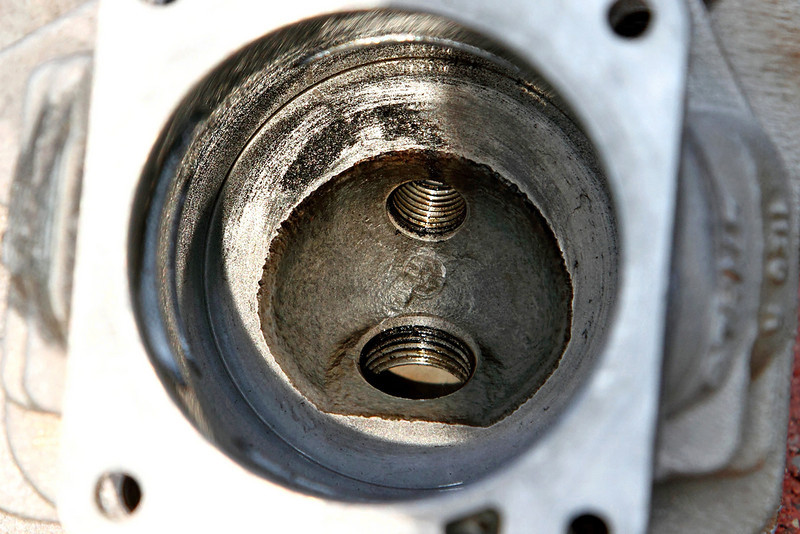

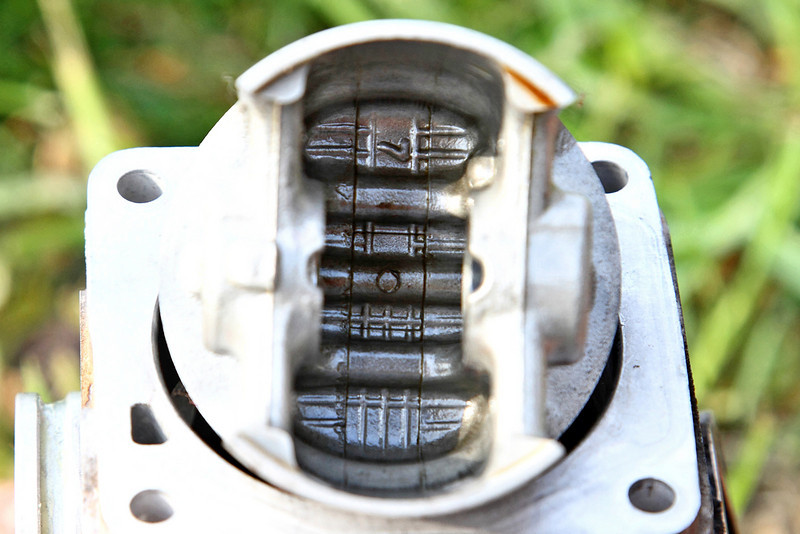

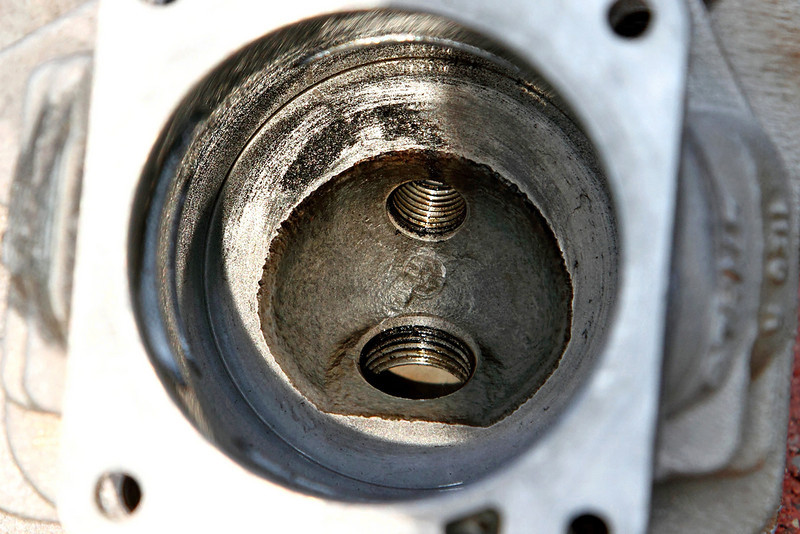

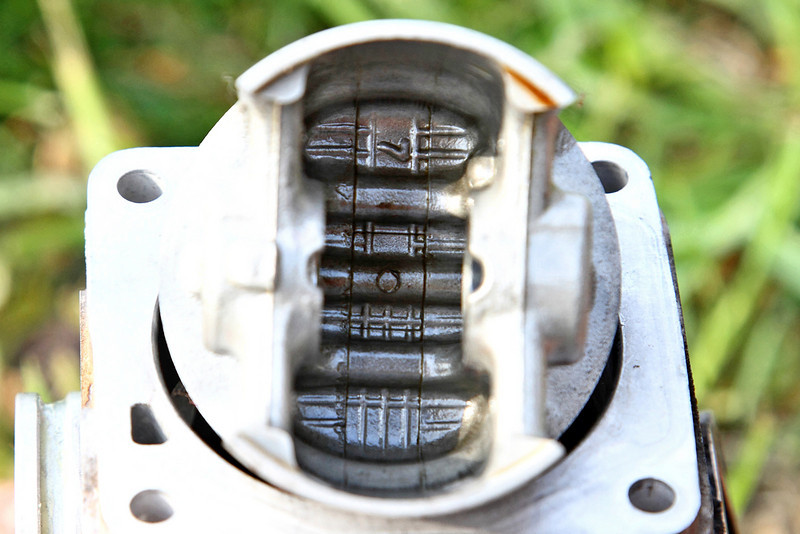

I'm curious as to whether or not this is normal carbon formation on a piston crown. This is the P&C from my new MS440. It has only seen maybe a dozen tanks of fuel. The saw has not been run excessively rich, or lean for that matter. What's odd is the the combustion chamber and exhaust port are both clean. The carbon on the piston crown was extremely hard and very difficult to remove.

Most of you know that I run Klotz R50 at 32:1. My questions are this. Is this normal? If not, is this the result of running R50? Is it the result of running 32:1? What do the masses think. And please don't just blurt out, oh you're running it too rich. Give me a reason why you think what you do.

Most of you know that I run Klotz R50 at 32:1. My questions are this. Is this normal? If not, is this the result of running R50? Is it the result of running 32:1? What do the masses think. And please don't just blurt out, oh you're running it too rich. Give me a reason why you think what you do.