You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

08S Restoration

- Thread starter blsnelling

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

The s10 and 08s can both use the same clutch cover part, my S10 came with an 08s clutch cover on it. I don't know if you can put the top shroud cover from and 08s onto an s10, actually I doubt it, the back handle is all plastic on the S10. I think the case is different too. Dave.

pinemartin

tightwad

might not work ???

as a certified welder I must state that cast aluminum is very hard to weld as it tends to harden around weld site and crack 90% of the time. TIG welding is the preferred method for aluninum welding as it provides a clean weld with deep penetration, a aluninum spool gun on a mig welder is another option but is less desirable. If the crack and chip is a big problem than you could send it to me to fix for free if you want to take the 90% gamble on cracks from hardening or saw vibrations.

as a certified welder I must state that cast aluminum is very hard to weld as it tends to harden around weld site and crack 90% of the time. TIG welding is the preferred method for aluninum welding as it provides a clean weld with deep penetration, a aluninum spool gun on a mig welder is another option but is less desirable. If the crack and chip is a big problem than you could send it to me to fix for free if you want to take the 90% gamble on cracks from hardening or saw vibrations.

as a certified welder I must state that cast aluminum is very hard to weld as it tends to harden around weld site and crack 90% of the time. TIG welding is the preferred method for aluninum welding as it provides a clean weld with deep penetration, a aluninum spool gun on a mig welder is another option but is less desirable. If the crack and chip is a big problem than you could send it to me to fix for free if you want to take the 90% gamble on cracks from hardening or saw vibrations.

I appreciate the offer and will keep it in mind. Shipping should be pretty cheap and quick since you're only one state away. I have one local friend that might be able to get it TIGed for me. Would you weld it from the bottom or top? Would you bevel it out any before welding?

Last edited:

pinemartin

tightwad

would bevel from both sides leaving a narrow gap for the top and bottom welds to fuse together eliminating chances for a future crack, standard sheet aluminum would fill the chipped area

pinemartin

tightwad

you did get a good deal on that saw and I see it is being treated how a saw should be. hope it turns out as nice as the rest of your work, I am happy that saw found a good home...

Freakingstang

Doctor Freakinstein

Brad, if you have it welded, make sure you drill a hole at the end of the crack to keep it from spreading after it is welded.

Brad, if you have it welded, make sure you drill a hole at the end of the crack to keep it from spreading after it is welded.

Excellent advise right there. Except in this case, I think it goes all the way across.

pinemartin

tightwad

stopping a crack???

drilling a hole is generally used to stop cracks in glass or ceramics. you shouldn't need a stop hole in any metal if properly prepared before welding. BTW brad is correct the crack does go all the way across so a drill hole would not be needed

drilling a hole is generally used to stop cracks in glass or ceramics. you shouldn't need a stop hole in any metal if properly prepared before welding. BTW brad is correct the crack does go all the way across so a drill hole would not be needed

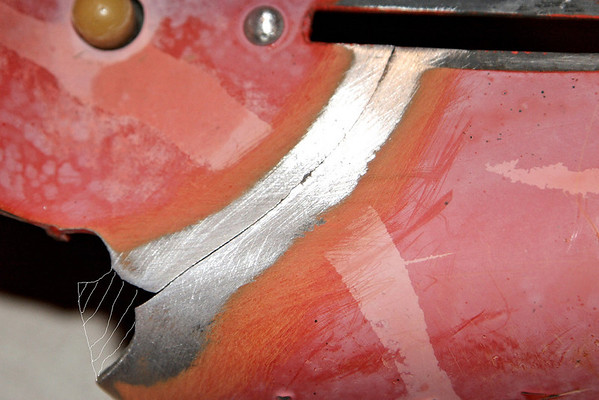

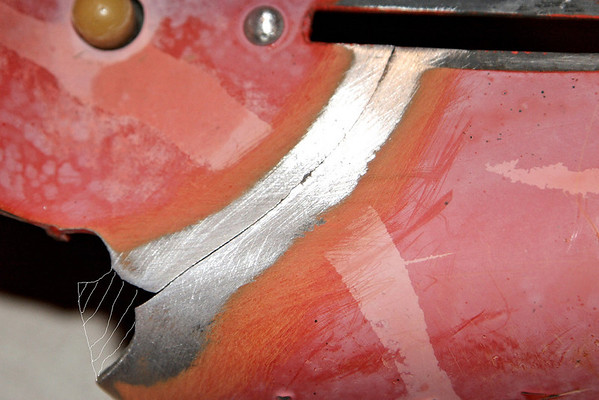

Here's some closeups of the crack. I penciled in the missing material.

Top

Bottom

This is a closeup to show the shape of the missing piece on another shroud. Mine does not have the large hole in it. I'm guessing they changed the kill switch design.

Top

Bottom

This is a closeup to show the shape of the missing piece on another shroud. Mine does not have the large hole in it. I'm guessing they changed the kill switch design.

Pinemartin, I'm ready to take you up on that gamble I talked to my friend who supervises in a machine shop. He told me his welder is great with steel but not with aluminum. PM me your address and I'll get it sent off to you. Should only take a day or two to get up there. Meanwhile, I'll be fixing threads and getting ready for paint on the rest of the saw. The shroud/handle is the only red part on the saw. Everything else is grey.

I talked to my friend who supervises in a machine shop. He told me his welder is great with steel but not with aluminum. PM me your address and I'll get it sent off to you. Should only take a day or two to get up there. Meanwhile, I'll be fixing threads and getting ready for paint on the rest of the saw. The shroud/handle is the only red part on the saw. Everything else is grey.

mag

I thought that Stihl used magnesium?

I thought that Stihl used magnesium?

pinemartin

tightwad

if it is magnesium than brazing or hard silver solder may/should work?

I thought that Stihl used magnesium?

How can I tell other than setting it on fire?

Any tips this morning on how to tell if it's magnesium or aluminum?

Dan Forsh

Addicted to ArboristSite

Any tips this morning on how to tell if it's magnesium or aluminum?

Any chance you could scrape a couple shavings off the damaged edge?

If you can then possibly put a torch to these, if they burn and give off a white flame you know you've got mag alloy.

Lakeside53

Stihl Wrenching

Burning? Thats a difficult test on many mag alloys. And it is an "alloy". The question is "how much" mag is in the AL....

I can usully tell by how it "feels" when drilling it and looking at the shavings fall/float.

It's definitely can be welded -I've seen several with cracks repaired (none "pretty").

I can usully tell by how it "feels" when drilling it and looking at the shavings fall/float.

It's definitely can be welded -I've seen several with cracks repaired (none "pretty").

Would I be better off applying a layer of JB Weld on the bottom side with some screen in it? I'd also put a thin layer on top and sand smooth.

yes.. Smooth means it's worn... if it's not, you'd still see the machining details. The stihl pistons are machined with a specifiec "roughness" to hold lube when new. When these are worn off, it's getting sloppy.

Damn! My 070 piston is a goner then....it is as smooth as er, a baby's bum. It doesn't seem to slop in the piston overly much. I'll have to try with a new one.

Similar threads

- Replies

- 27

- Views

- 3K

- Replies

- 10

- Views

- 2K