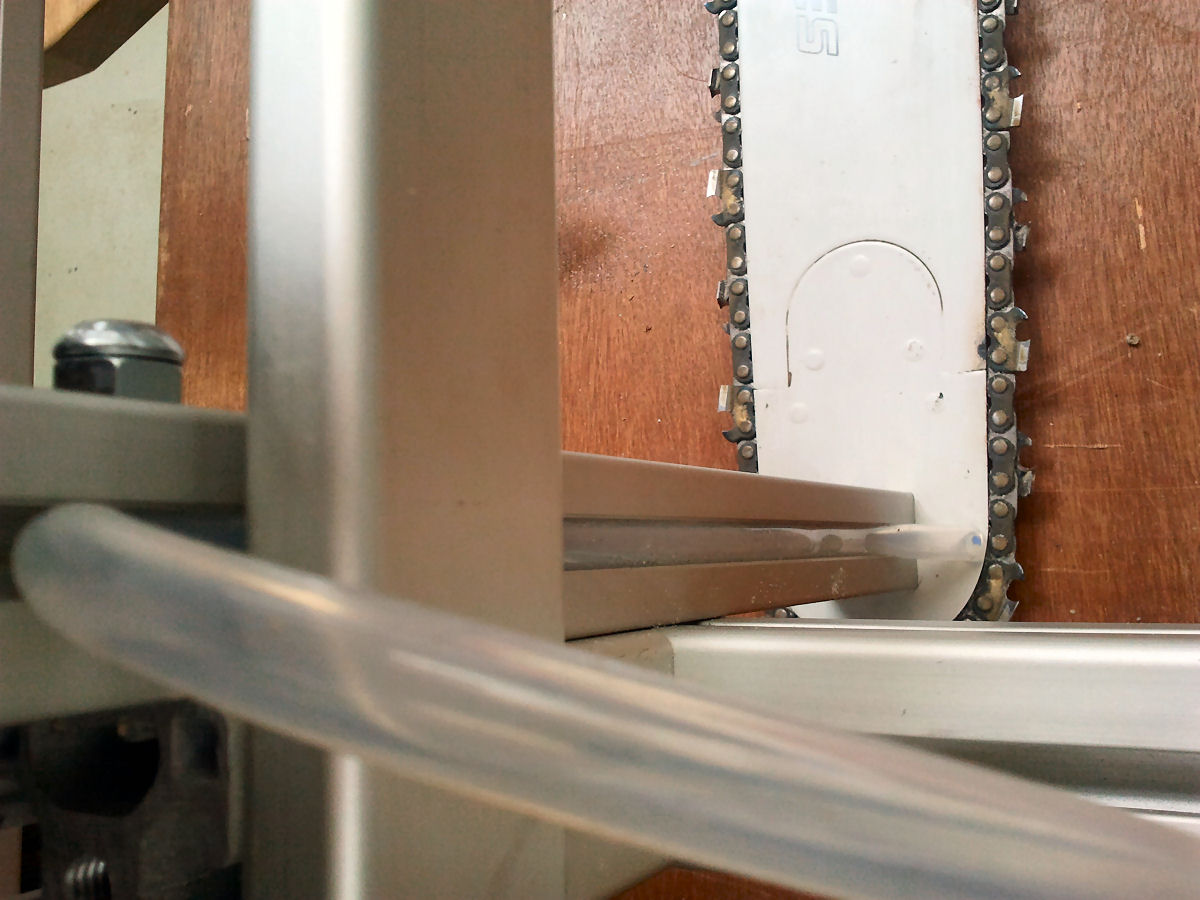

In the first pic, the raker on the left has a flat top but the raker on the right looks like it has never been touched.

What I look at is the ratio of the distance between the cutter and where the raker touches the wood, and the raker depth.

In this picture it's the height of the yellow boxes compare to the length of the boxes.

The one on the left is ~6:1 (which is too low) while the one on the right is 12:1 and this is too high

View attachment 294577

A good working ratio is between 10:1 and 8:1 for softwood

In the second picture the raker depth is too low.

The 3rd picture is hard to judge, but the raker actually measures too high.

With the rakers so erratic the chain will be struggling to cut smoothly and could generate a lot of vibe - this will also all add to the powder dust generation.

All your cutters look like the could use a bit more hook (top plate cutting angle) - This will help the saw self feed better and reduce the amount of pushing required.

I reckon it's better to round the rakers as this reduces friction by allowing them to skate across the wood in the kerf. The corner of a flat top adds some resistance.

What concerns me more than the rakers and the TPCA is the amount of tie base wear on this chain indicating it has been pushed well beyond normal for the amount of wear on these cutters. Either the chain has been run, blunt and the CSM then pushed hard, or without oil, or both.

BTW you don't need to get the whole surface shiny - all you need to do is file enough to remove the glint along the cutting edge - once the glint is gone the rest is wasted metal. Getting the surface shiny without getting rid of the edge glint is a waste of time

What I look at is the ratio of the distance between the cutter and where the raker touches the wood, and the raker depth.

In this picture it's the height of the yellow boxes compare to the length of the boxes.

The one on the left is ~6:1 (which is too low) while the one on the right is 12:1 and this is too high

View attachment 294577

A good working ratio is between 10:1 and 8:1 for softwood

In the second picture the raker depth is too low.

The 3rd picture is hard to judge, but the raker actually measures too high.

With the rakers so erratic the chain will be struggling to cut smoothly and could generate a lot of vibe - this will also all add to the powder dust generation.

All your cutters look like the could use a bit more hook (top plate cutting angle) - This will help the saw self feed better and reduce the amount of pushing required.

I reckon it's better to round the rakers as this reduces friction by allowing them to skate across the wood in the kerf. The corner of a flat top adds some resistance.

What concerns me more than the rakers and the TPCA is the amount of tie base wear on this chain indicating it has been pushed well beyond normal for the amount of wear on these cutters. Either the chain has been run, blunt and the CSM then pushed hard, or without oil, or both.

All that it looks like you are doing is filing a little at the tip of the cutter. You need to file at the intermediate angle all the time otherwise you will never get to the 10º TPFA.I was giving it a few strokes of the file at the current angle, to get the whole surface shiny metal, then giving a last couple of strokes at the lower angle like 20ish, to get closer to a rip profile. A mistake?

BTW you don't need to get the whole surface shiny - all you need to do is file enough to remove the glint along the cutting edge - once the glint is gone the rest is wasted metal. Getting the surface shiny without getting rid of the edge glint is a waste of time

Last edited: