jthornton

ArboristSite Guru

I had a good day yesterday and we dropped a standing almost dead red oak that was about 60' tall. I towed the splitter to the tree and parked it right next to the rounds. Sure made life easier on me. In 3 hrs me and Ricky had bucked, split and brought home all the wood. The only thing left was the sawdust. I love my spitter!

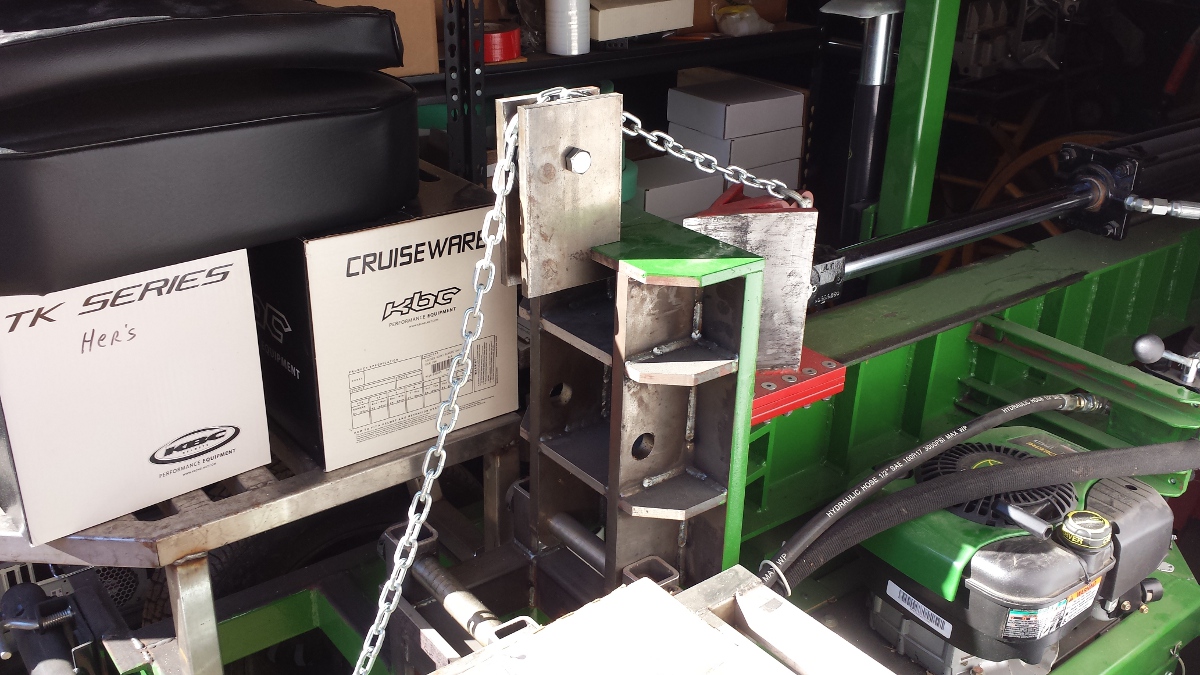

Here is how I mounted the work tables with hitch pins so it is easy to remove.

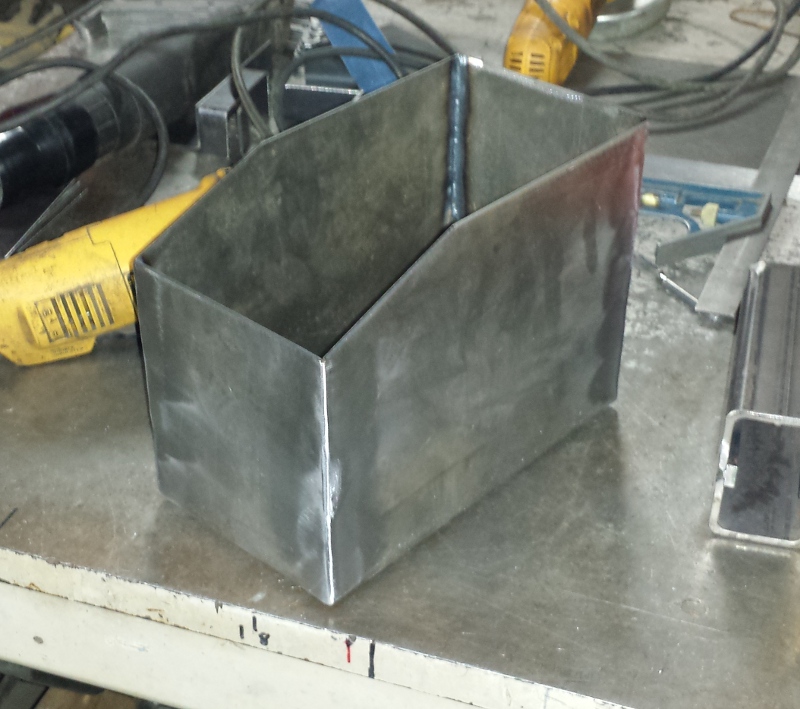

Hooked up and heading to Ricky's house.

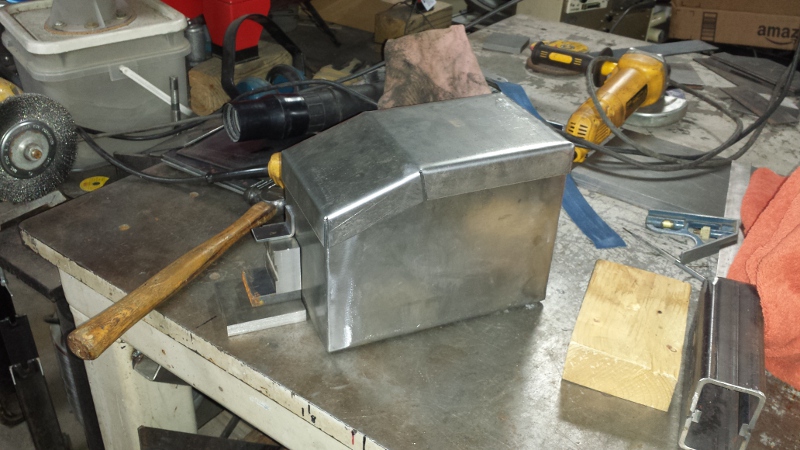

All set up leveled and ready to split. We used my backhoe to make sure the tree fell the way we wanted. It looked a bit heavy on the shop side of the tree and we didn't want it to fall on the shop.

All done and ready to head home.

Here is how I mounted the work tables with hitch pins so it is easy to remove.

Hooked up and heading to Ricky's house.

All set up leveled and ready to split. We used my backhoe to make sure the tree fell the way we wanted. It looked a bit heavy on the shop side of the tree and we didn't want it to fall on the shop.

All done and ready to head home.