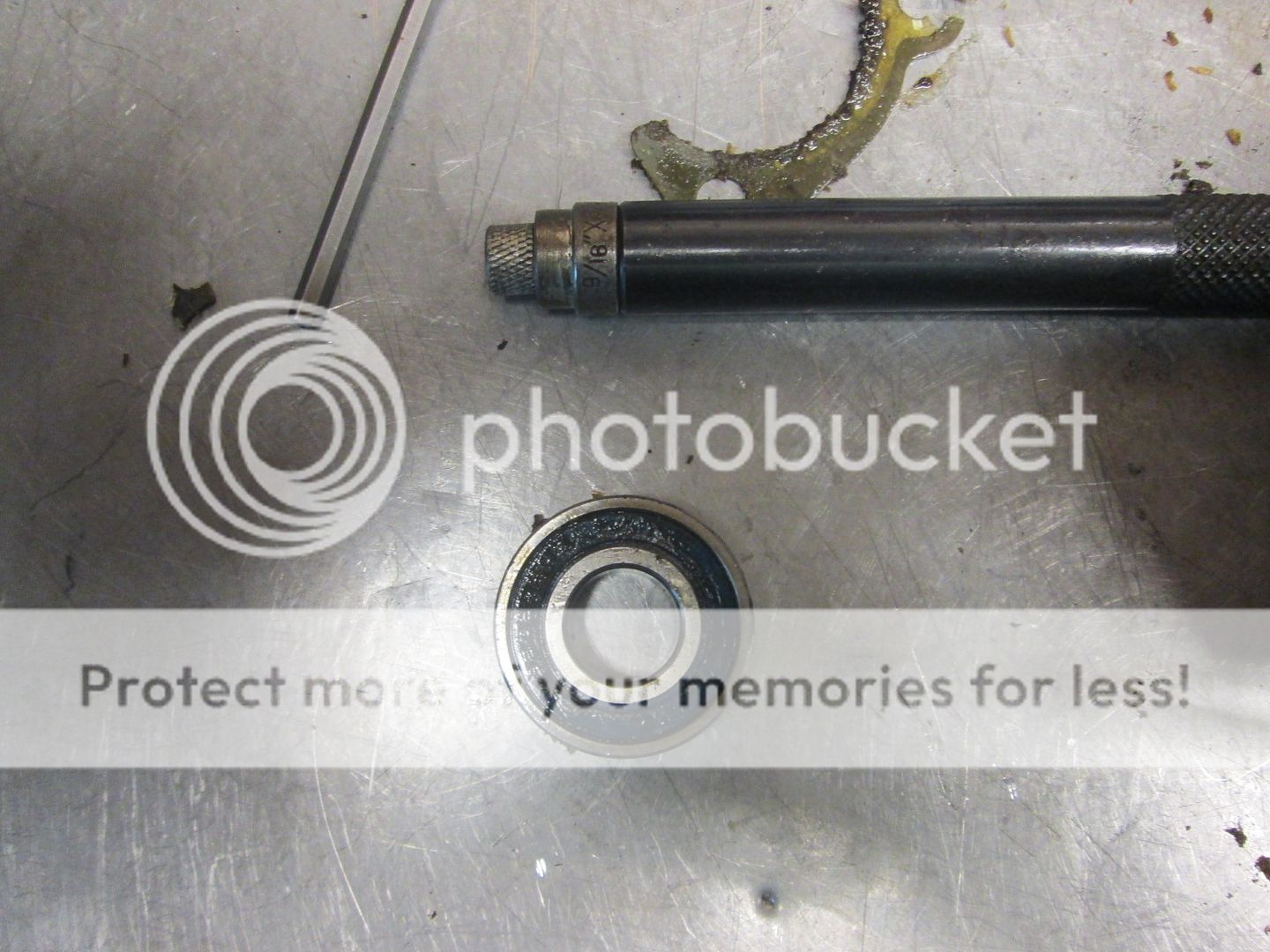

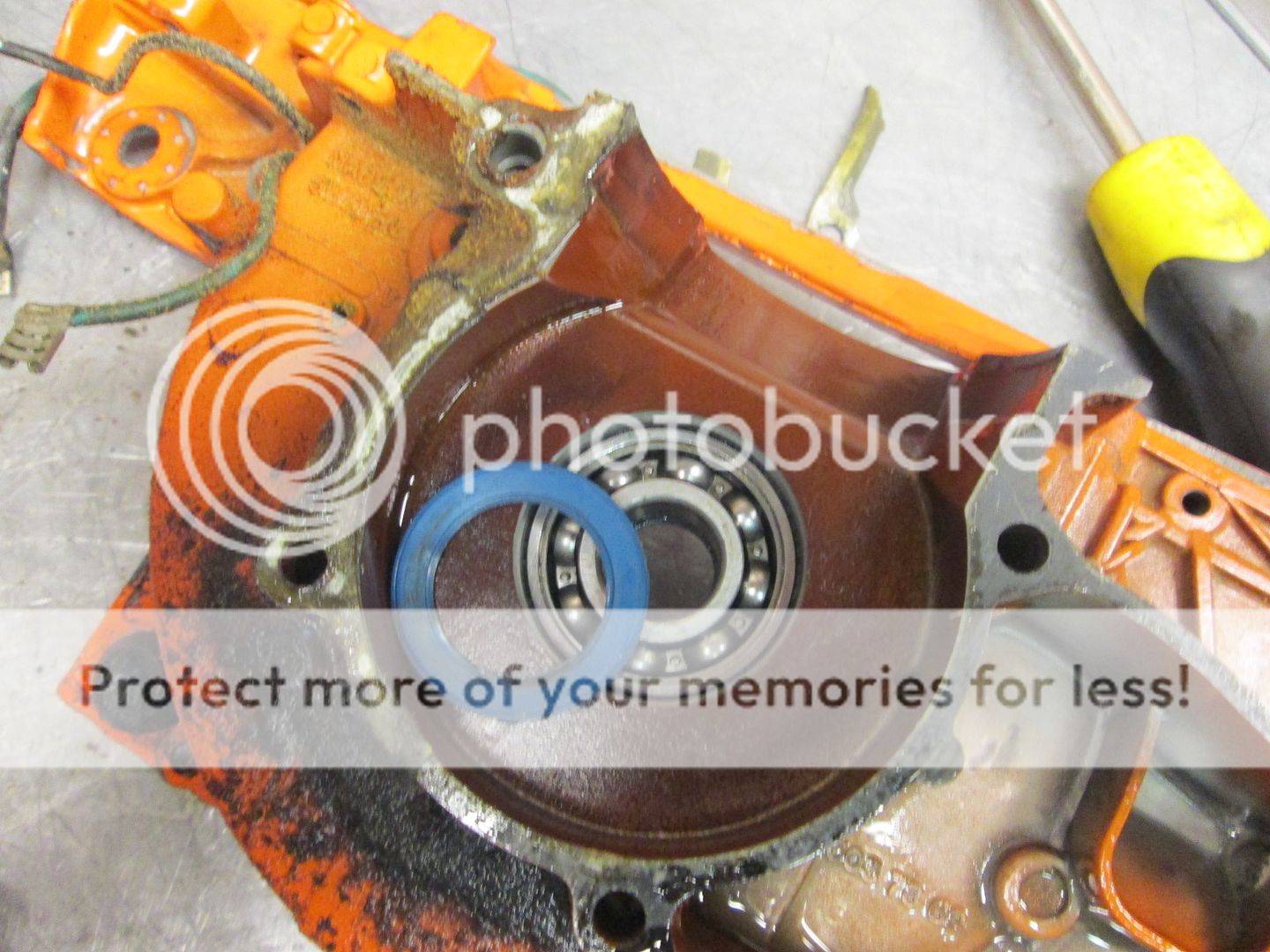

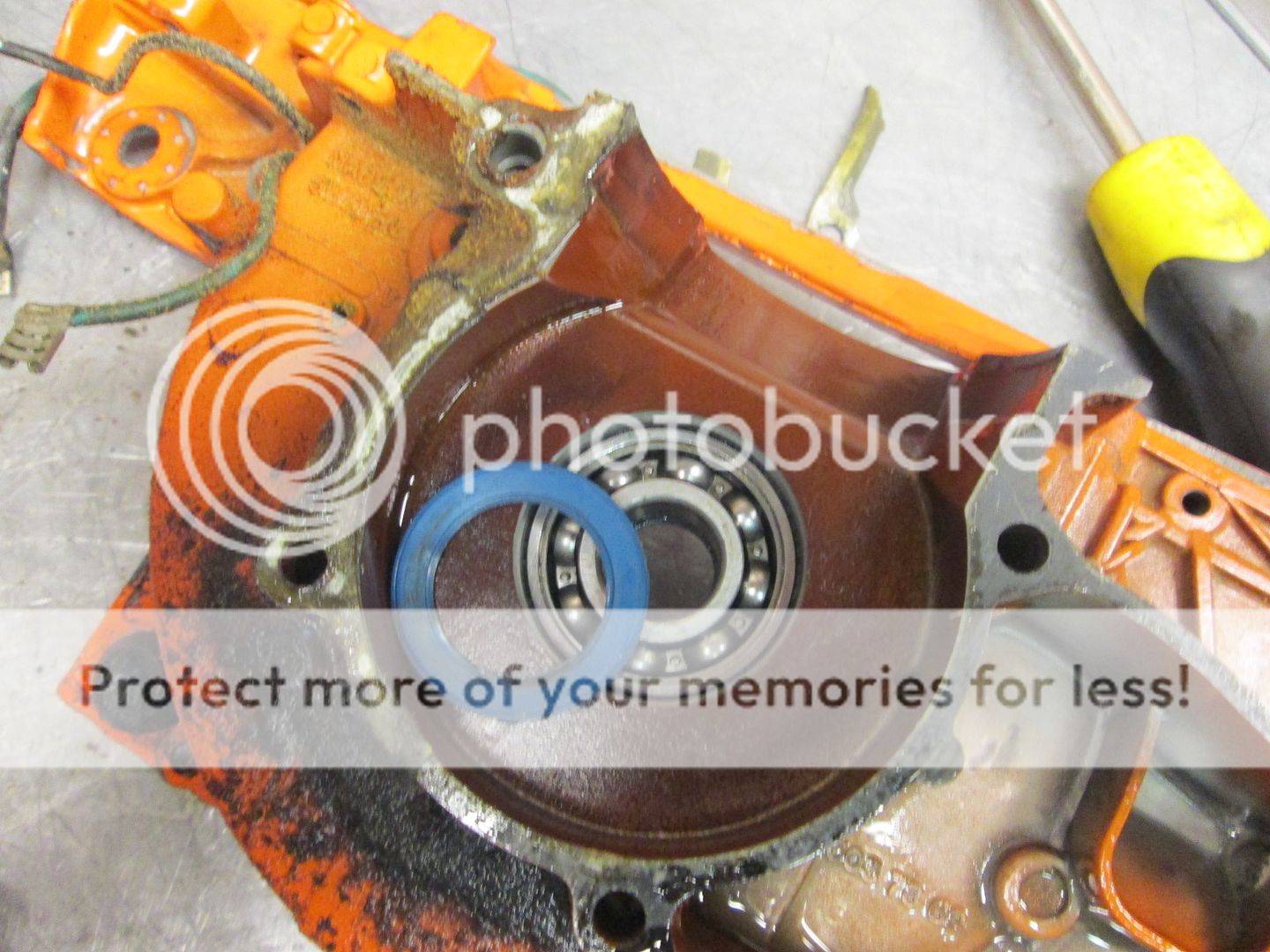

Seal looks a bit off......

http://i1160.photobucket.com/albums/q498/Mastermind7864/Sams%20372/Mtsams3721_zps5f286509.jpg[/IMG]

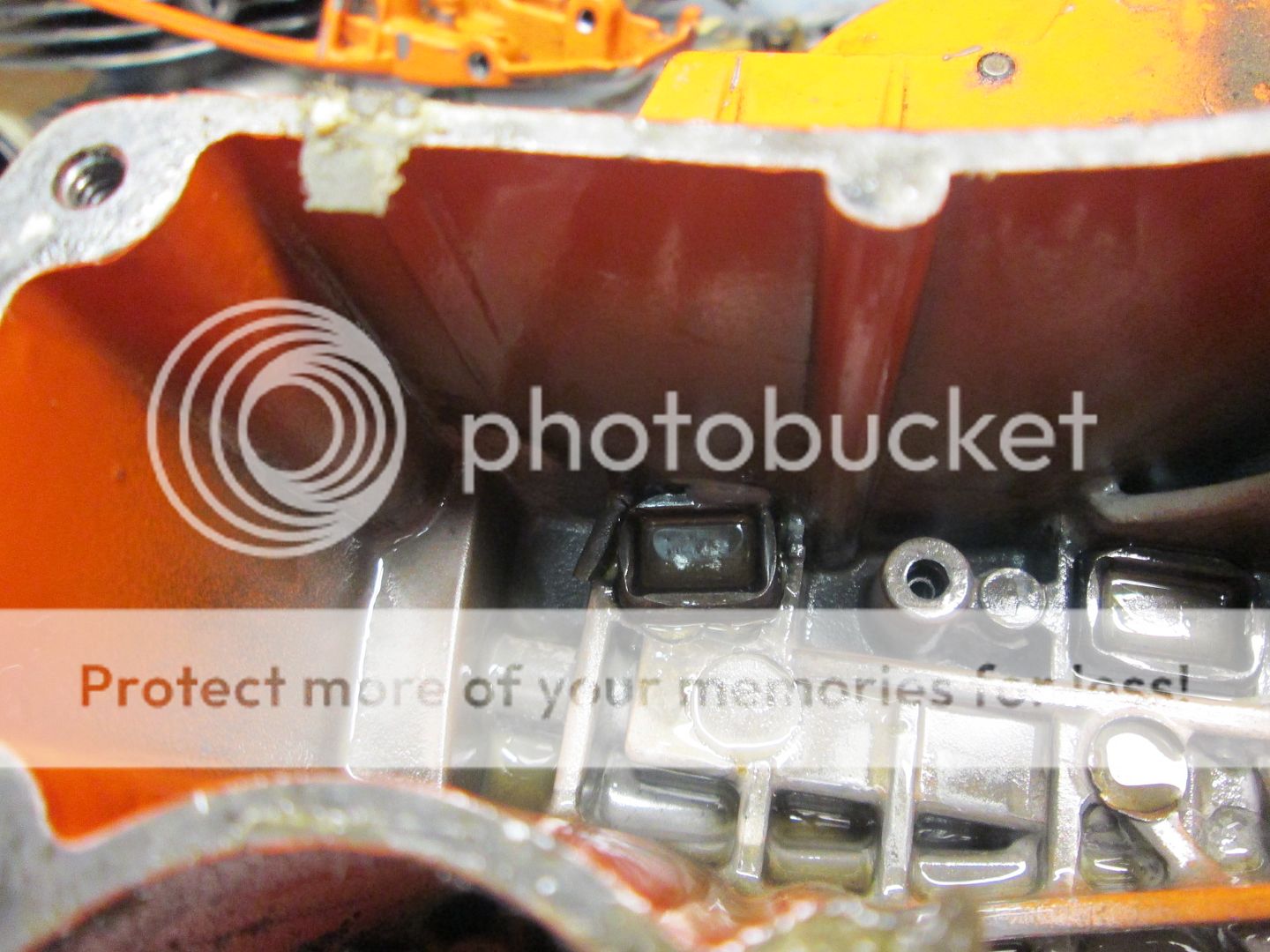

Only one bolt in the coil.......I don't know where the other one is, but I think I know why it didn't stay put.

That's broked.....

Weird......

What brand is this?

It's the one on the left........looks like a nice 372XP.

Seal looks a bit off......

http://i1160.photobucket.com/albums/q498/Mastermind7864/Sams%20372/Mtsams3721_zps5f286509.jpg[/IMG]

Only one bolt in the coil.......I don't know where the other one is, but I think I know why it didn't stay put.

That's broked.....

Weird......

What brand is this?