My next question is how to shift / engage the rack to a spinning gear? I really need to see one of these splitters. I would love to see some pics.

I have been told my Gripo is a super split that's cheaper for the Canadian market.

2500$ for a new one.

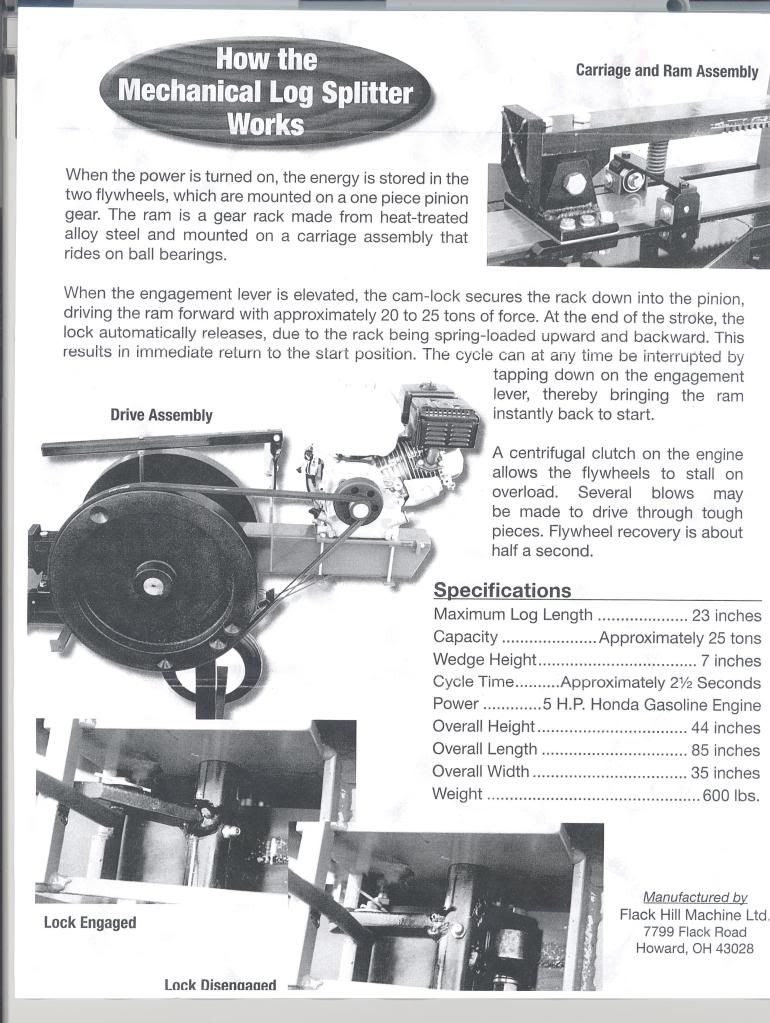

If this is true then the handle you pull up is a spring loaded cam lobe that forces the "rack" downward to engage with the constantly spinning "pinion" thats attached to the flywheels.

The rack gets flung toward the wood but is short so it passes by the cam, which drops even further, but then it releases, and the spring return pressure causes it to all lift once again.

During this whole process the rack has a spring attached to it, and once it disengages from the pinion the spring retracts the rack to its place of rest.

Rubber stoppers cushion the return blow.

I've replaced both stoppers, broken the return spring 4 times, just keep shortening it, but now its beyond repair, the bearing that travels with rack has been replaced, bolts have all come out on pusher head with thread, I've welded them all now, arm that holds bearing has broken, The eccentric cams that adjust the clearance for the brass shim that the pusher head rides on continually loosen, one side is still tighter than the other.

Bolts all rattle out on the cover and belts are shredding...

Wood slivers and dirt/snow are more than enough to stop the head from returning, so your constantly cleaning and sometimes just the tiniest bit of oil is needed to keep the bearing from seizing.

9/16 is a must in your pocket for those cams.But you have to take the springs off to adjust PITA

I bought barely used two years ago for 1500 and I've put maybe 80 cord through it.

Reminds me. I've got to order some parts.