Reinforcement?

This is like the ADD third grader suggesting something to the professor, but I was wondering if it would be appropriate to rout a slight recess into the underside of the shroud, then JB a thin piece of high strength alloy to it, then feather out the fill like a car body repair, so that the increased thickness is not noticed without actually measuring it. Just so it could resist the vibration from a non-AV saw. Or would that mess up the collector value, kind of like re-bluing an old gun? Thanks, I really enjoy looking at pictures of your projects.

Gotta go, the short bus is waiting..........

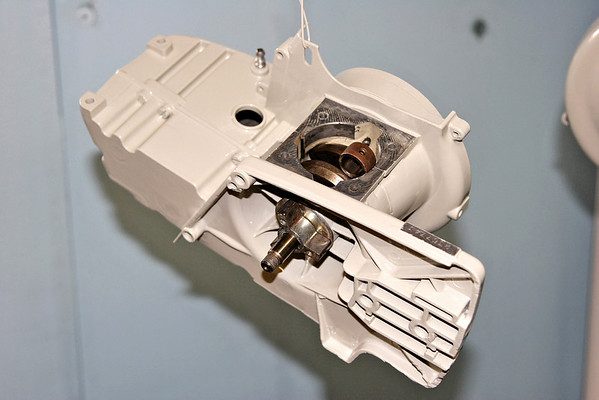

The report from Pinemartin is that the shroud is lovely kirksite, AKA pot metal. It's welded but is going to require some filler to make pretty. Hopefully it'll hold up to the tiny amount of use it'll get.

This is like the ADD third grader suggesting something to the professor, but I was wondering if it would be appropriate to rout a slight recess into the underside of the shroud, then JB a thin piece of high strength alloy to it, then feather out the fill like a car body repair, so that the increased thickness is not noticed without actually measuring it. Just so it could resist the vibration from a non-AV saw. Or would that mess up the collector value, kind of like re-bluing an old gun? Thanks, I really enjoy looking at pictures of your projects.

Gotta go, the short bus is waiting..........

It was hanging upside down. While it was still wet, I wiped it off and shot a little more paint on it. I then went and held it near my garage heater. It flowed right out. I got lucky on that one. Everything else turning out beautiful.

It was hanging upside down. While it was still wet, I wiped it off and shot a little more paint on it. I then went and held it near my garage heater. It flowed right out. I got lucky on that one. Everything else turning out beautiful.