Short version of a long story. I have my father in laws 346xp stripped down. He killed it last year about 4 months after a new piston and rings. I lent him my 346xp a couple weeks ago (which I bought because I liked his so much) with a brand new bar and chain on it. I was over the (his) farm and I almost puked when I saw my saw (no pun...) and and the way he was murdering it. BLAH BLAH BLAH.....I cut up about 8 cords of his nasties rather than let him kill my saw anymore. It was running bad and wouldn't rev but after blowing out the filter and adjusting the carb 5 or 6 times as I cut, it's running ok. It had half the compression it had when I lent it to him and the bar was burned and the chain was chipped up and completely blunt. The more I run it, the better it runs, but the damage is done I think. He's not getting his saw back! I'd like to do a nice build on his and then, maybe, do mine. I have a ton of questions, even after reading you guys for the last two days.

Heres some pics.

Those with weak stomachs, please look away!

Heres some pics.

Those with weak stomachs, please look away!

Intake (see the crack?)

Exhaust.

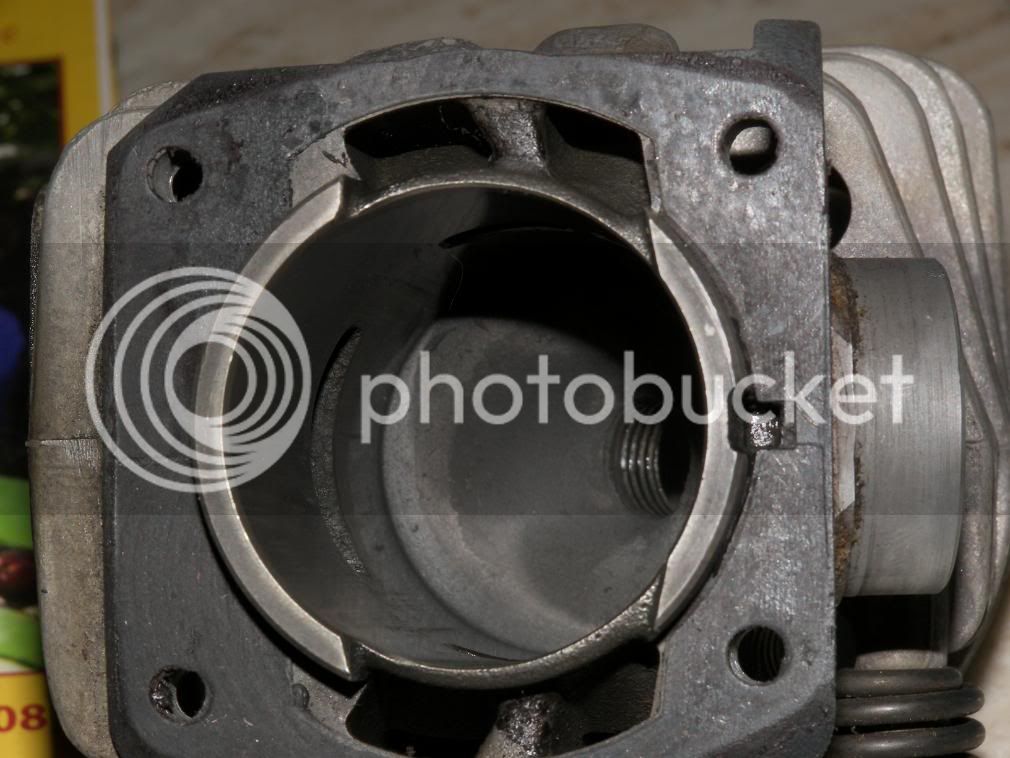

Jug.