Jeepsnchainsaws

ArboristSite Operative

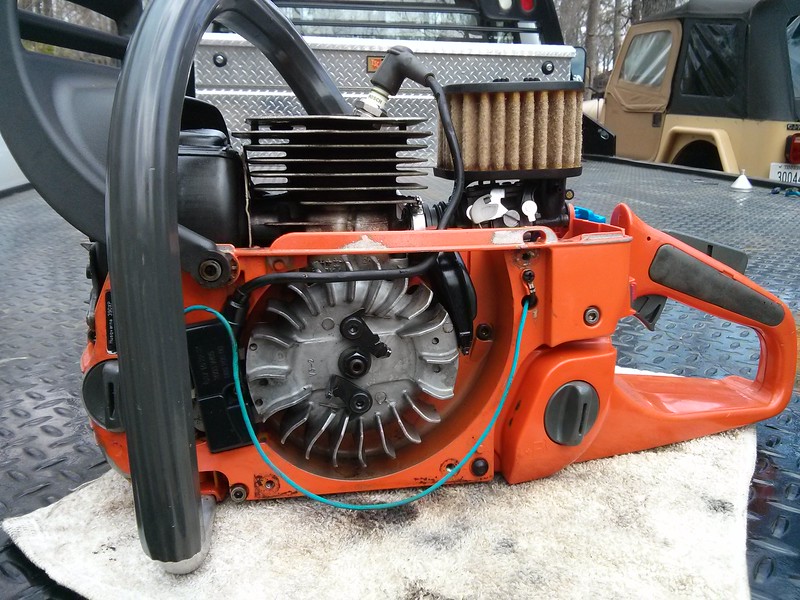

Yeah , I have great luck with mine. They are pretty picky little boogers, they like NEW duck bills and pulse lines regular! I have four that run and LOTS of parts new and used.I was afraid the saw wouldn't oil so I put some thin oil in it. Looks like I better put the sticky stuff in next time. I think I'll tear it down when I get time and check that pulse hose to see why it's got so much pressure in the tank. I may try to run it with the oil pulse line plugged up to see if it helps the idle before I mess with the carb.

I love those little things !