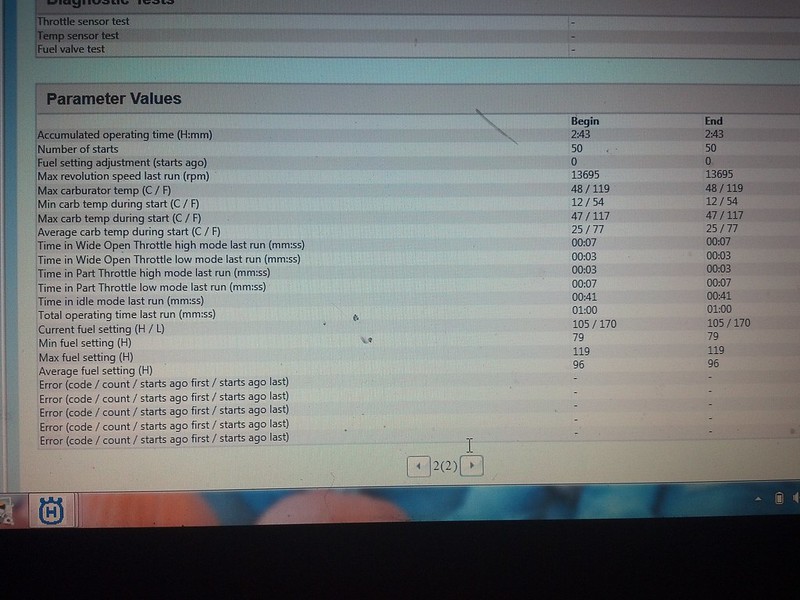

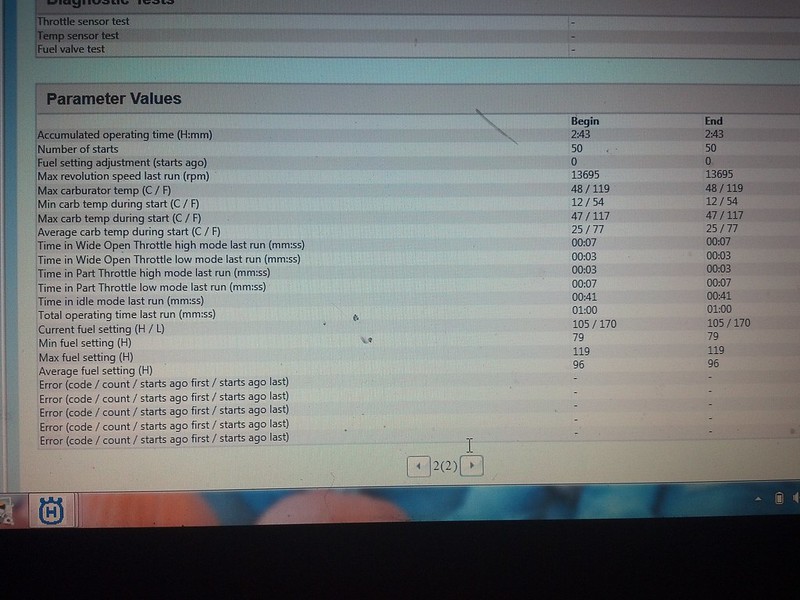

I stole this screen shot from mweba for discussion purposes from the how many hours on your autotune thread. I stopped by TK's today who has my saw to check out the hesitation issue. By the way, my saw wasn't hesitating, it was completely dying off idle. He did the software update, which seemed to help, it now hesitates instead of dying. We got to talking about some of the stats that are shown on this screenshot, but the ones for my saw in particular. He said that from the saws he has plugged in, a lot of the fuel settings are all over the place. And since we are talking about hesitation off idle, we were focused on "current fuel setting (H/L)" for the particular saw shown here (which I have no idea whether it had hesitation issues or not) the L setting is 170. That seems really high compared to the saws he had info on. IIRC there were a lot in the 80's and low hundreds. Mine saw was 32 on the L setting. The lowest by far, and a LOT lower than the saw shown here. Just made me want to bring this up to discuss to see if we collectively could view and analyze data on saws with this issue to see if we can gain some knowledge here. I myself just find the reports pretty interesting. I could stare at them for hours (and still not know what they mean)

By the way my saw has about 7 hours on it and 150 starts and max RPM is 13940.