Tzed250

Addicted to ArboristSite

Is it two of the 6763 and one of the 6816?

Is it two of the 6763 and one of the 6816?

No. You cannot use two of these seals on the flywheel side. They are too thick. I used the original outer seal. The outer seal isn't used on a cart engine, and this saw will not have points. I could have actually left it out. The purpose for the outer seal was discussed some pages back.

Hey Brad, If I were you Id throw that rod bolt on a scale weigh it then grind the other bolt to match the weight. Im not sure what you other fellas think about it but I would like to learn. When building small blocks for my buddies we start with the lightest rod then shave the rest down to its weight. Just helps them hold together. Does it matter on such a small engine? The only thing is in the back of my mind I know what kinda off speed Id be trying to get out of that engine. Ill stop babbling now.

I don't think there's any way to really balance a chainsaw engine. I may be wrong though.

Hey Brad you gonna have it running by this weekend? Seems your back on track.

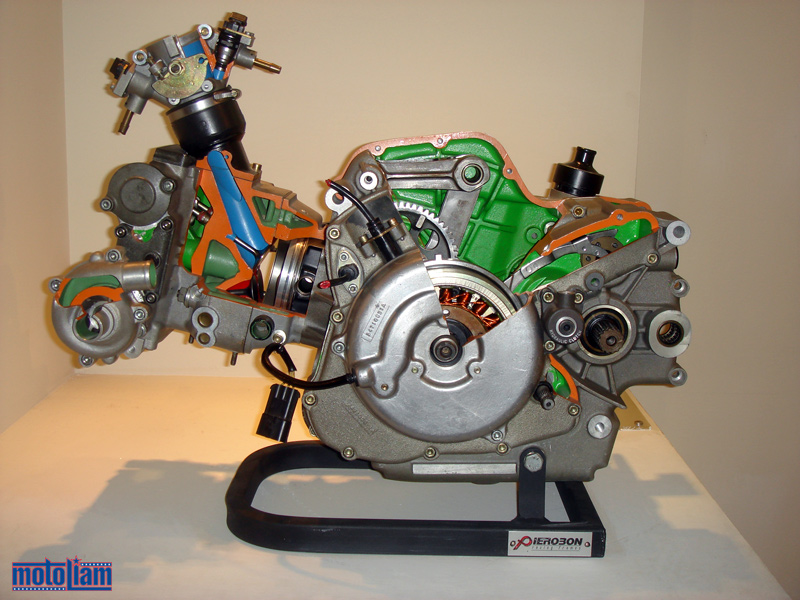

Here is a single with perfect primary balance. Ducati Supermono engine. Notice the second rod 90° from the main rod and piston. The balance rod is toggled to a rocker which dummies a second piston. This engine revved to over 10,000 RPM which is quite high for a 500cc single. The engine had a slight secondary imbalance. A rocking couple induced because the rods sat side-by-side on a common crankpin.

No. You cannot use two of these seals on the flywheel side. They are too thick. I used the original outer seal. The outer seal isn't used on a cart engine, and this saw will not have points. I could have actually left it out. The purpose for the outer seal was discussed some pages back.

Not really correct Buzz. On the Mac's i have rebuilt and thats many.

Both seals go in the same way. There is a hole drilled in the case

that goe's in between the two seals. The idea as i understand is if

the inner sealed had any weepage the second seal would prevent

the weepage from getting into the points but let it exit out the hole

into a felt block that is held in place by one of the points cover lock tabs.

Lee

So are there three different seal part numbers?

Not really correct Buzz. On the Mac's i have rebuilt and thats many.

Both seals go in the same way. There is a hole drilled in the case

that goe's in between the two seals. The idea as i understand is if

the inner sealed had any weepage the second seal would prevent

the weepage from getting into the points but let it exit out the hole

into a felt block that is held in place by one of the points cover lock tabs.

Lee

Enter your email address to join: